In sieve analysis, the most common sources of error are not random but systematic, stemming from the sample's condition, the equipment's integrity, and the operator's procedure. While a robust technique, its apparent simplicity can mask critical details. An inaccurate result is often caused by an overloaded sieve, insufficient shaking time, or using a sample that isn't truly representative of the entire batch.

Sieve analysis remains a cornerstone of particle size measurement due to its simplicity and low cost. However, its reliability is not inherent to the method itself; it is a direct result of meticulous preparation, procedural consistency, and a clear understanding of its fundamental limitations.

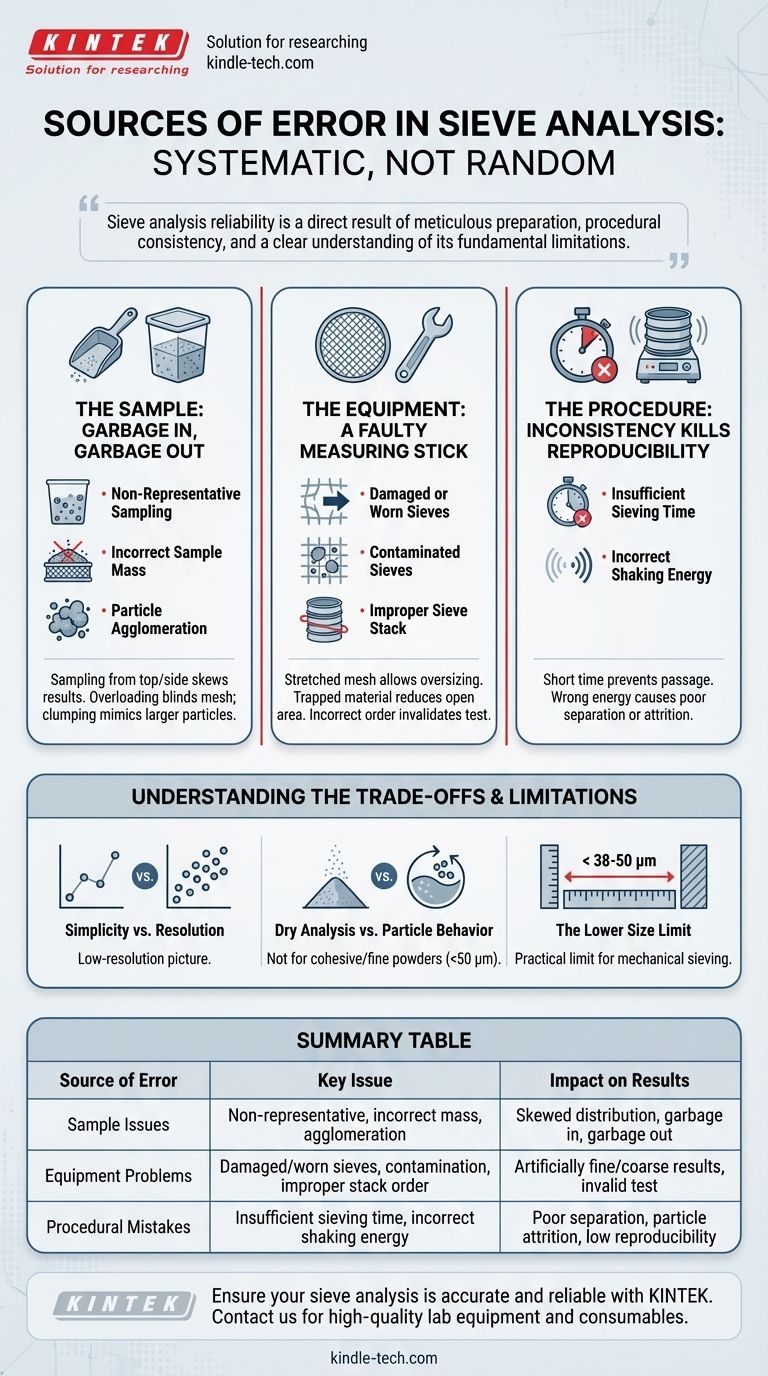

Understanding the Root Causes of Inaccuracy

Errors in sieve analysis can be categorized into three main areas. Understanding these allows you to troubleshoot issues and ensure your results are dependable.

The Sample: Garbage In, Garbage Out

The single greatest source of error often occurs before the test even begins. If the sample placed in the sieve stack doesn't accurately represent the bulk material, the results are meaningless.

- Non-Representative Sampling: Taking a sample just from the top or side of a container can lead to skewed results, as smaller particles may have settled to the bottom during transit or storage. Proper sampling techniques, like using a sample splitter (riffle box), are critical.

- Incorrect Sample Mass: Overloading a sieve by using too much sample is a very common mistake. It blinds the mesh, preventing particles from having a fair chance to pass through and resulting in a falsely coarse distribution. Conversely, too little sample can be statistically insignificant.

- Particle Agglomeration: The method assumes particles are individual and free-flowing. If particles are clumped together due to moisture or static electricity, these agglomerates will behave like larger particles, skewing the results toward the coarse end.

The Equipment: A Faulty Measuring Stick

The sieves themselves are precision instruments. If they are not maintained, they will produce faulty data.

- Damaged or Worn Sieves: A stretched, torn, or dented mesh will have apertures that are larger than specified. This allows oversized particles to pass through to a finer sieve, leading to an artificially fine particle size distribution.

- Contaminated Sieves: Mesh that is not thoroughly cleaned after each use can retain particles. This trapped material (blinding) effectively reduces the open area of the sieve, preventing other particles from passing and skewing the result.

- Improper Sieve Stack: A stack of sieves must be assembled in descending order of aperture size, with the finest sieve at the bottom followed by a solid pan. An incorrect order invalidates the entire test.

The Procedure: Inconsistency Kills Reproducibility

Even with a perfect sample and pristine equipment, inconsistent execution will lead to unreliable data that cannot be compared over time.

- Insufficient Sieving Time: Particles need sufficient time and energy to find an aperture. If the shaking duration is too short, many particles will not have the opportunity to pass through their correct sieve, leading to them being weighed on a coarser screen than they should be.

- Incorrect Shaking Energy: The amplitude and type of shaking motion (e.g., tapping vs. orbital) are critical variables. Too little energy prevents effective separation; too much energy can cause particle attrition (breakdown) or cause elongated particles to bounce and fail to pass through.

Understanding the Trade-offs

It is crucial to distinguish between procedural errors, which can be fixed, and inherent limitations of the method.

Simplicity vs. Resolution

Sieve analysis is straightforward but provides a low-resolution picture. A standard stack may only have 6-8 sieves, meaning your entire particle size distribution is based on a handful of data points. This is a stark contrast to methods like laser diffraction, which can provide hundreds of data points for a much more detailed curve.

Dry Analysis vs. Particle Behavior

The standard method is designed for dry, free-flowing powders. This is a significant limitation. It cannot be used for emulsions, slurries, or powders that are cohesive or prone to electrostatic charge without specialized techniques like wet sieving, which introduces its own complexities.

The Lower Size Limit

Mechanical sieving has a practical lower limit of around 38-50 microns (µm). Below this size, the tiny forces between particles (like static and cohesion) become stronger than the gravitational forces needed for them to pass through the mesh. Attempting to measure particles finer than this will lead to severe sieve blinding and inaccurate results.

Making the Right Choice for Your Goal

To obtain reliable data, you must align your procedure with your analytical objective.

- If your primary focus is routine quality control: Standardize your procedure relentlessly. Use the exact same sample mass and sieving time for every test to ensure your results are consistent and comparable over time.

- If your primary focus is accurate material characterization: Prioritize using a representative sample via a sample splitter and perform regular inspections of your sieves for any signs of damage or wear.

- If your primary focus is analyzing very fine or cohesive powders (< 50 µm): Recognize the fundamental limitations of dry sieving and consider an alternative method, such as laser diffraction, that is better suited for fine particles.

Ultimately, the accuracy of your sieve analysis is a direct reflection of the care taken in its execution.

Summary Table:

| Source of Error | Key Issue | Impact on Results |

|---|---|---|

| Sample Issues | Non-representative sampling, incorrect mass, agglomeration | Skewed distribution, 'garbage in, garbage out' |

| Equipment Problems | Damaged/worn sieves, contamination, improper stack order | Artificially fine/coarse results, invalid test |

| Procedural Mistakes | Insufficient sieving time, incorrect shaking energy | Poor separation, particle attrition, low reproducibility |

Ensure your sieve analysis is accurate and reliable with KINTEK.

Accurate particle size data is critical for your lab's quality control and material characterization. KINTEK specializes in providing high-quality lab equipment and consumables, including precision sieves and sample preparation tools, to help you avoid common errors and achieve consistent, dependable results.

Our experts can help you select the right equipment and optimize your procedures for your specific materials and goals. Don't let sieve analysis errors compromise your data—contact us today to discuss your laboratory needs and how we can support your success.

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

People Also Ask

- What is the difference between wet sieve analysis and dry sieve analysis? Choose the Right Method for Your Material

- How does a standard test sieve contribute to the preparation of BCZYYb electrolyte powders? Enhance Particle Uniformity

- What is the purpose of using wide-aperture sieving screens? Optimize Garden Waste Pretreatment for Quality Pellets

- How can we separate different sized particles by sieving? A Guide to Accurate Particle Size Distribution

- What are the two methods of sieve analysis? Choose the Right Method for Accurate Particle Sizing

- What are the methods of sieve analysis? Master the Standard Process for Particle Size Distribution

- What is the importance of particle size analysis by sieving? Ensure Product Quality and Performance

- Why use specific mesh metal sieves for activated carbon in MDHP? Ensure Stable Microwave Resonance & Hydrogen Yield