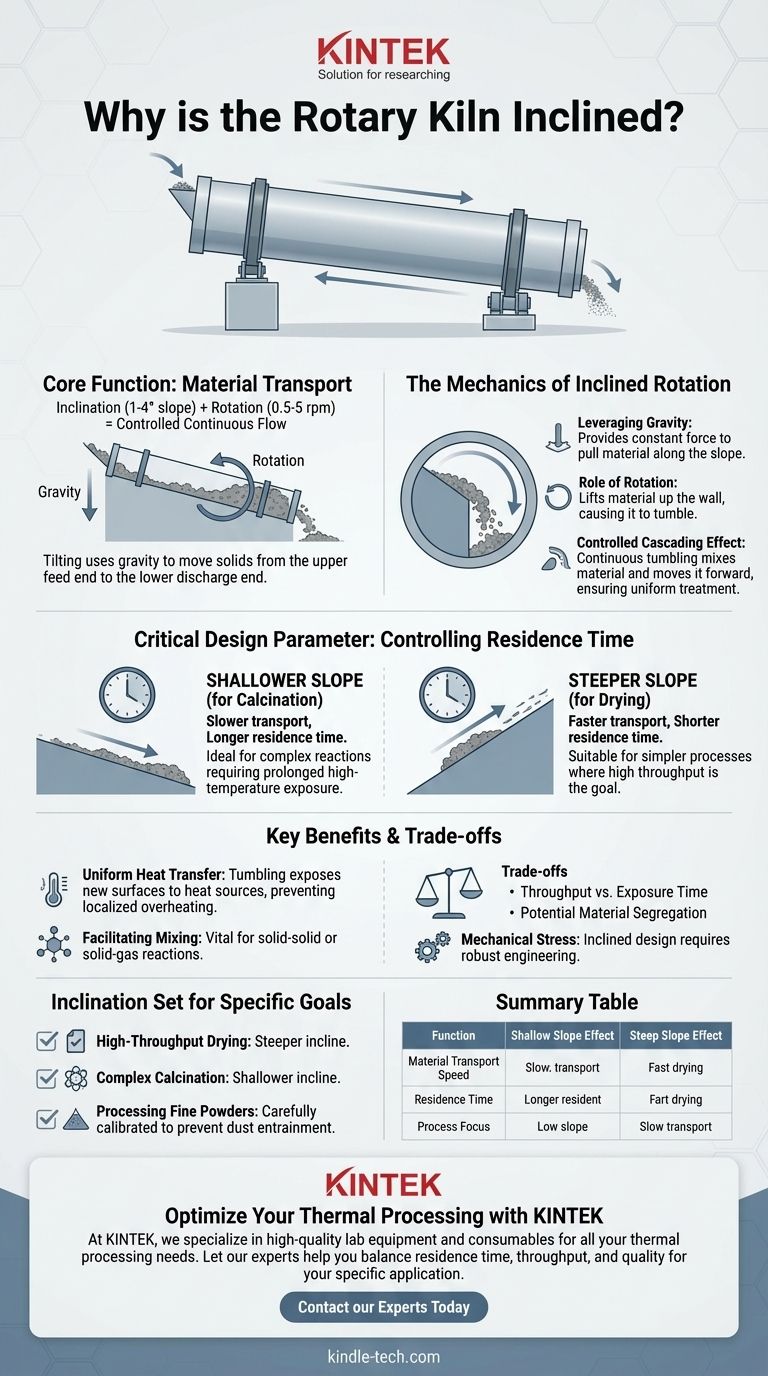

At its core, a rotary kiln's inclination is the primary mechanism for material transport. By tilting the cylindrical shell, typically at a slope of 1 to 4 degrees, the system uses gravity to move solids continuously from the upper feed end to the lower discharge end. This simple design principle is fundamental to its entire operation as a continuous processing unit.

The kiln's slope, combined with its rotation, is not just for transport; it is a sophisticated control system. This combination dictates the material's residence time, mixing efficiency, and heat exposure—the critical variables for achieving a desired chemical or physical transformation.

The Mechanics of Inclined Rotation

A rotary kiln's effectiveness comes from the interplay between its slope and its slow rotation. These two factors work in concert to create a controlled environment for material processing.

Leveraging Gravity for Continuous Flow

The kiln is mounted on rollers at a slight angle to the horizontal. This inclination provides the gentle but constant gravitational force needed to pull material along its length. Without this slope, the material would simply tumble in place.

The Role of Rotation

As the kiln rotates slowly (typically 0.5 to 5 revolutions per minute), it lifts the material up the interior wall. Gravity then causes the material to tumble or cascade back down towards the bottom of the kiln.

Creating a Controlled "Cascading" Effect

This combined action of rotation and gravity creates a continuous tumbling motion. The material is constantly mixed and turned over on itself while simultaneously moving forward down the slope. This ensures every particle follows a similar path and receives similar treatment.

Why Inclination is a Critical Design Parameter

The specific angle of inclination is not arbitrary; it is a carefully engineered variable that directly influences the kiln's performance and the final product's quality.

Controlling Residence Time

Residence time is the average duration a particle spends inside the kiln. The steepness of the incline is the primary control for this variable.

A shallower slope results in slower material transport, increasing the residence time. This is crucial for complex chemical reactions, like calcination, that require prolonged exposure to high temperatures.

A steeper slope speeds up material flow, reducing residence time. This is suitable for simpler processes like drying or basic heating where high throughput is the main goal.

Ensuring Uniform Heat Transfer

The references note the importance of even heat transmission, often from 360° heater placement. The cascading motion caused by rotation constantly exposes new surfaces of the material bed to this heat.

This prevents localized overheating and ensures that the heat is distributed uniformly throughout the material, which is essential for consistent product quality. The inclination ensures this process happens continuously along the entire length of the kiln.

Facilitating Mixing and Reactions

The tumbling action is a form of dynamic mixing. For processes involving reactions between different types of solids or between a solid and a gas, this constant agitation is vital. It improves contact between reactants and promotes a more complete and efficient chemical conversion.

Understanding the Trade-offs

While essential, the kiln's inclination introduces design and operational compromises that must be managed.

The Balance Between Throughput and Exposure

The most significant trade-off is between processing speed and reaction completeness. Increasing the slope to boost throughput may reduce residence time to the point where the material is discharged before the desired physical or chemical change is finished.

Potential for Material Segregation

In a mixture of particles with different sizes or densities, the tumbling action can sometimes lead to segregation. Finer or denser particles may move at a different rate than coarser or lighter ones, potentially leading to a non-uniform product at the discharge end.

Mechanical Stress and Wear

An inclined, rotating design places immense structural load on the support rollers, bearings, and drive systems. This requires robust engineering and regular maintenance to manage wear and prevent mechanical failure, especially given the high-temperature operating environment.

How Inclination is Set for a Specific Goal

The optimal inclination is not a universal value; it is engineered specifically for the material being processed and the desired outcome. The choice reflects a deliberate balance between chemical requirements and operational efficiency.

- If your primary focus is high-throughput drying: A steeper incline is often chosen to move material through the kiln quickly, maximizing output.

- If your primary focus is a complex chemical reaction (calcination): A shallower incline is selected to increase residence time, ensuring the reaction proceeds to completion.

- If your primary focus is processing fine or lightweight powders: The inclination and rotation speed are carefully calibrated to ensure uniform flow without excessive dust being carried out by the process gas.

Ultimately, the kiln's incline transforms a simple rotating tube into a precise and continuous industrial reactor.

Summary Table:

| Function | Effect of a Shallow Slope | Effect of a Steep Slope |

|---|---|---|

| Material Transport Speed | Slower | Faster |

| Residence Time | Longer (Ideal for calcination) | Shorter (Ideal for drying) |

| Process Focus | Complex chemical reactions | High-throughput heating/drying |

Optimize Your Thermal Processing with KINTEK

Understanding the critical role of kiln inclination is just the first step. Whether you are drying, calcining, or processing fine powders, the right equipment is key to achieving uniform results and maximum efficiency.

At KINTEK, we specialize in high-quality lab equipment and consumables for all your thermal processing needs. Our expertise can help you select the right system to perfectly balance residence time, throughput, and product quality for your specific application.

Contact our experts today to discuss how we can support your laboratory's goals and enhance your processes.

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

People Also Ask

- What are the zones in rotary kiln in cement production? Master the Core Process for High-Quality Clinker

- What is the difference between calcining and roasting? A Guide to High-Temperature Processing

- What is the principle of rotary kiln? Mastering Continuous Thermal Processing

- What biomass is used in pyrolysis? Selecting the Optimal Feedstock for Your Goals

- What equipment is used in pyrolysis? Choosing the Right Reactor for Your Feedstock and Products