In short, pyrolysis is gaining significant interest because it uniquely addresses several of our most pressing environmental and economic challenges simultaneously. It offers a powerful method to convert low-value waste streams—like mixed plastics, agricultural residues, and old tires—into high-value products such as fuels, chemicals, and soil amendments, directly aligning with the global push for a circular economy and decarbonization.

While the fundamental process of pyrolysis has been known for centuries, its modern resurgence is driven by its unique ability to chemically recycle materials that traditional methods cannot handle, transforming waste liabilities into valuable assets for a more sustainable future.

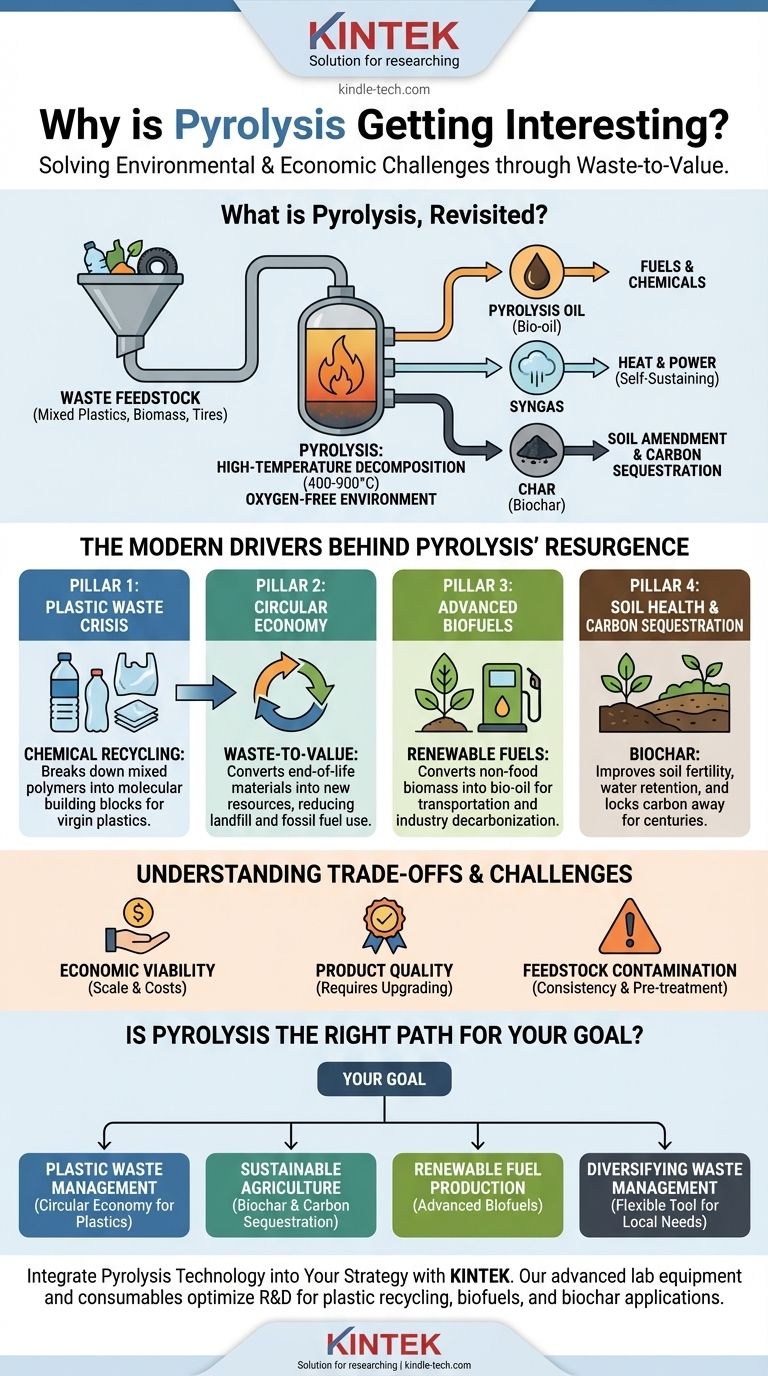

What is Pyrolysis, Revisited?

To understand its current relevance, it's crucial to be clear on what pyrolysis is and, just as importantly, what it is not.

The Core Process: Heating Without Oxygen

At its heart, pyrolysis is the thermal decomposition of materials at high temperatures in an oxygen-free environment. Think of it as a form of high-temperature "pressure cooking" rather than burning.

Because there is no oxygen, the material does not combust. Instead, the complex hydrocarbon molecules break down into smaller, simpler, and more valuable molecules.

This fundamental difference distinguishes it from incineration, which is simply burning waste to produce heat, and gasification, which involves partial oxidation to create syngas.

The Key Outputs: A Versatile Product Slate

The process breaks down a single waste input into three distinct and potentially valuable product streams:

- Pyrolysis Oil (Bio-oil): A liquid fuel similar to crude oil that can be upgraded into transportation fuels (like gasoline and diesel) or used as a feedstock for producing new chemicals and plastics.

- Syngas: A mixture of flammable gases (primarily hydrogen and carbon monoxide) that can be used on-site to generate the heat and power needed to run the pyrolysis plant, making the process more self-sustaining.

- Char (Biochar): A solid, carbon-rich material similar to charcoal. When produced from biomass, this biochar is a valuable soil amendment that improves water retention and agricultural yields while sequestering carbon in the ground for centuries.

The Modern Drivers Behind Pyrolysis's Resurgence

Pyrolysis isn't a new discovery, but a convergence of global trends has pushed it to the forefront of environmental technology.

The Mounting Plastic Waste Crisis

Mechanical recycling is effective for clean, single-stream plastics like PET bottles and HDPE jugs. However, it cannot handle the vast majority of plastic waste: mixed polymers, contaminated films, and multi-layer packaging.

Pyrolysis offers a chemical recycling solution. It can take these otherwise non-recyclable plastics and break them back down into their molecular building blocks, creating a liquid feedstock that can be used to manufacture virgin-quality plastics, closing the loop.

The Push for a Circular Economy

The traditional linear economic model of "take, make, dispose" is unsustainable. A circular economy aims to eliminate waste by keeping materials in use.

Pyrolysis is a cornerstone technology for this vision. It exemplifies a "waste-to-value" pathway, converting materials at the end of their life into new resources, reducing landfill dependence, and decreasing the need for virgin fossil fuels.

The Demand for Advanced Biofuels

As the world seeks to decarbonize transportation and industry, there is intense demand for renewable fuels. Pyrolysis can convert non-food biomass, such as wood waste, corn stover, and other agricultural residues, into a liquid bio-oil.

While this oil requires significant upgrading to become a "drop-in" fuel, it represents a viable pathway to producing advanced biofuels that do not compete with food crops for land.

Soil Health and Carbon Sequestration

The production of biochar from agricultural or forestry waste is another powerful driver. When added to soil, biochar improves its structure, fertility, and ability to hold water, reducing the need for irrigation and fertilizer.

Crucially, the carbon in biochar is extremely stable. This means that applying biochar to soil effectively locks away carbon that would have otherwise been released into the atmosphere, making it a key carbon sequestration technology.

Understanding the Trade-offs and Challenges

Despite its immense potential, pyrolysis is not a silver bullet. A clear-eyed, objective view requires acknowledging its technical and economic hurdles.

Economic Viability and Scale

The profitability of a pyrolysis plant is highly sensitive to three factors: the cost of the feedstock (waste), the operational cost of the plant, and the market price for the end products. Scaling these operations from pilot projects to large, industrial facilities remains a significant financial and engineering challenge.

Technical Hurdles in Product Quality

The raw pyrolysis oil produced is often acidic, corrosive, and chemically unstable. It contains high levels of oxygen and water, meaning it cannot be directly used in conventional refineries or engines. It requires a costly and energy-intensive upgrading process to become a viable commercial product.

Feedstock Contamination and Consistency

The process is highly dependent on the quality and consistency of the incoming waste. Contaminants common in municipal solid waste, such as chlorine from PVC plastics or heavy metals, can poison catalysts, damage equipment, and create hazardous byproducts that require careful management.

Is Pyrolysis the Right Path for Your Goal?

The applicability of pyrolysis depends entirely on the specific problem you are trying to solve.

- If your primary focus is plastic waste management: Pyrolysis is one of the most promising technologies for creating a circular economy for plastics, especially for mixed and low-grade streams.

- If your primary focus is sustainable agriculture: Slow pyrolysis for biochar production is a mature and proven method to improve soil health and achieve verifiable carbon sequestration.

- If your primary focus is renewable fuel production: Fast pyrolysis of biomass is a key pathway, but you must be prepared to invest in the significant downstream processing required to upgrade the bio-oil.

- If your primary focus is diversifying waste management: Pyrolysis offers a flexible tool that can complement existing recycling and energy recovery efforts, but it demands a robust business case based on local feedstock availability and product markets.

By understanding its specific applications and acknowledging its challenges, pyrolysis stands as a critical technology for building a more circular and sustainable economy.

Summary Table:

| Key Driver | Pyrolysis Solution | Primary Output |

|---|---|---|

| Plastic Waste Crisis | Chemical recycling of mixed plastics | Pyrolysis Oil (for new plastics/fuels) |

| Circular Economy Demand | Converts waste into valuable resources | Syngas, Bio-oil, Biochar |

| Advanced Biofuel Needs | Processes non-food biomass | Upgradable Bio-oil |

| Soil Health & Carbon Sequestration | Produces stable carbon-rich char | Biochar (soil amendment) |

Ready to integrate pyrolysis technology into your sustainability strategy? KINTEK specializes in advanced lab equipment and consumables for pyrolysis research and development. Whether you're exploring plastic recycling, biofuel production, or biochar applications, our precise heating systems and analytical tools help you optimize your process. Contact our experts today to discuss how KINTEK can support your laboratory's contribution to a circular economy.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Non Consumable Vacuum Arc Induction Melting Furnace

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

People Also Ask

- How is pyrolysis useful in waste management? Transform Waste into Energy and Valuable Products

- Why is pyrolysis better than gasification? For Versatile, Storable Bio-Products

- What are the benefits of pyrolysis? Turn Waste into Valuable Resources and Energy

- What are the benefits of calcination process? Achieve Precise Material Transformation for Your Industrial Needs

- Is there a market for pyrolysis oil? A Guide to Opportunities and Challenges

- What is the problem with pyrolysis oil? Key Challenges of Bio-Oil as a Fuel

- What is the best catalyst for plastic pyrolysis? Match Your Catalyst to Your Plastic Waste Goals

- What are the steps of biomass pyrolysis? Turn Waste into Biochar, Bio-Oil & Biogas