In Scanning Electron Microscopy (SEM), a sputter coater is used to apply an ultra-thin, electrically conductive layer onto non-conductive samples. This essential preparation step is what makes it possible to acquire clear, high-resolution images of materials like ceramics, polymers, and biological specimens, which would otherwise produce distorted and unusable results.

The core function of sputter coating is to solve a fundamental problem: the electron beam used by an SEM will accumulate on the surface of a non-conductive sample, causing a "charging" effect that catastrophically distorts the image. The conductive coating provides a path for this charge to dissipate to ground, enabling stable and accurate imaging.

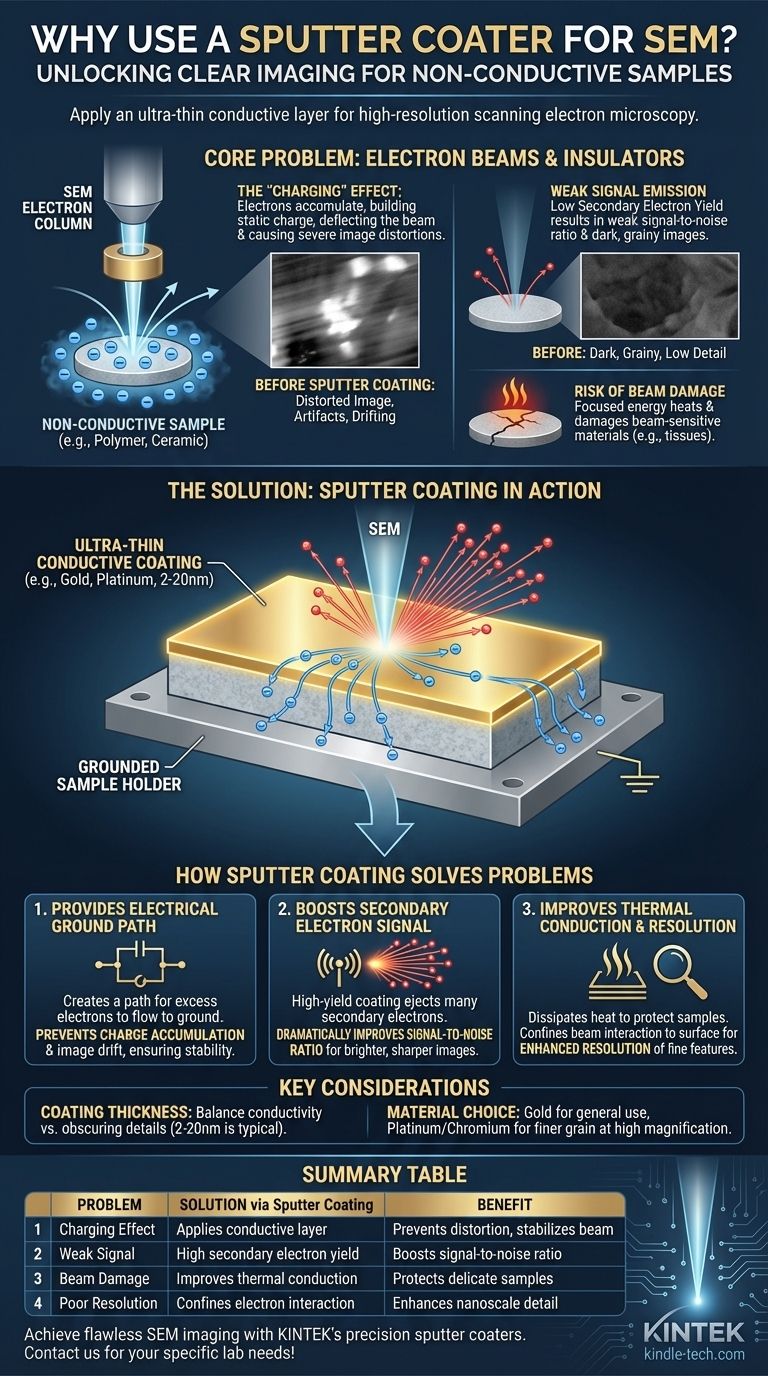

The Core Problem: Electron Beams and Insulators

To understand the need for sputter coating, you must first understand how an SEM interacts with a sample that cannot conduct electricity. This interaction creates several critical imaging issues.

The "Charging" Effect

When the SEM's primary electron beam strikes a non-conductive surface, those electrons have nowhere to go. They accumulate on the sample, building up a negative static charge.

This localized charge deflects the incoming electron beam, causing severe image artifacts. You will often see bright patches, distorted features, or a drifting image, making meaningful analysis impossible.

Weak Signal Emission

The image in an SEM is primarily generated by detecting secondary electrons that are ejected from the sample's surface by the primary beam.

Many non-conductive materials are inherently poor emitters of these secondary electrons. This results in a weak signal and a low signal-to-noise ratio, producing a dark, grainy, and indistinct image.

Risk of Beam Damage

The focused energy of the electron beam can heat and damage delicate or "beam-sensitive" samples. This is a significant concern for polymers, organic tissues, and other soft materials, which can be altered or destroyed by the microscope itself.

How Sputter Coating Solves These Problems

Applying a thin metal film, typically just 2-20 nanometers thick, directly counteracts each of these issues and dramatically improves image quality.

Providing an Electrical Ground Path

The most important benefit is that the conductive coating—often gold, platinum, or iridium—creates a path for the excess electrons to flow away from the imaged area and down to the grounded SEM sample holder.

This prevents charge accumulation entirely, stabilizing the image and eliminating the distortions common to non-conductive samples.

Boosting the Secondary Electron Signal

The metals used for sputter coating are chosen because they have a very high secondary electron yield. When the primary beam hits this coating, it ejects a large number of secondary electrons.

This flood of new signal dramatically improves the signal-to-noise ratio. The result is a much brighter, sharper, and more detailed image that reveals the true surface topography of the underlying specimen.

Improving Thermal Conduction and Resolution

The metal coating also helps to dissipate heat away from the analysis area, offering a layer of protection for beam-sensitive specimens.

Furthermore, the coating reduces the penetration depth of the primary electron beam. This confines the interaction to the very near-surface region, which can improve the resolution of fine surface features and edges.

Understanding the Trade-offs

While essential, the sputter coating process is not without its own considerations. Achieving the best results requires balancing competing factors.

Coating Thickness is Critical

The thickness of the sputtered layer is a crucial parameter. A layer that is too thin will not be fully conductive and will fail to prevent charging.

Conversely, a layer that is too thick will begin to obscure the fine nanoscale details of your sample's actual surface. The goal is to apply the thinnest possible continuous film that effectively dissipates charge.

The Choice of Material Matters

Different coating materials are used for different applications. Gold is a common and effective choice for general imaging due to its high conductivity and secondary electron yield.

However, other materials like gold/palladium, platinum, or chromium produce a finer grain structure in the coating, which is often necessary for achieving the highest magnifications without seeing the texture of the coating itself.

How to Apply This to Your Sample

Your decision to use a sputter coater should be based on the nature of your sample and your imaging goals.

- If your sample is a non-conductor (ceramic, polymer, glass, most biological tissue): Sputter coating is almost always required to prevent charging and acquire a usable image.

- If your sample is beam-sensitive: The conductive coating provides critical thermal and electrical protection that can prevent damage during analysis.

- If you need the highest possible image resolution: Even on poorly-conducting materials, a thin coating will significantly improve the signal-to-noise ratio, revealing fine surface details that would otherwise be lost in the noise.

Ultimately, sputter coating is a foundational technique that transforms an SEM from a tool for conductive materials into a universally powerful instrument for exploring the micro and nano-scale world of nearly any sample.

Summary Table:

| Problem | Solution via Sputter Coating | Benefit |

|---|---|---|

| Charging Effect | Applies conductive layer (e.g., Au, Pt) | Prevents image distortion, stabilizes beam |

| Weak Signal Emission | High secondary electron yield of metal coating | Boosts signal-to-noise ratio for sharper images |

| Beam Damage Risk | Improves thermal conduction | Protects delicate, beam-sensitive samples |

| Poor Resolution | Confines electron interaction to surface | Enhances detail visibility of nanoscale features |

Achieve flawless SEM imaging with KINTEK's precision sputter coaters. Whether you're working with ceramics, polymers, or biological samples, our lab equipment ensures optimal coating thickness and material selection to eliminate charging and maximize image clarity. Let our experts help you enhance your microscopy results—contact us today to discuss your specific laboratory needs!

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Benchtop Laboratory Vacuum Freeze Dryer

People Also Ask

- What machine is used to make lab-grown diamonds? Discover the HPHT & CVD Technologies

- What is the hot filament chemical vapour deposition of diamond? A Guide to Synthetic Diamond Coating

- What is the specific function of the metal filament in HF-CVD? Key Roles in Diamond Growth

- What is the role of the HF-CVD system in preparing BDD electrodes? Scalable Solutions for Boron-Doped Diamond Production

- How does PACVD equipment improve DLC coatings? Unlock Low Friction and High Heat Resistance