Introduction to Rotary Kilns

Rotary kilns stand as versatile industrial instruments, igniting chemical reactions or physical shifts through the power of heat. Industries spanning from carbon product manufacturing to industrial sintering benefit greatly from their applications. These cylindrical marvels offer a pivotal role in sustainable forest waste utilization within carbon product manufacturing. Moreover, they play a significant part in industrial sintering processes, essential for the production of diverse industrial goods. Let's delve deeper into the heart of rotary kilns, understanding their mechanisms, applications, and how they drive efficiency across various sectors.

Applications of Rotary Kilns

Rotary kilns play a pivotal role in various industrial processes, including the production of carbon products and industrial sintering. Here's a closer look at their applications:

Carbon Product Manufacturing

Rotary kilns are instrumental in producing a wide range of carbon products, especially as the demand for sustainable solutions grows. Key products include:

-

Biochar: Produced from organic cellulosic feeds like manure, crop residues, and coconut husks, biochar offers a sustainable avenue for utilizing forest product wastes.

-

Activated Carbon: Rotary kilns are preferred for producing activated carbon due to their efficiency and scalability. Both mature and nascent applications utilize rotary kilns for manufacturing activated carbon.

-

Carbon Black Recovery: Rotary kilns are increasingly used to recover carbon black from waste tires via pyrolysis, contributing to waste management and resource recovery efforts.

Industrial Sintering Processes

In industrial settings, rotary kilns are essential for sintering various materials, such as dolomite and magnesite, and for calcining limestone, gypsum, and bauxite. Other applications include:

-

Ore Roasting: Rotary kilns are employed for roasting a wide variety of ores, supporting mineral processing operations.

-

Sponge Iron Production: Rotary kilns aid in reducing ores, crucial in sponge iron production.

-

Waste Management: Kilns play a vital role in incinerating waste materials, desorbing soil contaminants, and upgrading phosphate ores.

Other Applications

Beyond carbon product manufacturing and sintering processes, rotary kilns find use in diverse applications, including:

-

Plastics and Ceramics Processing: Rotary kilns facilitate plastics processing, ceramics production, and activated coal regeneration.

-

Tyre Recycling: Kilns contribute to scrap tire recycling efforts by converting waste tires into valuable products.

-

Sewage Sludge and Waste Wood Recycling: Rotary kilns are utilized for sewage sludge disposal and waste wood recycling, promoting sustainability.

Versatility and Innovation

Rotary kilns demonstrate remarkable versatility, serving as both a building material equipment for cement production and a rotary dryer for moisture removal. Kiln shells are designed to withstand high temperatures and structural stresses, ensuring operational efficiency and longevity.

As industries seek more efficient and sustainable processes, rotary kilns continue to evolve and find new applications. Ongoing experimental work and research drive innovation, shaping the future of thermal processing technologies.

Types of Rotary Furnaces

Rotary tube furnaces play a crucial role in advanced materials processing, offering a versatile and efficient means of heat treatment. These furnaces are integral to various industrial processes, providing precise temperature control and uniform heating. Let's delve into the main types of rotary furnaces and their functionalities.

Rotary tube furnaces, such as indirect-fired models, operate as continuous thermal systems, employing multiple thermal control zones to apply heat to the incoming process material. This is achieved through the transfer of heat from a heat source, which can be powered by gas or electricity, to a rotating tube containing the process materials and atmospheres. The heat then transfers from the tube wall to the bed of material being processed.

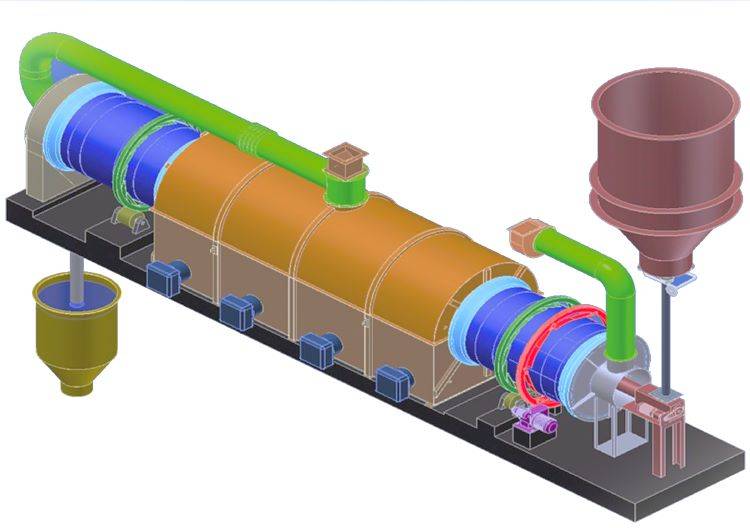

Working Principle

A rotary furnace, shaped like a barrel, rotates around its axis during heat treatment. This rotation facilitates the transfer of the sample from one end of the barrel to the other. Additionally, the slight tilt of the furnace allows for smooth sample movement. As the furnace rotates, hot gases pass through the chamber, facilitating the heat treatment process. Depending on the application requirements, the hot gases can flow in the opposite direction or the same direction as the sample.

Advantages of Rotary Tube Furnaces

Rotary tube furnaces offer several advantages:

-

Versatility: These furnaces can burn pulverized, solid, gaseous, or liquid fuel directly in the working section, allowing for efficient heating of various types of materials.

-

Uniform Heating: The design of rotary tube furnaces ensures uniform heating of materials, leading to consistent processing results.

-

Physiochemical Processing: These furnaces are specifically designed to heat loose materials for physiochemical processing, making them suitable for a wide range of industrial applications.

-

Classification: Rotary tube furnaces are classified based on their method of heat exchange (parallel or opposing gas flow) and their energy transfer method (direct, indirect, or combined), providing flexibility in application.

Types of Rotary Furnaces

The main types of rotary furnaces include those where different types of fuel are burned directly in the working section, with heating gases flowing towards the material to be processed. These furnaces feature a metal drum lined with refractory, mounted at a slight angle to the horizontal on supporting rollers. The diameter of the drum may vary along its length, and it is rotated by an electric motor through a reduction gear and transmission system.

Dimensions and Output Capacity

Rotary furnaces vary widely in dimensions, with lengths ranging from 50 to 230 meters and diameters from 3 to 7.5 meters. The output capacity of a rotary furnace can be substantial, reaching up to 150 tons per hour of processed product. There is a growing trend towards integrating rotary furnaces with various heat exchange equipment to enhance efficiency, economy, and size reduction.

In conclusion, rotary tube furnaces are indispensable tools for advanced materials processing, offering precise temperature control, uniform heating, and versatility in application. Their diverse functionalities make them essential components in various industrial processes, contributing to enhanced efficiency and product quality.

Working Principles of Rotary Kilns

Rotary kilns rely on rotary drum technology to process materials. Material is tumbled in a rotating drum, which is heated either internally (direct heating) or externally (indirect heating) to heat the material to the desired temperature and cause the intended reaction. The temperature(s) at which the material is processed, as well as the retention time (how long the material is processed) are predetermined based on a thorough chemical and thermal analysis. The rotating drum is sealed to the stationary breeching at each end to control the atmosphere and temperature inside the kiln to manage the reaction(s).

Operating at temperatures ranging from 800 to 2,200°F, rotary kilns, sometimes referred to as calciners, are widely used to carry out several basic thermal processes, including:

- Drying: Removing moisture from materials.

- Heating: Raising the temperature of materials to facilitate chemical reactions.

- Chemical Reactions: Triggering chemical transformations within materials.

During its passage along the kiln, the bed material undergoes different transformations. A typical sequence of processes taking place in long kilns includes drying, heating, and chemical reactions which cover a broad range of temperatures. The most common configuration is counter-current flow, whereby the bed and gas flows are in opposite directions, although co-current flow can be utilized in some instances, for example, rotary driers.

Advantages of Rotary Kilns

Simple Operation and Adoption

Rotary drum technology is employed in nearly every industry imaginable. With simple operating principles, the machines require minimal operator training and supervision. In many cases, operators are already familiar with how the machines work because of their extensive use in other settings, making adoption simple and straightforward.

Longevity

The rotary kiln’s simple mechanics, combined with its robust build, equate not only to a reliable system but also to a system that will stand the test of time. When properly maintained, rotary kilns can provide decades of consistent processing.

Working Principle of Rotary Kiln

The Rotary Kiln is made up of gas flow, fuel combustion, heat transfer, and material movement. It ensures complete combustion of fuel, transferring the heat effectively to the material. As the material receives the heat, it undergoes a series of physical and chemical changes, eventually forming the finished clinker.

Rotary Kiln Maintenance

Maintenance of rotary kilns is crucial to ensure optimal performance and longevity. Regular inspections, lubrication, and cleaning are essential to prevent breakdowns and maintain efficiency. Additionally, addressing any issues promptly can prevent costly repairs and downtime.

Overall, understanding the working principles of rotary kilns and implementing proper maintenance procedures are key to maximizing their efficiency and lifespan.

Laboratory Furnaces: Considerations and Types

Laboratory furnaces play a crucial role in various scientific and industrial processes, offering precise control over temperature and conditions. When selecting a laboratory furnace, several key considerations must be taken into account to ensure optimal performance and safety.

Key Considerations

-

Process Temperature: Determine the required temperature range for your applications, considering both maximum and minimum temperatures. Different furnace types offer varying temperature capabilities, from standard heating to ultra-high temperature applications.

-

Control Requirements: Assess the level of control needed for your processes, including temperature stability, uniformity across the chamber, and programmable settings. Advanced control features enhance efficiency and reproducibility.

-

Chamber Dimensions: Evaluate the internal dimensions of the furnace chamber to accommodate your sample sizes comfortably. Consider the volume and shape of samples to ensure even heating and efficient utilization of space.

Types of Laboratory Furnaces

Muffle Furnaces

- Ideal for high-temperature applications such as ignition tests, heat treating steel parts, and gravimetric analysis.

- Offer precise temperature control and uniform heating, suitable for various research and industrial processes.

Ashing Furnaces

- Designed for determining ash content in materials such as distillate fuels, crude oils, lubricating oils, and waxes.

- Provide controlled combustion environments for accurate ashing processes and residue analysis.

Tube Furnaces

- Commonly used in educational, governmental, and industrial laboratories for purification and synthesis processes.

- Offer uniform heating along the length of the tube, suitable for continuous processing and controlled reactions.

Safety Features

- Self-Diagnostic Functions: Ensure mechanical stability and safety with features like sensor error detection, automatic overheat prevention, and main relay failure disconnection.

- Safety Mechanisms: Look for models with key lock functions, earth leakage breakers, and auto-recovery after power failures to prevent accidents and ensure operational reliability.

Customization Options

- Exhaust System: Essential for thermal processes to control gas emissions and maintain a controlled environment.

- Gas Loading Devices: Add N2 gas loading devices with flow meters for controlled atmosphere applications.

- Communication and Control: Incorporate external communication adapters, terminals for temperature and alarm outputs, and event tracking features for process monitoring and control.

Customizing your laboratory furnace to specific requirements enhances its functionality and ensures optimal performance in research, testing, and production environments.

Conclusion

Pyrolysis furnaces serve as indispensable assets in various industries, offering versatile solutions for waste management, chemical production, and scientific research. Understanding the diverse applications and types of pyrolysis reactors underscores their significance in promoting sustainability and resource efficiency across different sectors.

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

Related Articles

- Electric Rotary Kiln Pyrolysis Furnace: Design, Operation, and Applications

- Mastering Rotary Kilns: A Comprehensive Guide to Operation, Applications, and Maintenance

- Electric Rotary Kiln Pyrolysis Furnace: A Comprehensive Guide to Pyrolysis Technology

- Exploring Rotary Tube Furnaces: A Comprehensive Guide

- Optimizing Industrial Processes: Rotary Kiln and Laboratory Furnace Solutions