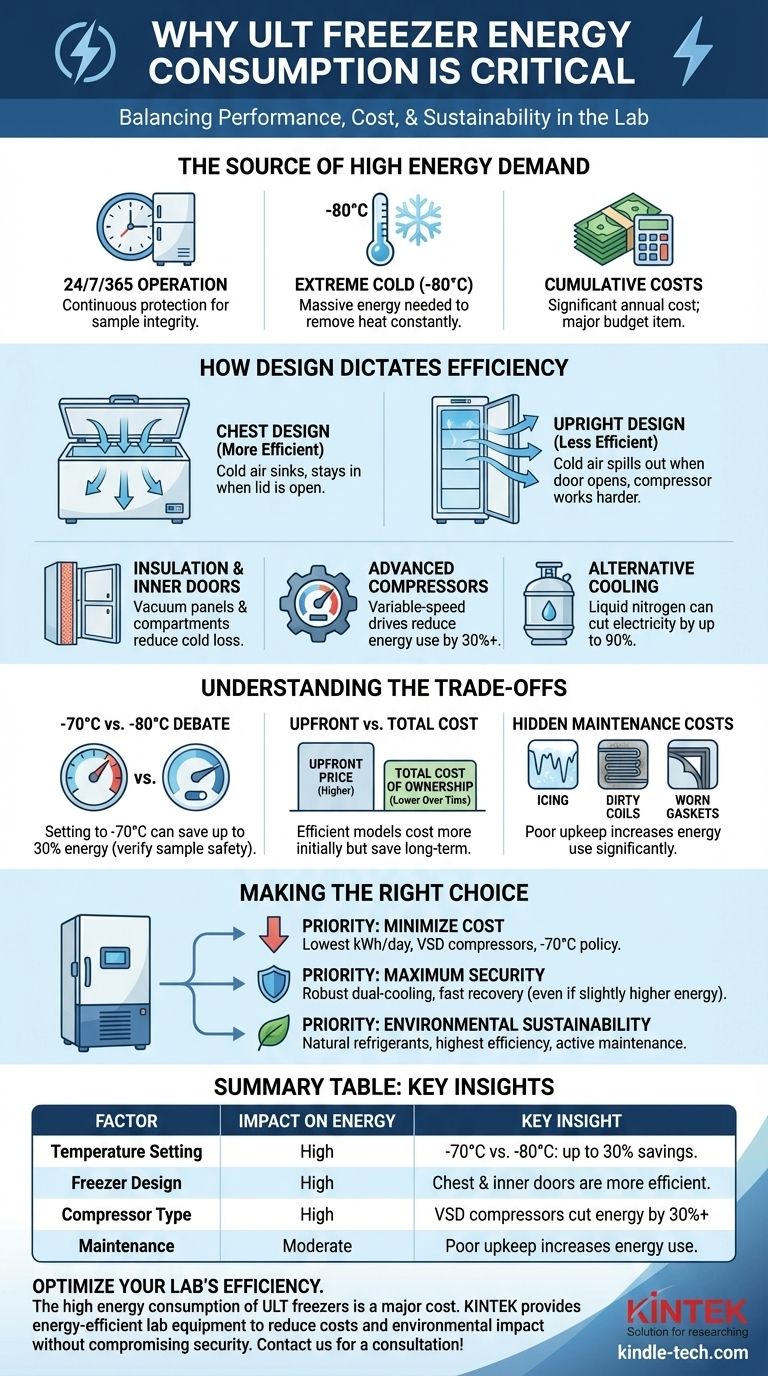

In short, energy consumption is a critical factor for Ultra-Low Temperature (ULT) freezers because they are among the most power-hungry devices in any laboratory. Operating 24/7 to maintain extreme temperatures like -80°C, a single ULT freezer can consume as much electricity as an average household. This constant, high-energy demand directly translates into significant operational costs and a substantial environmental footprint.

The core issue isn't just about the high energy use itself, but the tension between the non-negotiable need for sample preservation and the practical realities of budget and sustainability. Therefore, understanding energy consumption is key to balancing performance, cost, and environmental responsibility.

The Source of a ULT Freezer's High Energy Demand

ULT freezers are fundamentally different from household appliances. Their energy profile is defined by the extreme conditions they must consistently maintain to protect invaluable biological samples.

Constant, Uninterrupted Operation

A ULT freezer's primary mission is to ensure sample integrity, which requires it to run continuously without fail. Any shutdown or temperature fluctuation risks the loss of years of research. This 24/7/365 operation is the foundation of its high energy consumption.

The Physics of Extreme Cold

Maintaining a temperature of -70°C or -80°C in a room-temperature environment requires a massive and continuous removal of heat. The freezer's compressor system must work constantly to fight against ambient heat seeping in, making it an incredibly energy-intensive process.

The Cumulative Financial Impact

While a daily consumption figure like 8-10 kWh/day may seem abstract, it adds up quickly. Over a year, a single ULT freezer can incur electricity costs of $1,000 to $2,000 or more, depending on local energy rates. For an institution with dozens of freezers, this becomes a major line item in the operational budget.

How Freezer Design Dictates Energy Efficiency

Not all ULT freezers are created equal. Modern engineering has introduced significant improvements that directly impact energy usage, creating a clear distinction between older and newer models.

Chest vs. Upright Designs

The physical design has a direct impact on energy use. Chest freezers are inherently more efficient because cold air is dense and sinks. When you open the top lid, the cold air remains inside. In contrast, opening the door of an upright freezer causes the cold air to spill out, forcing the compressor to work hard to restore the temperature.

Insulation and Inner Doors

To combat heat infiltration, manufacturers use advanced vacuum-insulated panels and high-quality foam. Additionally, the inclusion of internal doors creates compartments within the freezer. This simple feature drastically reduces cold air loss when the main door is opened, minimizing the recovery time and energy needed.

Advanced Compressor Technology

A major evolution in ULT freezer design is the use of variable-speed drives (VSDs) for compressors. Instead of a simple on/off cycle, VSDs allow the compressor to run at lower speeds to maintain temperature, ramping up only when needed (like after a door opening). This technology alone can reduce energy consumption by 30% or more.

Alternative Cooling Systems

Some cutting-edge models are moving away from traditional compressor-based systems entirely. Technologies that use liquid nitrogen can reduce electricity consumption by up to 90%, offering a dramatic reduction in both operational cost and environmental impact, though they come with different logistical requirements.

Understanding the Trade-offs

Choosing or managing a ULT freezer involves balancing competing priorities. An energy-efficient choice is not always a straightforward one.

The -70°C vs. -80°C Debate

Many research protocols were written for -80°C out of tradition, not scientific necessity. Setting a freezer to -70°C instead of -80°C can reduce energy consumption by up to 30%. However, you must verify that this temperature is safe and appropriate for your specific samples before making the change.

Upfront Cost vs. Total Cost of Ownership

Highly energy-efficient freezers with modern features like VSD compressors often have a higher purchase price. However, their lower electricity usage can result in significant savings over the freezer's lifespan. Calculating the total cost of ownership—including both the initial price and years of energy costs—is essential for making a sound financial decision.

The Hidden Costs of Poor Maintenance

Energy efficiency is not just about the hardware; it's also about upkeep.

- Icing: Frost and ice buildup act as an insulator, forcing the freezer to work harder to cool the chamber. Regular defrosting is critical.

- Dirty Coils: Condenser coils clogged with dust cannot dissipate heat effectively, causing the compressor to run longer and hotter.

- Worn Gaskets: Damaged door seals allow warm, moist air to leak into the freezer, increasing both icing and energy consumption.

Making the Right Choice for Your Goal

Your priorities will determine the best approach to managing ULT freezer energy consumption.

- If your primary focus is minimizing operational cost: Prioritize models with the lowest kWh/day rating, variable-speed compressors, and implement a -70°C temperature policy where protocols allow.

- If your primary focus is maximum sample security: Look for models with robust dual-cooling systems and fast temperature recovery times, even if they have a slightly higher energy profile.

- If your primary focus is environmental sustainability: Choose freezers that use natural refrigerants and have the highest energy efficiency, and actively maintain them to ensure peak performance.

Ultimately, viewing energy consumption as a key performance indicator allows you to protect your research, your budget, and the environment simultaneously.

Summary Table:

| Factor | Impact on Energy Consumption | Key Insight |

|---|---|---|

| Temperature Setting | High | Setting to -70°C vs. -80°C can reduce energy use by up to 30%. |

| Freezer Design | High | Chest freezers and models with inner doors are inherently more efficient. |

| Compressor Type | High | Variable-speed drive (VSD) compressors can cut energy use by 30% or more. |

| Maintenance | Moderate | Poor upkeep (icing, dirty coils) forces the compressor to work harder, increasing energy use. |

Optimize your lab's energy efficiency and protect your valuable samples. The high energy consumption of ULT freezers is a major operational cost. KINTEK specializes in providing energy-efficient lab equipment and consumables, helping laboratories like yours reduce costs and environmental impact without compromising sample security. Let our experts help you select the right equipment for your specific needs. Contact us today for a consultation!

Visual Guide

Related Products

- 408L Advanced Vertical Laboratory Ultra Low Temperature Freezer for Critical Research Material Preservation

- 108L Vertical Ultra Low Temperature ULT Freezer

- 508L Advanced Vertical Ultra Low Temperature Freezer for Critical Laboratory Storage

- 708L Ultra Low Temperature Freezer High Performance Laboratory Freezer

- 208L Advanced Precision Laboratory Ultra Low Temperature Freezer for Cold Storage

People Also Ask

- What is the purpose of ultra-low temperature (ULT) freezers? Preserve Critical Biological Samples

- How does fast temperature recovery benefit ultra-low freezers? Protect Sample Integrity and Lab Efficiency

- How are advancements in compressor technology and refrigerant fluids improving ULT freezers? Boost Efficiency & Cut Costs

- What is the temperature control capability of ultra-low freezers? Precise Stability Down to -86°C

- What are ultra-low temperature freezers designed for? Preserving Your Most Valuable Biological Samples