In short, the primary piece of equipment is a Sieve Shaker. This machine is designed to hold a stack of test sieves and agitate them in a consistent, repeatable manner. Its purpose is to ensure that particles have ample opportunity to pass through the sieve openings, leading to an accurate and reliable particle size distribution analysis.

A mechanical sieve shaker is the core of the operation, but it is only one component. Achieving a trustworthy sieve analysis depends on a complete system of calibrated equipment, including the sieves themselves, a precision balance, and proper collection tools.

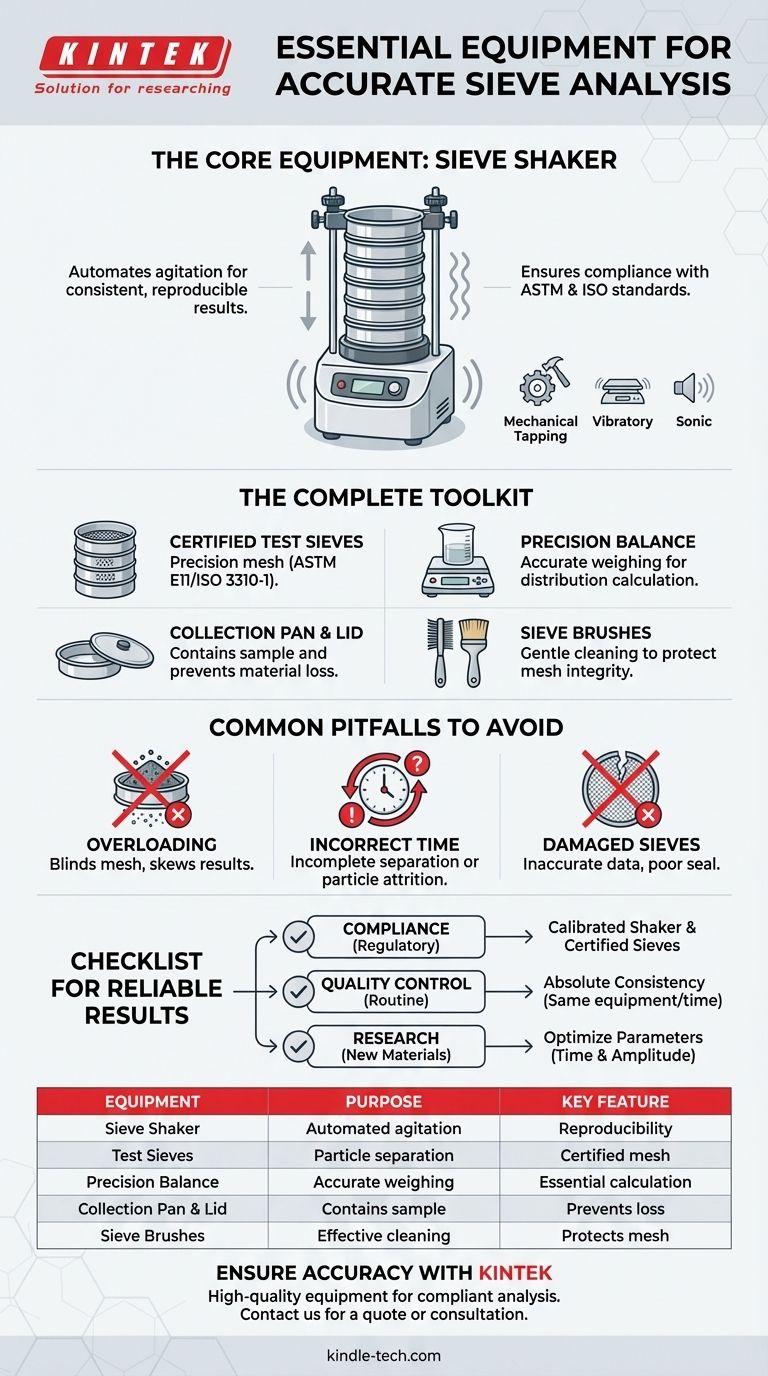

The Core Equipment: The Sieve Shaker

A sieve shaker automates the most critical step of the sieving process: agitation. Relying on manual shaking is inefficient and introduces significant variability, making it impossible to compare results accurately over time or between different operators.

What is a Sieve Shaker?

A sieve shaker is a motorized device that imparts a specific motion to a stack of sieves. This motion ensures the entire surface of each sieve is utilized and that particles are constantly reoriented to find an opening.

The machine securely clamps the sieve stack, which consists of several sieves with progressively smaller mesh openings, a lid on top, and a solid collection pan at the bottom.

Why is Mechanical Shaking Necessary?

The goal of a sieve test is reproducibility. Mechanical shakers eliminate the human element and guarantee that every sample is subjected to the exact same shaking duration, intensity, and motion.

This consistency is essential for meeting industry standards like ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization), which mandate controlled testing procedures.

Common Types of Sieve Shakers

While all shakers serve the same basic function, they use different motions. The most common is a mechanical tapping shaker (like the classic Ro-Tap®), which combines a horizontal circular motion with a vertical tapping motion.

Other types include vibratory shakers, which use an electromagnetic drive to create a 3D throwing motion, and sonic shakers, which use high-frequency vibrations for very fine or delicate powders.

The Complete Toolkit for Accurate Sieve Analysis

The shaker is central, but it's useless without the other essential components. A proper test requires a full set of carefully selected and maintained equipment.

Test Sieves

This is the most obvious component. Test sieves are high-precision instruments, typically with a stainless steel mesh and a brass or stainless steel frame. Each must be certified to meet standards like ASTM E11 or ISO 3310-1.

They are arranged in a "stack" from the largest mesh opening at the top to the smallest at the bottom.

Balance or Scale

Accurate weighing is non-negotiable. You need a laboratory balance with sufficient precision to weigh the raw sample and the material retained on each individual sieve after shaking. The results are calculated based on these weights.

Collection Pan and Lid

These simple components are critical. The lid is placed on the top sieve to prevent any loss of the sample material during agitation.

The collection pan, or "receiver," sits at the very bottom of the stack to collect the finest particles that pass through all the sieves.

Sieve Brushes

Proper cleaning is essential for accuracy and for preserving the lifespan of your expensive test sieves. Specialized brushes—typically one with stiff bristles for coarse mesh and one with soft bristles for fine mesh—are used to gently dislodge particles without damaging the delicate wire mesh.

Understanding the Common Pitfalls

Using the right equipment is only half the battle. Avoiding common procedural errors is just as important for generating reliable data.

Overloading the Sieves

Placing too much sample material onto the sieve stack is the most frequent mistake. An overloaded sieve "blinds" the mesh, preventing particles from passing through even if they are small enough. This skews the results, showing an artificially coarse distribution.

Incorrect Shaking Time

Every material has an optimal sieving time. Too little time results in incomplete separation. Too much time can be inefficient and, for some friable materials, can actually cause particles to break down (attrition), creating more fines and distorting the results.

Using Damaged Sieves

Always inspect your sieves before use. A stretched, torn, or sagging mesh is no longer a precision instrument. Dents in the frame can prevent a proper seal within the stack, allowing material to leak between sieves.

A Checklist for a Reliable Sieve Test

To ensure your results are accurate and defensible, select your approach based on your primary objective.

- If your primary focus is regulatory compliance or certification: You must use a calibrated sieve shaker and certified sieves (ASTM/ISO) and follow a documented, standardized procedure for sample size and shaking time.

- If your primary focus is routine internal quality control: The key is absolute consistency. Use the exact same equipment, sample weight, and shaking time for every test to ensure your day-to-day results are comparable.

- If your primary focus is research with new materials: You may need to experiment to find the optimal shaking time and amplitude that provides complete separation without causing particle degradation.

By understanding each component's role and adhering to a consistent procedure, you transform a simple test into a powerful tool for material characterization.

Summary Table:

| Equipment | Purpose | Key Feature |

|---|---|---|

| Sieve Shaker | Automated, consistent agitation | Ensures reproducibility (ASTM/ISO) |

| Test Sieves | Particle separation | Certified mesh (ASTM E11/ISO 3310-1) |

| Precision Balance | Accurate sample weighing | Essential for calculating distribution |

| Collection Pan & Lid | Contains sample and fines | Prevents material loss |

| Sieve Brushes | Gentle, effective cleaning | Protects sieve mesh integrity |

Ensure your sieve analysis is accurate and compliant with the right equipment from KINTEK.

As a specialist in laboratory equipment, KINTEK provides high-quality sieve shakers, certified test sieves, and precision balances designed to meet ASTM and ISO standards. Whether your focus is rigorous quality control, regulatory compliance, or research and development, our solutions deliver the consistency and reliability you need for trustworthy particle size distribution data.

Contact us today to discuss your specific application and let our experts help you build a complete, reliable sieving setup. Get in touch via our contact form to request a quote or schedule a consultation.

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

People Also Ask

- What is the principle of sieving machine? Achieve Accurate Particle Size Separation

- What is the primary function of standard sieving systems? Master Matrix Uniformity for Advanced Composites

- What is the use of vibratory sieve shaker? Achieve Precise Particle Size Analysis for Your Lab

- What is the significance of using a laboratory constant-temperature shaker in corrosion inhibitor biodegradation study?

- How does a precision vibration sieving system influence Fe-Al thermal spray feedstocks? Optimize Particle Distribution

- What is the role of a precision sieving system in Ag3PO4 preparation? Optimize Phosphate Extraction Efficiency

- What is the purpose of using a high-energy shaker mill for Na2B12H12? Unlock Peak Ionic Conductivity

- What is the primary function of a mechanical sieve shaker for biomass analysis? Optimize Particle Size Distribution