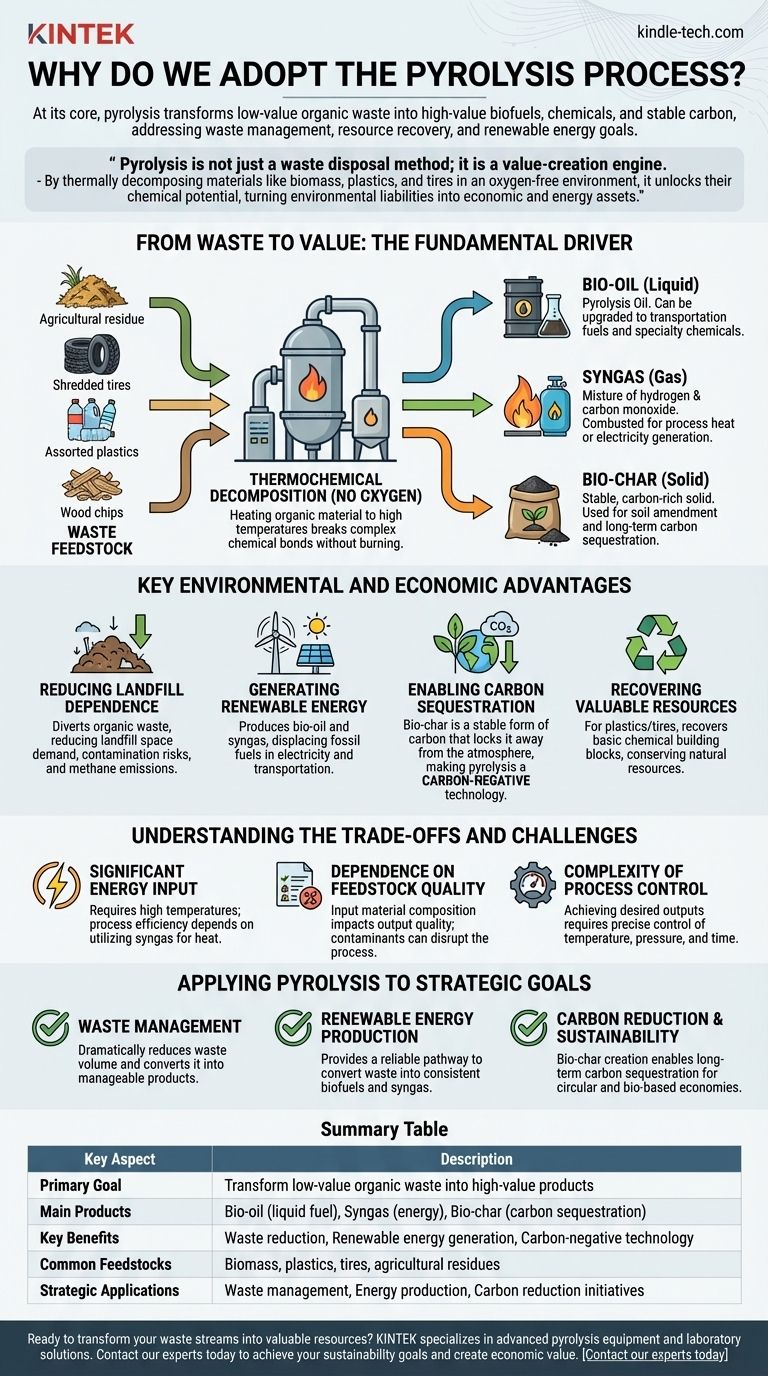

At its core, the pyrolysis process is adopted because it is a powerful method for transforming low-value organic waste into high-value products like biofuels, chemicals, and stable carbon. It provides a comprehensive solution that addresses critical, interconnected challenges in waste management, resource recovery, and the transition to renewable energy sources.

Pyrolysis is not just a waste disposal method; it is a value-creation engine. By thermally decomposing materials like biomass, plastics, and tires in an oxygen-free environment, it unlocks their chemical potential, turning environmental liabilities into economic and energy assets.

The Fundamental Driver: From Waste to Value

Pyrolysis is fundamentally a technology of transformation. It works by changing the chemical structure of materials, which allows us to reclaim value from what would otherwise be discarded.

Deconstructing Materials Without Burning

The process involves thermochemical decomposition, which means heating organic material to high temperatures in the complete or near-complete absence of oxygen.

Because there is no oxygen, the material does not combust or burn. Instead, the heat breaks the complex chemical bonds, deconstructing the material into simpler, more valuable molecules.

Creating a Versatile Product Slate

This deconstruction process yields three distinct and useful outputs, with the exact proportions depending on the feedstock and operating conditions.

- Bio-oil (Liquid): A dark, dense liquid often called pyrolysis oil. It can be upgraded into transportation fuels or used as a source for specialty chemicals, offering a direct alternative to petroleum.

- Syngas (Gas): A mixture of combustible gases, primarily hydrogen and carbon monoxide. This gas can be burned on-site to power the pyrolysis process itself or used to generate heat and electricity.

- Bio-char (Solid): A stable, carbon-rich solid similar to charcoal. This material has a growing list of applications, from soil amendment to a tool for carbon sequestration.

Key Environmental and Economic Advantages

The decision to adopt pyrolysis is driven by a unique combination of environmental stewardship and economic opportunity. It solves multiple problems at once.

Reducing Landfill Dependence

Pyrolysis provides a highly effective alternative to landfills for a wide range of organic wastes, including agricultural residue, wood waste, scrap tires, and certain plastics.

By diverting this material, it reduces the demand for landfill space, minimizes the risk of soil and water contamination, and mitigates the release of methane, a potent greenhouse gas.

Generating Renewable Energy

The bio-oil and syngas produced are forms of renewable energy. They can displace fossil fuels in electricity generation, industrial heating, and transportation.

This helps reduce dependence on finite fossil resources and decreases the air pollution and greenhouse gas emissions associated with burning them.

Enabling Carbon Sequestration

The production of bio-char is one of the most significant environmental benefits. Bio-char is a highly stable form of carbon that resists decomposition for hundreds or even thousands of years.

When this bio-char is added to soil, the carbon it contains is effectively removed from the atmospheric cycle. This makes pyrolysis a carbon-negative technology, meaning it can result in a net reduction of CO2 in the atmosphere.

Recovering Valuable Resources

For waste streams like plastics and tires, pyrolysis allows for the recovery of basic chemical building blocks. This reduces the need to extract and process virgin raw materials, conserving natural resources and saving energy.

Understanding the Trade-offs and Challenges

While powerful, pyrolysis is not a perfect solution. A clear-eyed, objective assessment requires acknowledging its operational challenges.

Significant Energy Input

The process is energy-intensive, as it requires maintaining very high temperatures. The overall efficiency and net energy gain depend heavily on using the syngas output to help power the system's own heat requirements.

Dependence on Feedstock Quality

The composition of the input material, or feedstock, directly impacts the quality and quantity of the outputs. Contaminants in the waste stream can disrupt the process or result in undesirable byproducts that require further management.

Complexity of Process Control

Achieving a specific, desired output (e.g., maximizing bio-oil production) requires precise control over temperature, pressure, and processing time. Pyrolysis is a sophisticated industrial process, not a simple disposal method.

Applying Pyrolysis to Strategic Goals

The decision to adopt pyrolysis technology is best made by aligning its capabilities with a primary strategic objective.

- If your primary focus is waste management: Pyrolysis offers a superior alternative to landfilling by dramatically reducing waste volume and converting it into stable, manageable products.

- If your primary focus is renewable energy production: The process provides a reliable pathway to convert diverse, locally sourced waste materials into consistent biofuels and syngas.

- If your primary focus is carbon reduction and sustainability: The creation of bio-char enables long-term carbon sequestration, making pyrolysis a key technology in the circular and bio-based economies.

Ultimately, we adopt pyrolysis because it fundamentally reframes our concept of "waste," treating it instead as a valuable, untapped resource for a more sustainable future.

Summary Table:

| Key Aspect | Description |

|---|---|

| Primary Goal | Transform low-value organic waste into high-value products |

| Main Products | Bio-oil (liquid fuel), Syngas (energy), Bio-char (carbon sequestration) |

| Key Benefits | Waste reduction, Renewable energy generation, Carbon-negative technology |

| Common Feedstocks | Biomass, plastics, tires, agricultural residues |

| Strategic Applications | Waste management, Energy production, Carbon reduction initiatives |

Ready to transform your waste streams into valuable resources? KINTEK specializes in advanced pyrolysis equipment and laboratory solutions that help you convert organic waste into biofuels, chemicals, and stable carbon products. Our expertise in thermochemical processing can help you achieve your sustainability goals while creating economic value. Contact our experts today to discuss how pyrolysis technology can benefit your specific laboratory or industrial application!

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What are the different types of pyrolysis machines? Choose the Right System for Your Output

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds