Choosing the right location for your ULT freezer is as critical as choosing the freezer itself. The placement of this high-performance equipment directly impacts its energy consumption, the long-term integrity of your samples, and the overall efficiency and safety of your daily lab operations. A poorly placed freezer will cost more to run, wear out faster, and create logistical bottlenecks.

A ULT freezer is not a simple appliance; it's an active heat-exchange machine. Its location dictates how effectively it can shed heat, which in turn governs its performance, energy use, and reliability. Proper placement is about balancing the freezer's operational needs with the lab's workflow.

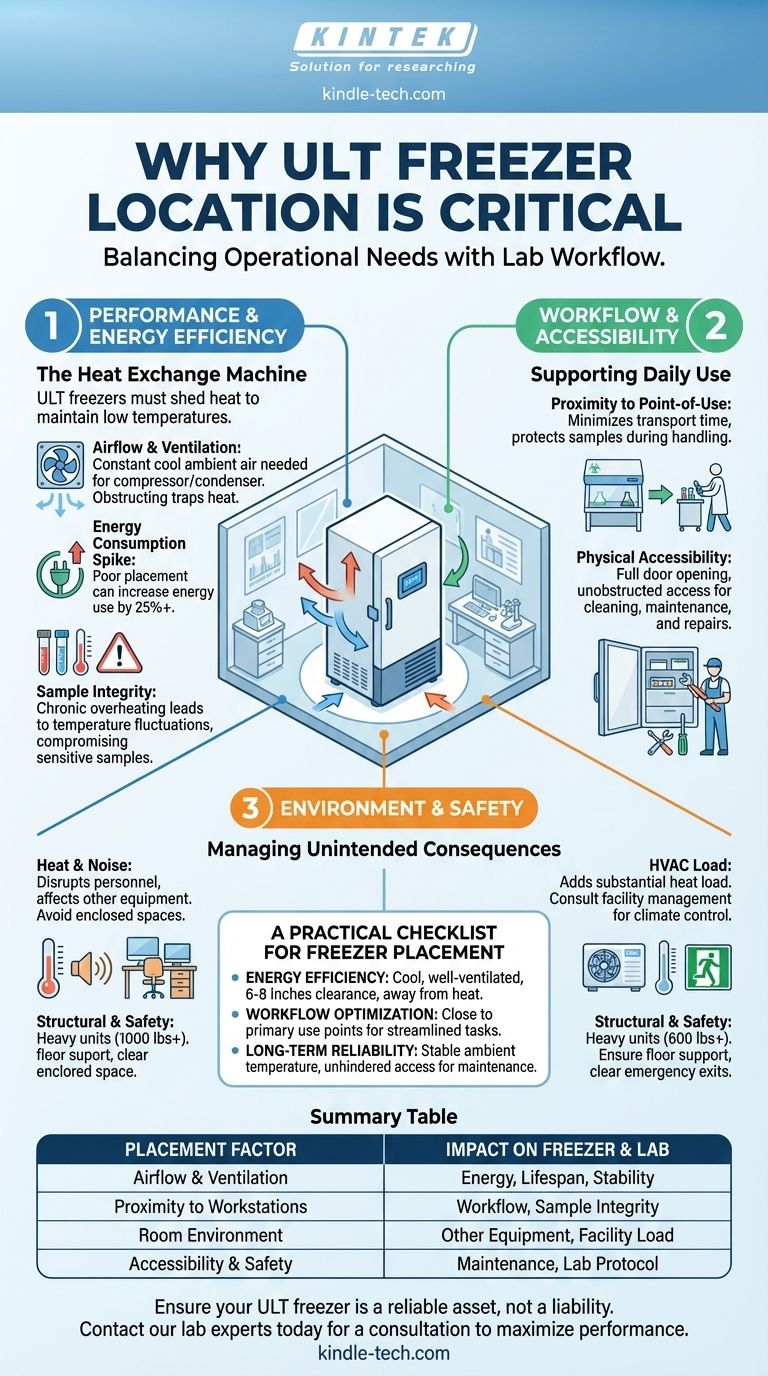

The Critical Link Between Location and Performance

The most immediate impact of a freezer’s location is on its core mechanical function: maintaining an ultra-low temperature. This is entirely dependent on its ability to manage heat.

The Importance of Airflow and Heat Dissipation

A ULT freezer works by pulling heat out of its interior chamber and releasing it into the surrounding room via its compressor and condenser coils.

For this process to be efficient, the freezer requires a constant supply of cool, ambient air flowing over these components. Obstructing this airflow traps heat around the unit.

This forces the compressor to run longer and work harder to achieve its target temperature, leading to premature wear on critical parts.

Impact on Energy Consumption

When the compressor works harder due to poor ventilation, it draws significantly more power.

A freezer tucked into a tight alcove or placed too close to a wall can see its energy consumption spike by 25% or more. Over the lifespan of the unit, this translates into substantial and unnecessary operational costs.

Protecting Sample Integrity

An overworked cooling system is an unreliable one. Chronic overheating can lead to difficulty in maintaining a stable setpoint, causing temperature fluctuations inside the chamber.

These deviations, even if small, can compromise the long-term viability of sensitive biological samples, jeopardizing years of research.

Integrating the Freezer into Your Lab Workflow

Beyond mechanical performance, the freezer's location must support the people who use it every day. A poorly integrated freezer becomes a constant source of inefficiency.

Proximity to Point-of-Use

For time-sensitive protocols, every second a sample spends outside of the freezer matters.

Placing the freezer near the relevant workstations—such as a biosafety cabinet or a sample processing bench—minimizes transport time and reduces the risk of sample degradation.

Ensuring Physical Accessibility

Consider the practical realities of using the freezer. Users must be able to open the door fully without blocking a major walkway.

Technicians also need unobstructed access to the back and sides of the unit for routine cleaning, preventative maintenance, and emergency repairs.

Understanding the Trade-offs and Environment

A ULT freezer actively changes the environment around it. Failing to account for this can lead to unintended consequences for your facility and other equipment.

Managing Heat and Noise

ULT freezers generate significant heat and noise. Placing one in a small, enclosed office or near sensitive analytical instruments can be a major mistake.

The constant noise can be disruptive to personnel, and the exhausted heat can raise the ambient room temperature, potentially affecting the performance of other equipment.

HVAC Load and Room Temperature

The heat output of a ULT freezer adds a substantial load to the room's HVAC system. A room with multiple freezers requires robust climate control to prevent the ambient temperature from rising.

Consulting with facilities management before installation is crucial to ensure the existing HVAC can handle the additional heat load.

Structural and Safety Considerations

These units are extremely heavy, often weighing over 600 lbs (270 kg). You must confirm that the floor is rated to support the weight, especially on upper levels.

Furthermore, the freezer must never obstruct an emergency exit path or create a trip hazard. Its placement is a key component of lab safety planning.

A Practical Checklist for Freezer Placement

Use these guidelines to evaluate potential locations and make a decision that aligns with your laboratory's priorities.

- If your primary focus is energy efficiency: Prioritize placement in a cool, well-ventilated area with ample clearance (at least 6-8 inches) on all sides, away from direct sunlight or other heat-generating equipment.

- If your primary focus is workflow optimization: Place the freezer as close as is safely possible to the primary point of use to streamline daily tasks and protect sample integrity during handling.

- If your primary focus is long-term reliability: Ensure the location has a stable ambient temperature and provides clear, unhindered access for routine maintenance and potential emergency servicing.

A well-placed freezer is a foundational element of a reliable, efficient, and safe laboratory environment.

Summary Table:

| Placement Factor | Impact on Freezer & Lab |

|---|---|

| Airflow & Ventilation | Affects energy consumption, compressor lifespan, and temperature stability. |

| Proximity to Workstations | Influences workflow efficiency and sample integrity during handling. |

| Room Environment (HVAC, Heat) | Determines impact on other equipment and overall facility load. |

| Accessibility & Safety | Crucial for maintenance, servicing, and adherence to lab safety protocols. |

Ensure your lab's ULT freezer is a reliable asset, not a liability.

The right placement is key to protecting your valuable samples and optimizing your lab's workflow. KINTEK specializes in laboratory equipment and consumables, offering expert guidance to help you select and position the perfect ULT freezer for your specific needs.

Contact our lab experts today for a consultation to maximize the performance and longevity of your critical storage equipment.

Visual Guide

Related Products

- 108L Vertical Ultra Low Temperature ULT Freezer

- 508L Advanced Vertical Ultra Low Temperature Freezer for Critical Laboratory Storage

- 708L Ultra Low Temperature Freezer High Performance Laboratory Freezer

- 208L Advanced Precision Laboratory Ultra Low Temperature Freezer for Cold Storage

- 608L Essential Laboratory Ultra Low Temperature Freezer For Critical Sample Preservation

People Also Ask

- How are advancements in compressor technology and refrigerant fluids improving ULT freezers? Boost Efficiency & Cut Costs

- What are ultra-low temperature freezers designed for? Preserving Your Most Valuable Biological Samples

- What temperature ranges are typically associated with ultra-low temperature freezers? Preserve Samples from -40°C to -86°C

- Why are ULT freezers considered vital equipment in labs? Ensuring Uncompromised Sample Integrity for Critical Research

- How is temperature controlled in ultra low temperature freezers? A Guide to Stable -80°C Storage