Optical Properties of Diamond

Transmittance and Refractive Index

Diamond stands out as a superior material for optical windows, particularly due to its exceptional transmittance and refractive index across multiple spectral bands. This unique characteristic makes diamond an ideal choice for applications requiring precise optical performance.

Transmittance

Diamond's high transmittance is particularly notable in the ultraviolet (UV), far-infrared (FIR), and microwave regions. In the UV range, diamond can transmit wavelengths as short as 225 nanometers, making it invaluable for spectroscopic analysis and high-energy physics experiments. In the FIR and microwave bands, diamond's transmittance remains remarkably stable, enabling its use in advanced imaging systems and communication technologies.

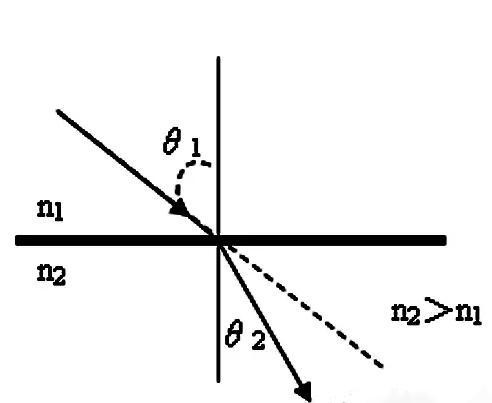

Refractive Index

The refractive index of diamond is another critical factor that enhances its optical utility. Diamond's refractive index is approximately 2.42, which is significantly higher than that of many other materials. This high refractive index contributes to diamond's ability to bend and focus light effectively, making it suitable for use in lenses and other optical components. The combination of high transmittance and refractive index ensures that diamond optical windows provide clear and accurate imaging and signal transmission, even under challenging conditions.

Comparative Advantages

To further illustrate diamond's superiority in these aspects, consider the following comparison with other common optical materials:

| Material | Refractive Index | Transmittance Range (nm) |

|---|---|---|

| Diamond | 2.42 | 225 - 3500 |

| Sapphire | 1.77 | 170 - 5000 |

| Calcium Fluoride | 1.43 | 130 - 10000 |

Diamond's higher refractive index and broader transmittance range clearly demonstrate its advantages in optical applications. This makes diamond optical windows indispensable in fields such as astronomy, telecommunications, and high-energy physics, where precise and reliable optical performance is paramount.

Absorption Characteristics

Diamond, renowned for its exceptional optical properties, exhibits a unique absorption profile across various wavelengths. While it demonstrates minimal absorption in the majority of the infrared spectrum, there is a notable exception within the 4 to 6 μm range. This range, often critical for many optical applications, is marked by a small intrinsic absorption peak in diamond. This peak, though modest in magnitude, is significant as it stands as the sole absorption feature in this otherwise transparent region.

The presence of this intrinsic absorption peak can be attributed to the fundamental vibrational modes of the diamond lattice. These modes, which are inherent to the crystalline structure of diamond, resonate at specific wavelengths, causing the material to absorb light within this narrow band. Understanding this characteristic is crucial for applications where precise control over optical transparency is essential, such as in infrared spectroscopy and thermal imaging.

In summary, while diamond maintains high transparency across vast portions of the electromagnetic spectrum, its absorption profile in the 4 to 6 μm range is a key feature that must be considered in the design and implementation of optical systems. This intrinsic absorption peak, though small, underscores the importance of detailed material characterization for optimizing performance in advanced optical applications.

Mechanical and Thermal Properties

Hardness and Elasticity

Diamond stands out as the pinnacle of material strength, boasting the highest hardness and modulus of elasticity among all known substances. This unparalleled mechanical resilience is a direct result of its atomic structure, which features a robust three-dimensional network of carbon atoms bonded in a tetrahedral configuration. Each carbon atom is covalently bonded to four others, creating a lattice that is both incredibly strong and resilient to deformation.

The hardness of diamond, measured on the Mohs scale, reaches a perfect score of 10, far surpassing any other natural or synthetic material. This extreme hardness allows diamond to resist scratching and wear, making it ideal for applications where durability is paramount. Similarly, the modulus of elasticity, which quantifies a material's stiffness, is also the highest for diamond. This means that under stress, diamond deforms less than any other material, maintaining its shape and structural integrity even under significant mechanical loads.

| Property | Diamond | Other Materials |

|---|---|---|

| Hardness (Mohs Scale) | 10 | 1-9 |

| Modulus of Elasticity | Highest | Lower |

The combination of these properties makes diamond an exceptional choice for optical windows, particularly in environments where mechanical robustness and resistance to deformation are critical. Whether in high-pressure environments or under constant mechanical stress, diamond's hardness and elasticity ensure that it remains functional and effective over long periods, supporting a wide range of advanced technological applications.

Thermal Conductivity

Diamond stands out for its exceptionally high thermal conductivity, a property that significantly enhances its performance in various applications, particularly in optical windows. Thermal conductivity measures how effectively heat propagates through a material, and diamond's exceptional ability in this regard is due to its unique atomic structure and lack of impurities.

The high thermal conductivity of diamond is primarily attributed to the strong covalent bonds between carbon atoms, which minimize phonon scattering and allow heat to transfer rapidly. This property is particularly advantageous in environments where rapid heat dissipation is crucial, such as in high-power electronics and optical components.

In contrast to many other materials, diamond's thermal conductivity remains high across a wide range of temperatures, making it ideal for use in extreme conditions. This temperature-independent behavior is a result of diamond's isotropic nature, meaning it conducts heat uniformly in all directions, regardless of the spatial orientation of the heat source.

Moreover, diamond's low microwave dielectric loss complements its high thermal conductivity, making it an excellent choice for applications in the microwave frequency range. This dual advantage ensures that diamond optical windows not only handle high-power microwave signals efficiently but also maintain their structural integrity under intense thermal loads.

In summary, diamond's high thermal conductivity and low microwave dielectric loss are key attributes that underscore its superiority as a material for optical windows, particularly in demanding environments where both thermal management and signal integrity are critical.

Chemical Stability

Diamond exhibits remarkable chemical stability, making it an ideal material for applications where durability and resistance to chemical reactions are paramount. This stability is attributed to diamond's strong carbon-carbon bonds, which render it inert to most chemicals, including acids and bases, even under extreme conditions.

Moreover, diamond possesses an exceptionally low coefficient of thermal expansion. This property ensures that the material maintains its structural integrity under varying temperatures, which is crucial for optical windows used in environments with significant thermal fluctuations. The combination of chemical inertness and minimal thermal expansion makes diamond a superior choice for optical windows, particularly in demanding industrial and scientific applications.

Applications of Diamond Optical Windows

Synthesis Methods

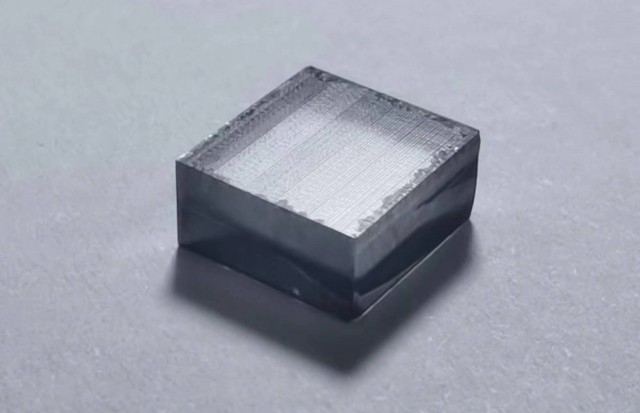

Diamond optical windows are synthesized using a variety of advanced techniques, each tailored to meet specific performance criteria and application demands. The most prominent method is the microwave plasma chemical vapor deposition (CVD) process. This technique involves the use of microwave energy to create a high-temperature plasma that decomposes hydrocarbon gases, such as methane, into carbon atoms. These carbon atoms then precipitate onto a substrate, forming a diamond film.

The CVD process offers several advantages, including precise control over the diamond's properties, such as its purity, grain size, and stress state. This level of control allows for the production of high-quality diamond windows with exceptional optical, mechanical, and thermal properties. Additionally, the CVD process can be scaled up for industrial production, making it a cost-effective solution for large-scale applications.

Other synthesis methods include high-pressure high-temperature (HPHT) processing, which mimics the natural conditions under which diamonds form deep within the Earth. While HPHT is capable of producing large, single-crystal diamonds, it is generally more expensive and less versatile than CVD.

In summary, the synthesis of diamond optical windows leverages cutting-edge technologies like microwave plasma CVD to ensure that these windows meet the stringent requirements of modern optical applications.

Functionality in Extreme Conditions

The diverse geometries of synthetic diamond windows are meticulously designed to ensure optimal performance under the harshest environmental conditions. These windows are engineered to withstand extreme temperatures, ranging from cryogenic levels to the highest operational thresholds, without compromising their structural integrity or optical clarity.

Moreover, the unique mechanical properties of diamond, such as its unparalleled hardness and elasticity, enable these windows to endure significant mechanical stress and pressure variations. This makes them ideal for applications in high-pressure environments, such as those found in industrial machinery or scientific instruments.

In addition to their robustness, diamond windows exhibit superior chemical stability, resisting corrosion and degradation even in the presence of aggressive chemical agents. This attribute is particularly crucial in applications where exposure to harsh chemicals is inevitable, such as in chemical processing plants or in the field of analytical chemistry.

Furthermore, the exceptional thermal conductivity of diamond ensures that these windows can dissipate heat efficiently, maintaining their functionality and longevity even under continuous high-temperature operations. This makes them indispensable in high-power laser systems and other heat-intensive applications.

Overall, the combination of these attributes allows synthetic diamond windows to excel in environments where other materials would fail, making them a superior choice for optical applications in extreme conditions.

Use in Optical Components

Diamond optical windows play a pivotal role in various optical components, particularly in the X-ray, deep ultraviolet, and microwave ranges. These windows are integral to detectors and electronics, where their exceptional transmittance and refractive index are leveraged to optimize performance.

In the X-ray domain, diamond windows are employed in high-resolution imaging and spectroscopy applications. Their high transmittance across the X-ray spectrum ensures minimal signal loss, making them ideal for use in advanced X-ray detectors and imaging systems.

Within the deep ultraviolet range, diamond optical windows are used in UV lasers and photodetectors. The material's ability to transmit light efficiently in this range is crucial for applications in semiconductor manufacturing, where precise UV illumination is necessary for photolithography processes.

For microwave applications, diamond windows are utilized in microwave electronics and communication systems. Their low dielectric loss and high thermal conductivity make them superior to other materials in maintaining signal integrity and thermal stability under high-power microwave conditions.

| Application Range | Key Benefits | Examples of Use |

|---|---|---|

| X-ray | High transmittance, minimal signal loss | High-resolution imaging, X-ray spectroscopy |

| Deep Ultraviolet (UV) | Efficient light transmission, critical for precise UV illumination | UV lasers, photodetectors, semiconductor manufacturing |

| Microwave | Low dielectric loss, high thermal conductivity | Microwave electronics, communication systems |

The versatility and performance of diamond optical windows underscore their importance in advancing optical technologies across multiple spectral ranges.

Importance and Impact

Foundation for Advanced Technology

Diamond's unparalleled properties position it as an indispensable asset in the realm of optical windows, significantly propelling advancements in technology and scientific research. Its exceptional transmittance and refractive index across the ultraviolet, far-infrared, and microwave bands ensure clear and precise optical data transmission, which is crucial for high-resolution imaging and spectroscopy. The material's negligible absorption peaks in the critical 4 to 6 μm range further enhance its performance in these applications.

Moreover, diamond's extraordinary mechanical and thermal properties—including the highest hardness and modulus of elasticity, superior thermal conductivity, and remarkable chemical stability—make it uniquely suited to withstand the rigors of extreme environments. This resilience is vital for optical components operating in conditions where other materials would falter, such as in high-energy physics experiments or aerospace applications.

| Property | Value/Description |

|---|---|

| Transmittance | High across UV, far-IR, and microwave bands |

| Refractive Index | Optimized for diverse optical applications |

| Absorption | Minimal peaks in the 4 to 6 μm range |

| Hardness | Highest among materials |

| Thermal Conductivity | Extremely high, ideal for heat dissipation |

| Chemical Stability | Superior, with low thermal expansion coefficient |

The synthesis of diamond optical windows through advanced methods like the microwave plasma chemical vapor deposition process ensures that these properties are consistently replicated, enabling the production of reliable and high-performance optical components. This synthesis capability, combined with the material's inherent qualities, underscores diamond's pivotal role in supporting cutting-edge technologies and research endeavors.

Related Products

- CVD Diamond Optical Windows for Lab Applications

- CVD Diamond for Thermal Management Applications

- Laboratory CVD Boron Doped Diamond Materials

- Custom CVD Diamond Coating for Lab Applications

- CVD Diamond Domes for Industrial and Scientific Applications

Related Articles

- The Ethics of Diamond Growing Machines

- Optical Quartz Plate: A Comprehensive Guide to Applications, Specifications, and Usage

- Advancements in Diamond Optical Window-Related Components

- Diamond Growing Machines For Modern Machining and Need for New Cutting Tools

- Unveiling the Exceptional Properties and Applications of Optical Quartz Plates