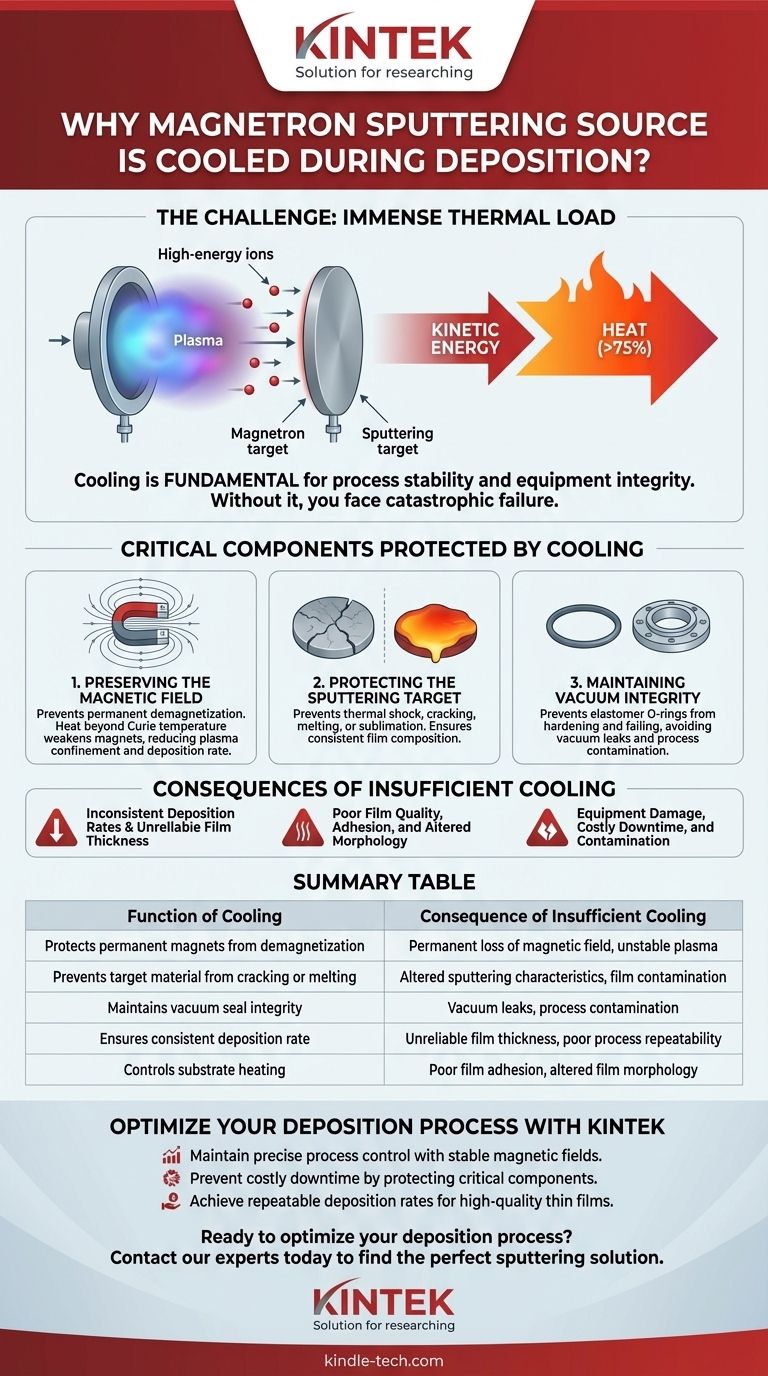

The cooling of a magnetron sputtering source is not optional; it is a fundamental requirement for process stability and equipment integrity. During deposition, the target material is bombarded by high-energy ions from the plasma. A significant portion of this kinetic energy—often over 75%—is converted directly into heat on the target's surface. Active cooling is the primary mechanism for dissipating this intense thermal load and preventing catastrophic failure.

The core reason for cooling is to manage the immense and unavoidable waste heat generated by ion bombardment. Without it, you would permanently damage the magnets, crack the target material, and lose control over the entire deposition process, rendering your results inconsistent and unreliable.

The Physics of Heat Generation

To understand the need for cooling, you must first understand where the heat originates. The entire process is driven by transferring energy from an electrical power supply into the plasma and onto the target material.

The Role of Ion Bombardment

A magnetron sputtering source uses a combination of electric and magnetic fields to create and confine a dense plasma near the face of the sputtering target. Positively charged ions (typically argon) from this plasma are accelerated by a strong negative voltage on the target.

Upon impact, each ion's kinetic energy is transferred to the target. While some of this energy ejects a target atom (the sputtering process), the vast majority simply causes atoms in the target lattice to vibrate, which is the definition of heat.

Power Input vs. Thermal Load

The total amount of heat generated is directly proportional to the electrical power delivered to the source. Running a process at higher power to achieve a faster deposition rate means more ions are striking the target per second, generating a greater thermal load that must be removed by the cooling system.

Critical Components Protected by Cooling

The active cooling system, typically a closed-loop water circuit, is designed to protect several critical components whose performance degrades rapidly with temperature.

Preserving the Magnetic Field

This is arguably the most important function of cooling. Most modern magnetrons use powerful rare-earth permanent magnets (like Neodymium Iron Boron, NdFeB) to confine the plasma. These magnets have a maximum operating temperature, known as the Curie temperature, beyond which they begin to lose their magnetic strength permanently.

Even well below the Curie point, elevated temperatures will cause a temporary, and eventually permanent, reduction in the magnetic field. A weaker field results in less efficient plasma confinement, leading to a lower sputtering rate and a completely different deposition uniformity profile.

Protecting the Sputtering Target

The target material itself is vulnerable to thermal damage. Brittle ceramic targets can easily crack due to thermal shock if they are not cooled effectively. Metallic targets can melt, sublimate, or undergo phase changes and recrystallization, which alters their sputtering characteristics and can change the composition of your deposited film.

Maintaining Vacuum Integrity

The magnetron source is mounted to the vacuum chamber with flanges that are sealed by elastomer O-rings. If the body of the magnetron becomes too hot, this heat will conduct to the flange and "bake" the O-ring. This causes the elastomer to become hard and brittle, compromising its ability to hold a seal and leading to vacuum leaks that will contaminate your process.

The Consequences of Insufficient Cooling

Failing to provide adequate cooling is not a minor process deviation; it has severe and compounding consequences for your equipment and your results.

Inconsistent Deposition Rates

As an uncooled or poorly cooled source heats up, its magnetic field will weaken. This causes the plasma density to drop and the deposition rate to drift downwards throughout a run. This makes it impossible to achieve a specific film thickness repeatably, especially during long depositions.

Poor Film Quality and Adhesion

A hot target radiates a significant amount of heat directly onto the substrate. This unwanted heating can cause stress, change the film's crystal structure (morphology), and lead to poor adhesion. The properties of the film you create at the beginning of the run will be different from the one at the end.

Equipment Damage and Downtime

The ultimate consequence is equipment failure. A permanently demagnetized magnet array requires a costly and time-consuming replacement of the entire source. A cracked target can throw particles that contaminate the chamber, and a failed vacuum seal can shut down operations for days.

Optimizing Cooling for Your Deposition Process

Proper cooling is a prerequisite for success, and its management can be tuned to your specific objectives. By monitoring the temperature and flow rate of your coolant, you gain a powerful lever for process control.

- If your primary focus is process stability and repeatability: Ensure your coolant flow rate and temperature are constant and monitored throughout the entire deposition to guarantee a stable magnetic field and target temperature.

- If your primary focus is achieving high deposition rates: Recognize that higher power requires more aggressive cooling, so you must use a chiller and flow rate sufficient to handle the increased thermal load.

- If your primary focus is sputtering thermally sensitive materials: Use robust cooling on the source to minimize the radiative heat transferred from the target to your substrate, thereby protecting the integrity of both the target and the film.

By mastering the thermal management of your sputtering source, you gain direct control over the quality, reliability, and consistency of your thin-film deposition results.

Summary Table:

| Function of Cooling | Consequence of Insufficient Cooling |

|---|---|

| Protects permanent magnets from demagnetization | Permanent loss of magnetic field, unstable plasma |

| Prevents target material from cracking or melting | Altered sputtering characteristics, film contamination |

| Maintains vacuum seal integrity | Vacuum leaks, process contamination |

| Ensures consistent deposition rate | Unreliable film thickness, poor process repeatability |

| Controls substrate heating | Poor film adhesion, altered film morphology |

Achieve stable, high-quality thin films with reliable sputtering equipment from KINTEK.

Proper thermal management is non-negotiable for consistent results in magnetron sputtering. KINTEK specializes in high-performance lab equipment, including sputtering systems designed with robust cooling solutions to protect your investment and ensure process integrity.

Our systems help you:

- Maintain precise process control with stable magnetic fields and target temperatures.

- Prevent costly downtime by protecting critical components from thermal damage.

- Achieve repeatable deposition rates for consistent, high-quality thin films.

Ready to optimize your deposition process? Contact our experts today to find the perfect sputtering solution for your laboratory's specific needs.

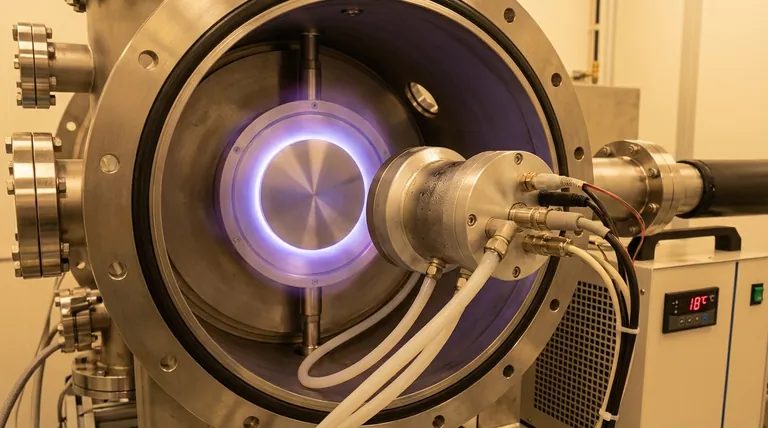

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Three-dimensional electromagnetic sieving instrument

- Vacuum Cold Trap Direct Cold Trap Chiller

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- How thick is gold sputtering? Achieve Precise Coatings from Ångstroms to Microns

- What are the problems associated with biomass production? Key Environmental and Economic Hurdles

- How does a DC magnetron sputtering work? A Guide to High-Speed, Uniform Thin Films

- What is the difference between pyrolysis and decomposition? Unlock the Power of Controlled Thermal Processing

- What are the risks associated with the sintering process? Key Strategies to Prevent Failure & Maximize Quality

- What are the disadvantages of plate and frame filter press? High Labor Costs and Inefficient Batch Processing

- How long does fast pyrolysis take? Achieve High Bio-Oil Yields in Under 2 Seconds

- What are the advantages of pyrolysis? Turn Waste into Renewable Fuels and Biochar