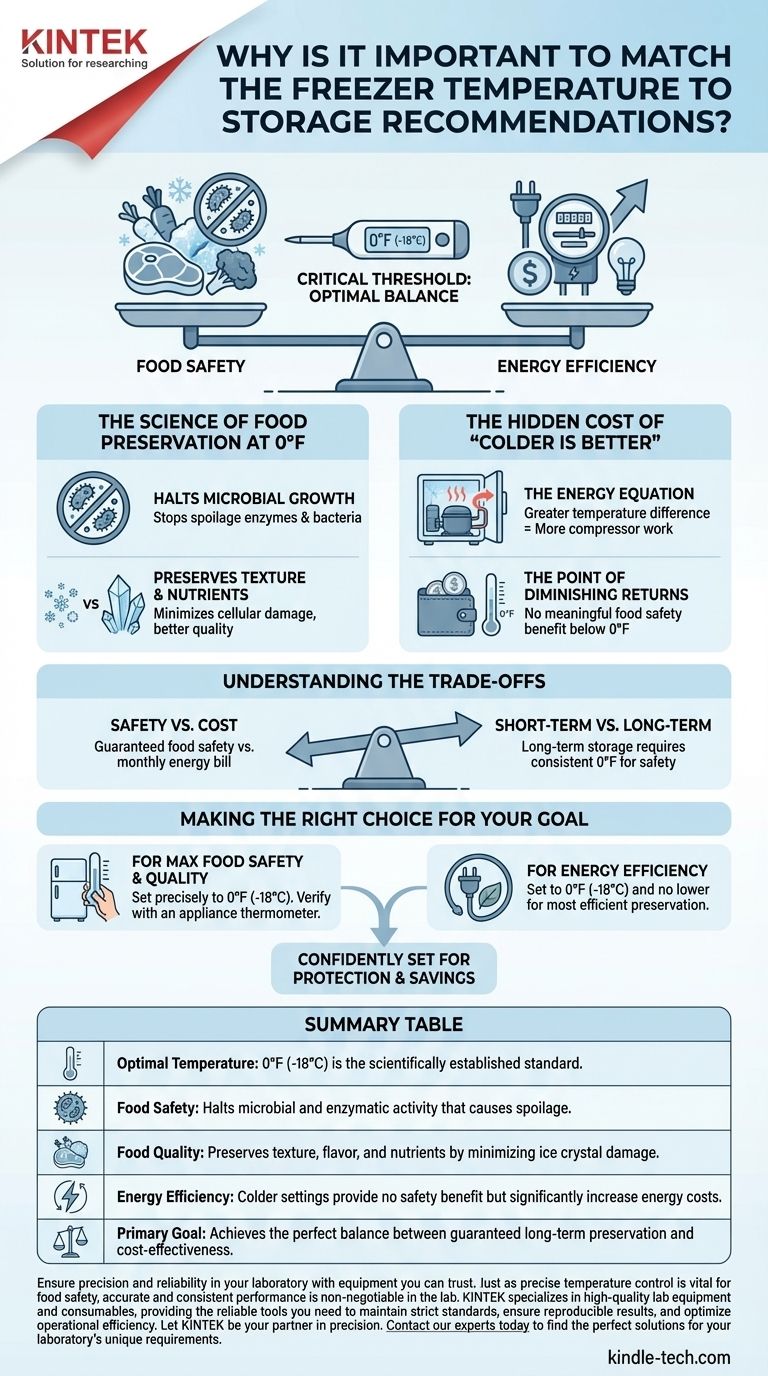

At its core, matching your freezer's temperature to storage recommendations is about finding the optimal balance between food safety and energy efficiency. The universally recommended temperature of 0°F (-18°C) is not an arbitrary number; it is the scientifically established point for safely preserving food for long periods without wasting electricity.

The central takeaway is that 0°F (-18°C) is the critical threshold where the enzymes and bacteria that cause food to spoil become inactive. Setting your freezer warmer than this risks food quality and safety, while setting it significantly colder provides no meaningful benefit and unnecessarily increases your energy costs.

The Science of Food Preservation at 0°F

The primary goal of a freezer is to stop the natural process of decay. Temperature is the single most important tool for achieving this, and the 0°F mark is the industry standard for a specific reason.

Halting Microbial Growth

Freezing does not sterilize food, but it does act like a pause button on the microorganisms (bacteria, yeasts, molds) that cause spoilage.

At 0°F (-18°C), microbial and enzymatic activity that degrades food quality and safety effectively stops. This is the key to safe, long-term storage.

Preserving Texture and Nutrients

A stable, low temperature also preserves the physical quality of your food.

Quickly freezing and storing items at 0°F creates smaller ice crystals. This minimizes damage to the food's cellular structure, better preserving its original texture, flavor, and nutritional value when thawed.

The Hidden Cost of "Colder is Better"

While keeping food safe is paramount, doing so efficiently impacts your budget. The relationship between freezer temperature and energy use is direct and significant.

The Energy Equation

Your freezer works by pumping heat from the inside to the outside. The greater the temperature difference between the freezer's interior and the surrounding room, the harder the compressor must work.

Lowering the setpoint from 0°F to -10°F can increase energy consumption by a noticeable amount for negligible improvement in food preservation.

The Point of Diminishing Returns

For the vast majority of household needs, temperatures below 0°F provide no practical food safety advantage.

You are paying more in electricity for a level of cold that your food simply does not require for safe, long-term storage.

Understanding the Trade-offs

The decision about your freezer's temperature is a constant balance between two opposing forces: absolute preservation and practical cost.

Safety vs. Cost

The fundamental trade-off is between guaranteed food safety and your monthly energy bill.

The 0°F (-18°C) standard represents the most effective compromise—the point where safety is assured without incurring excessive energy costs.

Short-Term vs. Long-Term Goals

If you only stored items for a few days, a slightly warmer temperature might not cause immediate spoilage.

However, freezers are designed for long-term preservation. The 0°F standard ensures that food you store for months remains just as safe as food you store for a week.

Making the Right Choice for Your Goal

To apply this knowledge effectively, align your freezer's setting with your primary objective.

- If your primary focus is maximum food safety and quality: Set your freezer precisely to 0°F (-18°C) and use an appliance thermometer to verify it, as built-in dials can be inaccurate.

- If your primary focus is energy efficiency: Ensure your freezer is set to 0°F (-18°C) and no lower, as this is the most energy-efficient temperature that guarantees long-term food preservation.

By understanding the principle behind the recommendation, you can confidently set your freezer to protect both your food and your finances.

Summary Table:

| Aspect | Key Insight |

|---|---|

| Optimal Temperature | 0°F (-18°C) is the scientifically established standard. |

| Food Safety | Halts microbial and enzymatic activity that causes spoilage. |

| Food Quality | Preserves texture, flavor, and nutrients by minimizing ice crystal damage. |

| Energy Efficiency | Colder settings provide no safety benefit but significantly increase energy costs. |

| Primary Goal | Achieves the perfect balance between guaranteed long-term preservation and cost-effectiveness. |

Ensure precision and reliability in your laboratory with equipment you can trust.

Just as precise temperature control is vital for food safety, accurate and consistent performance is non-negotiable in the lab. KINTEK specializes in high-quality lab equipment and consumables, providing the reliable tools you need to maintain strict standards, ensure reproducible results, and optimize operational efficiency.

Let KINTEK be your partner in precision. Contact our experts today to find the perfect solutions for your laboratory's unique requirements.

Visual Guide

Related Products

- 58L Precision Laboratory Ultra Low Temperature Upright Freezer for Critical Sample Storage

- 938L Vertical Ultra Low Temperature Freezer for Advanced Laboratory Storage

- 408L Advanced Vertical Laboratory Ultra Low Temperature Freezer for Critical Research Material Preservation

- 508L Advanced Vertical Ultra Low Temperature Freezer for Critical Laboratory Storage

- 158L Precision Vertical Ultra Low Freezer for Laboratory Applications

People Also Ask

- How does fast temperature recovery benefit ultra-low freezers? Protect Sample Integrity and Lab Efficiency

- What is the role of an ultra-low temperature (ULT) freezer in the freeze-thaw synthesis of hydrogel nanocomposites?

- What are the recommendations for storing mRNA vaccines in ultra-low temperature freezers? Ensure Absolute Stability at -80°C

- How do ultra-low temperature freezers achieve such low temperatures? The Science Behind -80°C Cooling

- What are ultra-low temperature freezers designed for? Preserving Your Most Valuable Biological Samples