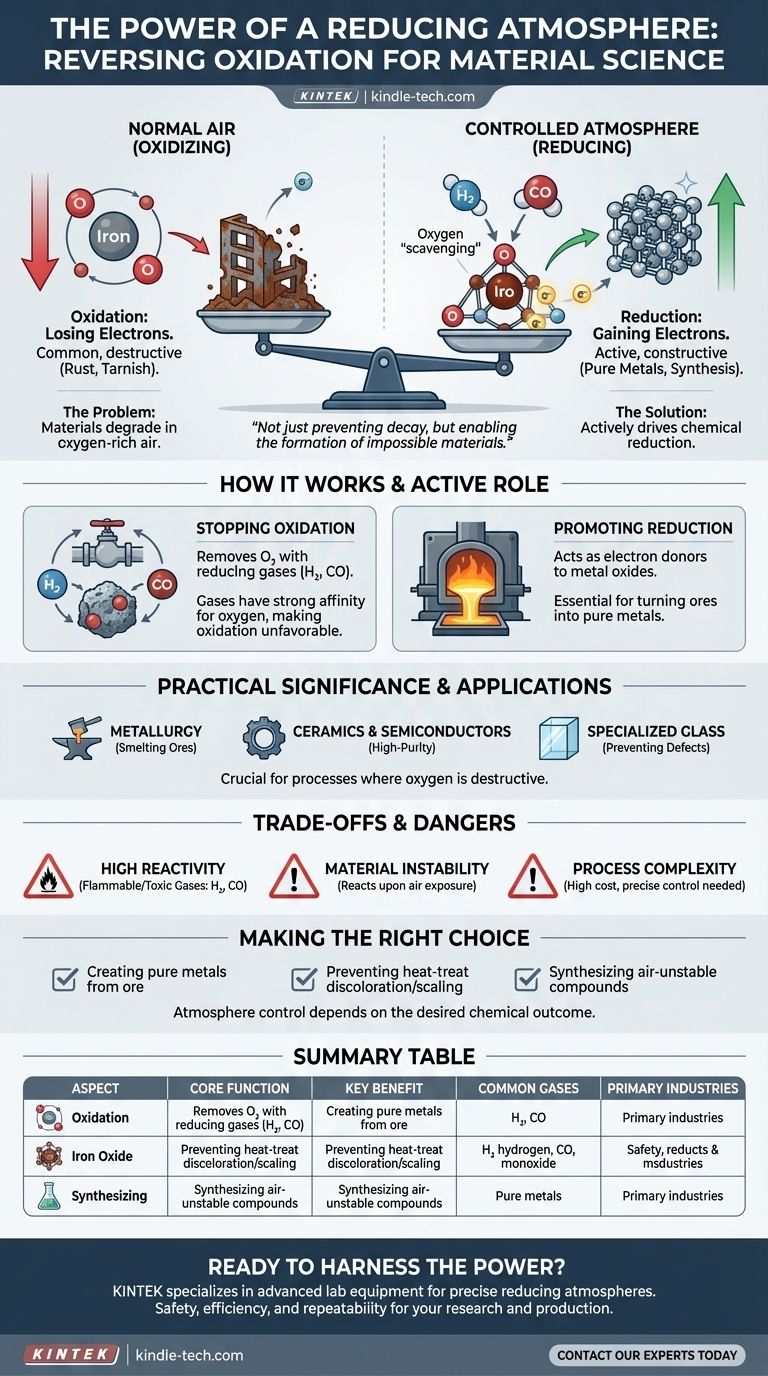

A reducing atmosphere is significant because it fundamentally reverses the common process of oxidation. Instead of allowing materials to rust, tarnish, or burn by reacting with oxygen, this oxygen-poor environment actively promotes chemical reduction, a critical process for creating pure metals and specific chemical compounds.

The true significance of a reducing atmosphere lies in its ability to actively drive chemical reactions in a direction opposite to what occurs in our normal, oxygen-rich air. It's not just about preventing decay like rust; it's about enabling the formation of materials that would otherwise be impossible to create.

The Core Principle: Preventing Oxidation

Oxidation is one of the most common chemical reactions, but in many industrial and scientific processes, it is a destructive force that must be eliminated.

What is Oxidation?

Oxidation is a chemical process where a substance loses electrons. While it can happen with other elements, this reaction most famously involves oxygen, which is highly reactive.

The most intuitive example of oxidation is rust. When iron is exposed to oxygen and water, it oxidizes, forming iron oxide and losing its structural integrity.

How a Reducing Atmosphere Stops Oxidation

A reducing atmosphere directly counteracts this process by removing oxygen and often introducing specific reducing gases, such as hydrogen (H₂) or carbon monoxide (CO).

These gases have a strong affinity for oxygen atoms, effectively scavenging any that are present and creating an environment where oxidation reactions are chemically unfavorable.

The Active Role: Promoting Reduction

A reducing atmosphere is not merely passive; it is an active chemical environment that facilitates the opposite of oxidation.

Understanding Chemical Reduction

Reduction is the process where an atom gains electrons, lowering its oxidation state. In this environment, the reducing gases act as electron donors.

This process is essential for turning metal ores, which are often metal oxides, back into their pure metallic forms.

Practical Significance in Industry

In metallurgy, furnaces are filled with a reducing atmosphere to smelt ore. For example, carbon monoxide is used to strip oxygen atoms from iron ore (iron oxide), leaving behind pure, molten iron.

This principle is also critical in manufacturing high-purity ceramics, semiconductors, and specialized glass, where even minimal oxidation would ruin the final product's properties.

Understanding the Trade-offs and Dangers

While powerful, creating and working with a reducing atmosphere presents significant challenges and requires precise control.

High Reactivity and Hazards

The gases used to create a reducing atmosphere—such as hydrogen and carbon monoxide—are often highly flammable, explosive, or toxic. Handling them requires specialized equipment and stringent safety protocols.

Material Instability

Materials synthesized or treated in a reducing environment may be perfectly stable within that atmosphere but can become highly unstable or reactive once exposed to normal, oxygen-rich air.

Process Complexity and Cost

Maintaining a specific gaseous composition, especially at high temperatures in an industrial furnace, is a complex engineering challenge. This adds significant cost and operational complexity compared to processes that can be run in open air.

Making the Right Choice for Your Goal

Controlling an atmosphere is a tool, and its use depends entirely on the desired chemical outcome.

- If your primary focus is creating pure metals from ore: A reducing atmosphere is not just beneficial; it is the fundamental requirement for the smelting process.

- If your primary focus is preventing heat-treat discoloration or scaling on metal: A reducing or inert atmosphere is necessary to protect the surface finish and material properties.

- If your primary focus is synthesizing compounds that are unstable in air: A controlled reducing atmosphere enables chemical reactions that would otherwise fail immediately due to oxidation.

Ultimately, mastering the shift from an oxidizing to a reducing environment provides precise control over chemical destiny, allowing us to forge materials and uncover processes impossible in the world outside the lab.

Summary Table:

| Aspect | Significance of a Reducing Atmosphere |

|---|---|

| Core Function | Reverses oxidation by removing oxygen and promoting chemical reduction. |

| Key Benefit | Enables the production of pure metals from ores and protects materials from tarnishing. |

| Common Gases Used | Hydrogen (H₂), Carbon Monoxide (CO). |

| Primary Industries | Metallurgy, Ceramics, Semiconductor, and Specialized Glass Manufacturing. |

| Main Challenge | Requires handling of flammable/explosive gases and precise environmental control. |

Ready to harness the power of a controlled atmosphere in your lab?

At KINTEK, we specialize in providing the advanced lab equipment and consumables you need to create and manage precise reducing atmospheres for your research and production. Whether you are smelting metals, developing high-purity ceramics, or synthesizing air-sensitive compounds, our solutions ensure safety, efficiency, and repeatability.

Let KINTEK empower your material science breakthroughs. Contact our experts today to discuss your specific laboratory requirements!

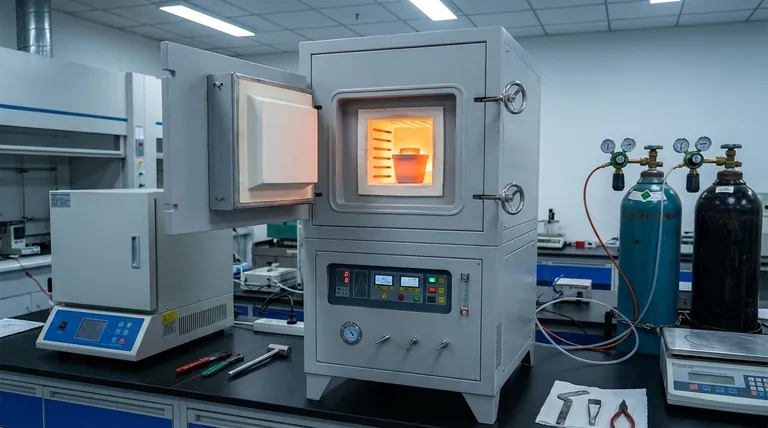

Visual Guide

Related Products

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Controlled Nitrogen Inert Hydrogen Atmosphere Furnace

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

People Also Ask

- What is meant by inert atmosphere? A Guide to Preventing Oxidation & Ensuring Safety

- Why nitrogen is used in furnace? A Cost-Effective Shield for High-Temperature Processes

- What provides an inert atmosphere? Achieve Safety and Purity with Nitrogen, Argon, or CO2

- How do you make an inert atmosphere? Master Safe, Pure Processes with Inerting

- Can nitrogen gas be heated? Leverage Inert Heat for Precision and Safety