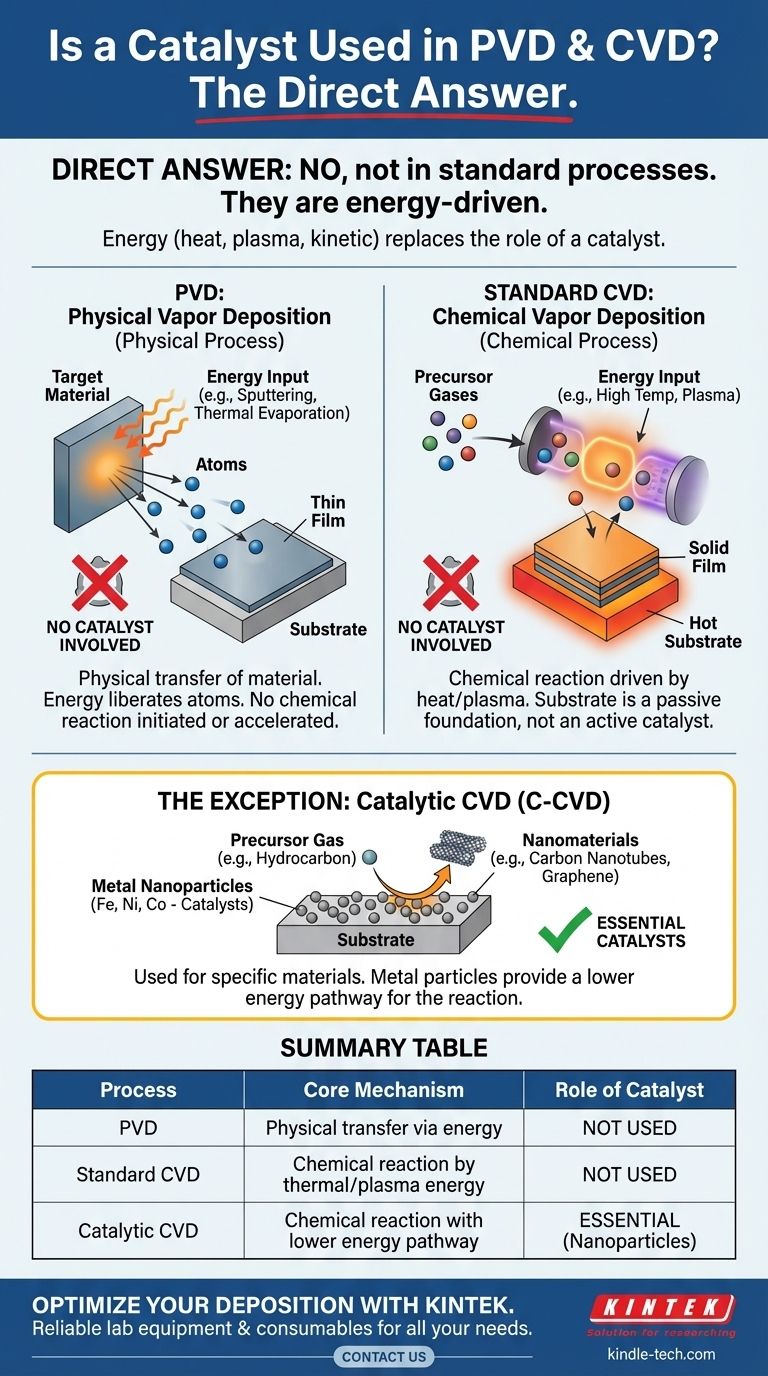

To be direct, this is a common point of confusion stemming from a misunderstanding of how these processes work. Neither Physical Vapor Deposition (PVD) nor conventional Chemical Vapor Deposition (CVD) uses a catalyst. These techniques are driven by direct energy input—such as heat, plasma, or kinetic energy—not by a catalytic reaction.

The core misconception is that PVD and CVD require a catalyst like many traditional chemical reactions. The reality is that these are energy-driven processes where thermal or kinetic energy forces a material to deposit onto a surface, fundamentally replacing the role of a catalyst.

The Role of Energy, Not Catalysts, in Deposition

To understand why catalysts are not part of the standard PVD or CVD equation, you must first distinguish between their core mechanisms. One is a physical process, and the other is a chemical one, but both rely on energy to function.

How PVD Works: A Purely Physical Process

PVD physically transfers a material from a source (called a target) to a substrate without a chemical reaction.

The two most common P_VD techniques are thermal evaporation and sputtering. In both cases, the energy input is what liberates atoms from the source material.

No catalyst is involved because no chemical reaction is being initiated or accelerated. The process is akin to boiling water to create steam that condenses on a cold lid—it's a change of physical state, not a chemical transformation.

How CVD Works: An Energy-Driven Chemical Process

CVD uses a chemical reaction to create a thin film, but this reaction is typically triggered by high temperatures or plasma, not a catalyst.

In this process, volatile precursor gases are introduced into a reaction chamber. The intense heat causes these gases to react or decompose upon contacting the hot substrate, leaving behind a solid film.

While the reaction occurs on the substrate's surface, the substrate itself is merely the foundation for film growth. It is not a catalyst because it does not actively speed up the reaction in a catalytic cycle.

Understanding the Exception: Catalytic CVD

While standard CVD and all PVD processes are non-catalytic, there is a specific and important subclass of CVD where catalysts are essential. This distinction is critical to avoiding confusion.

The Special Case: Catalytic CVD (C-CVD)

For the synthesis of specific materials, most notably carbon nanotubes and graphene, a technique called Catalytic CVD (C-CVD) is used.

In this method, tiny nanoparticles of metals (like iron, nickel, or cobalt) are deposited on the substrate first. These metal particles act as true catalysts.

The precursor gas (e.g., a hydrocarbon like acetylene) preferentially decomposes on the surface of these metal nanoparticles, which provides a lower energy pathway for the reaction to occur, enabling the growth of the desired nanostructure.

Substrate vs. Catalyst

It's crucial not to confuse the substrate with a catalyst.

A substrate is the base material upon which the thin film is grown. It is a passive foundation.

A catalyst, as used in C-CVD, is an active agent that participates in and accelerates a chemical reaction without being consumed in the final product.

Key Principles for Understanding Deposition

To determine the driving force of a given process, focus on the fundamental mechanism that enables the deposition of the thin film.

- If your process is PVD: The key factor is the physical energy source (e.g., heat for evaporation or ion bombardment for sputtering) that turns the solid target into a vapor.

- If your process is conventional CVD: The key factors are the precursor gases and the thermal or plasma energy that drives their chemical reaction on the substrate surface.

- If you are growing specific nanomaterials like carbon nanotubes: You are likely dealing with Catalytic CVD (C-CVD), where metal nanoparticles are the essential catalysts.

Ultimately, understanding the fundamental driving force—whether physical energy, thermal energy, or a true catalyst—is the key to mastering thin-film deposition techniques.

Summary Table:

| Process | Core Mechanism | Role of Catalyst |

|---|---|---|

| PVD (Physical Vapor Deposition) | Physical transfer via energy (heat, plasma) | Not Used |

| Standard CVD (Chemical Vapor Deposition) | Chemical reaction driven by thermal/plasma energy | Not Used |

| Catalytic CVD (C-CVD) | Chemical reaction with a lower energy pathway | Essential (e.g., Fe, Ni, Co nanoparticles) |

Optimize Your Thin-Film Deposition Processes with KINTEK

Understanding the precise mechanisms behind PVD and CVD is crucial for achieving consistent, high-quality results in your laboratory. Whether you are working with standard coatings or advanced nanomaterials, having the right equipment and consumables is key.

KINTEK specializes in providing reliable lab equipment and consumables for all your deposition needs. We can help you select the perfect system for your application, ensuring efficiency and precision.

Contact us today to discuss how our solutions can enhance your research and development. Let our experts guide you to the right technology for your specific challenges.

Get in touch via our Contact Form to speak with a specialist!

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What is the precursor gas in PECVD? The Key to Low-Temperature Thin Film Deposition

- Why is PECVD better than CVD? Achieve Superior Low-Temperature Thin Film Deposition

- What is the difference between thermal CVD and PECVD? Choose the Right Thin-Film Deposition Method

- What are the advantages of PECVD over CVD? Achieve High-Quality Thin Films at Lower Temperatures

- How is PECVD different from CVD? Unlock Low-Temperature Thin Film Deposition