At its core, the controversy surrounding biochar is not about the material itself, but about the immense gap between its potential on a small scale and the risks of deploying it as a global climate solution. While biochar—a charcoal-like substance made by heating organic material in a low-oxygen environment—can provably improve soil and sequester carbon, the disagreements center on how it's made, where the raw materials come from, and whether its benefits can be realized at a massive scale without causing significant harm.

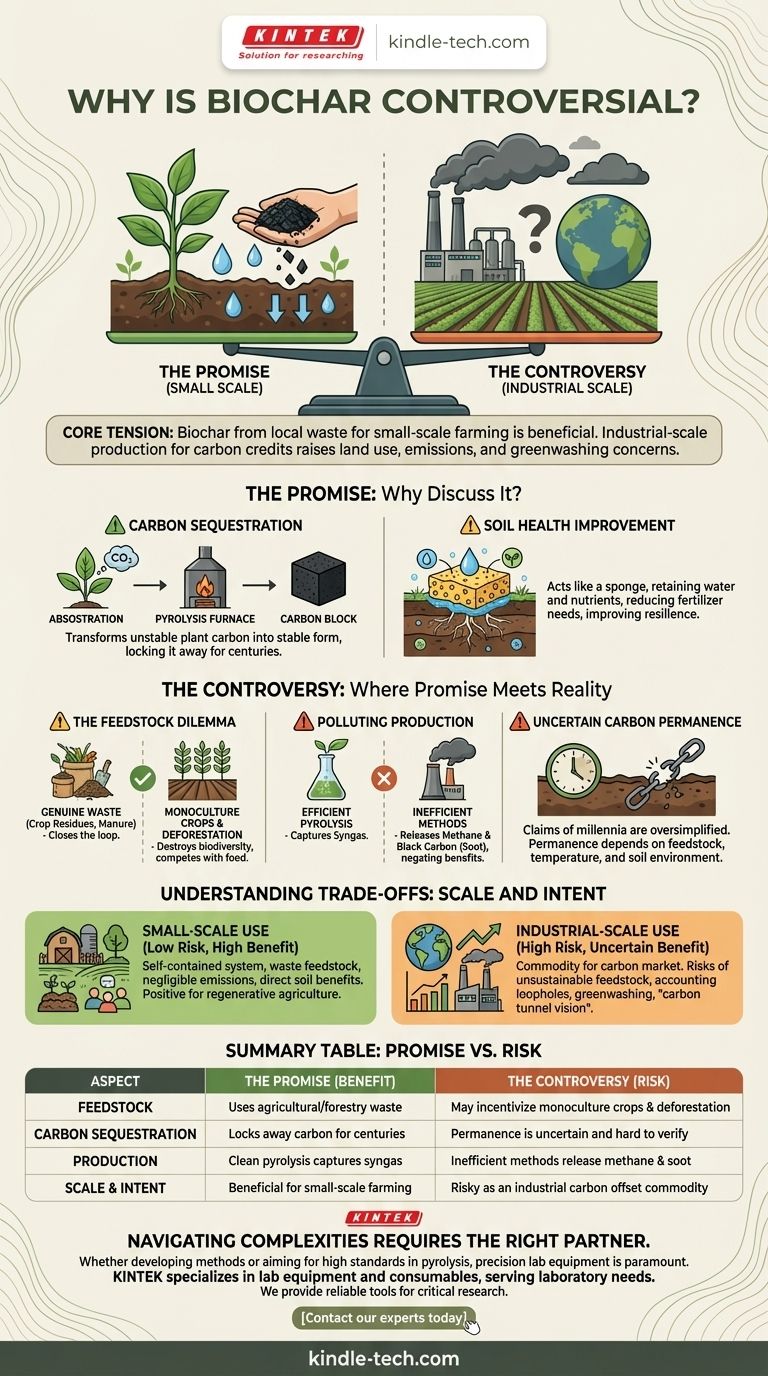

The central tension is this: Biochar produced from local waste for small-scale farming is widely seen as beneficial. The controversy ignites when discussing industrial-scale production for carbon credits, which raises serious concerns about land use, emissions, and its potential to distract from reducing fossil fuels.

The Promise: Why Is Biochar Discussed at All?

Before dissecting the controversy, it's crucial to understand why biochar is so appealing. Its proposed benefits are the foundation of the entire debate.

H3: Carbon Sequestration

The primary driver for global interest in biochar is its ability to act as a carbon sink. When plants grow, they draw CO2 from the atmosphere. When they decompose, that CO2 is released back.

The process of creating biochar, called pyrolysis, transforms this unstable plant carbon into a highly stable, solid form. When added to soil, this carbon can remain locked away for hundreds or even thousands of years, representing a form of carbon dioxide removal.

H3: Soil Health Improvement

For agriculture, biochar is prized as a powerful soil amendment. Its porous structure acts like a sponge, helping soil retain water and nutrients that would otherwise be washed away.

This can lead to reduced fertilizer needs, improved drought resistance, and a healthier soil microbiome. These benefits are most pronounced in degraded or poor-quality soils.

The Controversy: Where the Promise Meets Reality

The arguments against biochar arise when moving from the theoretical ideal to real-world implementation. The risks are not inherent to the substance but to the human and industrial systems used to create and deploy it.

H3: The Feedstock Dilemma

The single greatest point of contention is the source of the feedstock—the organic material used to make biochar.

- The Ideal: Using genuine waste products like crop residues, manure, or sustainably harvested forestry byproducts is the gold standard. This "closes the loop" on agricultural and forestry systems.

- The Risk: At a massive scale, demand could outstrip the supply of waste. This creates a dangerous incentive to clear forests or convert land to grow monoculture crops specifically for biochar production, destroying biodiversity and competing with food production.

H3: The Production Process Isn't Always Clean

Pyrolysis must be managed carefully. While high-tech industrial facilities can capture and use the gases released during production (syngas), less sophisticated or poorly managed methods can be highly polluting.

Inefficient pyrolysis can release methane (a potent greenhouse gas) and black carbon (soot), partially or entirely negating the climate benefits of the biochar produced.

H3: Carbon Permanence Is Not Guaranteed

Claims of carbon being locked away for millennia are an oversimplification. The actual permanence of biochar's carbon sequestration depends heavily on the feedstock used, the temperature of pyrolysis, and the soil environment it's placed in.

Some biochar may break down much faster than advertised, especially in certain climates or soil types. Verifying long-term permanence for the sake of carbon credits is a significant scientific and logistical challenge.

Understanding the Trade-offs: Scale and Intent

The biochar debate is fundamentally about context and scale. A solution that is beneficial in one context can become harmful in another.

H3: Small-Scale Use (Low Risk, High Benefit)

When a farmer uses crop residues from their own land to create biochar for their own fields, the system is self-contained.

The feedstock is demonstrably waste, the transport emissions are negligible, and the soil benefits are directly realized. In this context, biochar is almost universally seen as a positive tool for regenerative agriculture.

H3: Industrial-Scale Use (High Risk, Uncertain Benefit)

When biochar is produced as a commodity for the global carbon market, the incentives change. The goal shifts from improving a specific plot of land to maximizing the volume of carbon sequestered for sale.

This is where the risks of unsustainable feedstock sourcing, "carbon accounting" loopholes, and competition for land become acute. Critics argue this model could become a form of greenwashing, allowing corporations to offset emissions without making meaningful reductions at the source. It can also create "carbon tunnel vision," distracting from the primary goal of ending fossil fuel reliance.

Making the Right Choice for Your Goal

Navigating the biochar controversy requires understanding your objective. The right approach depends entirely on the problem you are trying to solve.

- If your primary focus is improving your farm or garden: Using biochar made from local, sustainable waste products is a low-risk and likely effective way to improve soil health and water retention.

- If your primary focus is evaluating carbon offsets for your organization: Scrutinize the biochar credit's entire lifecycle, demanding full transparency on feedstock origin, production methods, and third-party verification of carbon permanence.

- If your primary focus is developing global climate policy: Treat biochar as one potential tool among many, prioritizing direct emissions reductions first and applying strict sustainability criteria to any large-scale biochar production.

Ultimately, biochar is a tool, and like any tool, its value is determined by how, where, and why it is used.

Summary Table:

| Aspect | The Promise (Benefit) | The Controversy (Risk) |

|---|---|---|

| Feedstock | Uses agricultural/forestry waste | May incentivize monoculture crops & deforestation |

| Carbon Sequestration | Locks away carbon for centuries | Permanence is uncertain and hard to verify |

| Production | Clean pyrolysis captures syngas | Inefficient methods release methane & soot |

| Scale & Intent | Beneficial for small-scale farming | Risky as an industrial carbon offset commodity |

Navigating the complexities of sustainable materials requires the right partner and equipment.

Whether you are a researcher developing next-generation carbon sequestration methods or a producer aiming for the highest standards in pyrolysis, the quality and precision of your lab equipment are paramount.

KINTEK specializes in lab equipment and consumables, serving laboratory needs. We provide the reliable tools you need to conduct critical research and develop processes with confidence and accuracy.

Let's achieve your sustainability goals together. Contact our experts today to discuss how our solutions can support your work.

Visual Guide

Related Products

- Graphite Vacuum Continuous Graphitization Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vertical Laboratory Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

People Also Ask

- At what temperature does graphite thermal decompose? The Critical Role of Atmosphere

- What is the temperature resistance of graphite? Unlocking Its High-Temp Potential in Your Lab

- Is graphite good in high temperature? Unlocking Its Extreme Heat Potential

- What happens to graphite at high temperatures? Unlock its Extreme Heat Resistance

- What are the mechanical properties of graphite? Harnessing Rigidity and Managing Brittleness