Distance Between Target and Substrate

Energy Loss of Sputtered Particles

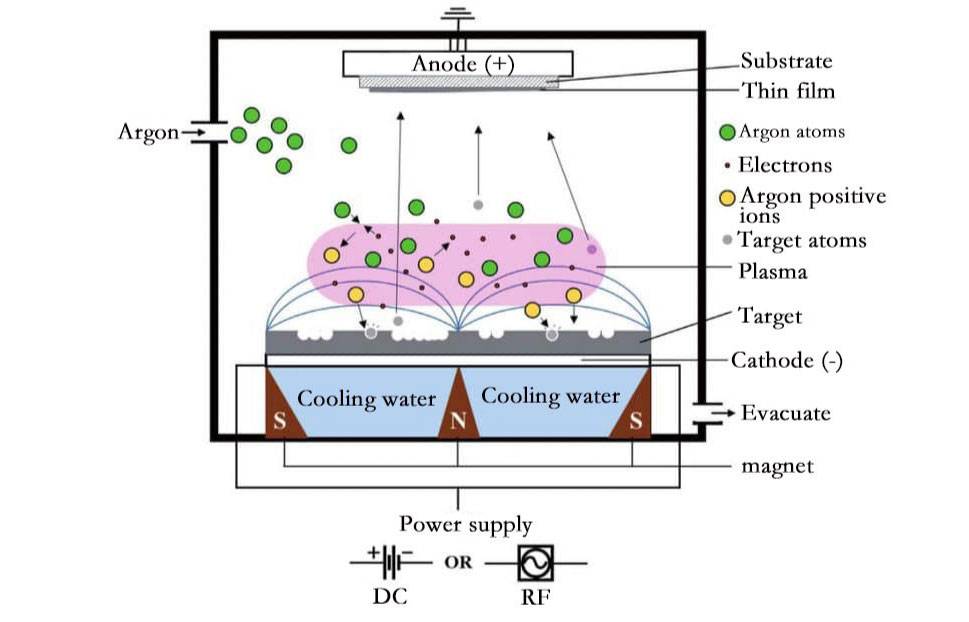

When the distance between the target and the substrate in magnetron sputtering is excessively large, the sputtered particles encounter several challenges that significantly reduce their energy by the time they reach the substrate. This energy loss is primarily due to the increased path length that the particles must traverse, during which they are subjected to various energy-dissipating interactions.

One of the primary mechanisms of energy loss is the interaction with residual gases present in the chamber. As the sputtered particles travel from the target to the substrate, they collide with these gases, which saps their kinetic energy. This phenomenon is particularly pronounced at higher chamber pressures, where the frequency of such collisions increases, further exacerbating the energy loss.

Additionally, the longer the distance, the greater the likelihood of multiple scattering events, where particles deviate from their original trajectory. These deviations not only reduce the particles' energy but also increase the chances of them missing the substrate entirely, leading to a lower deposition efficiency.

The energy loss of sputtered particles can be quantified in terms of their kinetic energy upon arrival at the substrate. Ideally, particles should retain a significant portion of their initial energy to effectively adhere to and integrate with the substrate surface. However, when the distance is too large, the energy retained by the particles is insufficient for effective deposition, resulting in poor film quality or even complete failure of the deposition process.

In summary, the distance between the target and the substrate plays a crucial role in determining the energy state of sputtered particles upon their arrival. An optimal distance must be maintained to ensure that particles retain sufficient energy for effective deposition, thereby avoiding the pitfalls of energy loss and subsequent ineffective film formation.

Air Pressure During Sputtering

Effect on Deposition Efficiency

The air pressure during the magnetron sputtering process plays a critical role in determining the deposition efficiency. When the air pressure is too high, it leads to an increased frequency of particle collisions within the chamber. These collisions can significantly hinder the movement of sputtered particles, causing them to lose energy and scatter before reaching the substrate. Consequently, this reduces the number of particles that successfully deposit on the target, thereby lowering the overall deposition efficiency.

Conversely, if the air pressure is too low, the environment within the chamber becomes less dense. While this might seem beneficial for particle movement, it actually results in an insufficient number of sputtered particles being generated. The reduced particle density means that fewer particles are available to deposit on the substrate, again leading to a drop in deposition efficiency.

To achieve optimal deposition efficiency, it is essential to maintain the air pressure within a specific range. This range allows for a balance between minimizing particle collisions and ensuring a sufficient number of sputtered particles are available for deposition. Fine-tuning the air pressure is thus a crucial aspect of achieving high-quality film deposition in magnetron sputtering processes.

Substrate Temperature

Impact on Film Quality

Lower substrate temperatures can significantly affect the quality of the deposited film. When the substrate temperature is insufficiently high, the atoms deposited on the surface lack the thermal energy necessary to diffuse across the substrate. This diffusion process is crucial for the formation of a continuous and homogeneous film layer. Without adequate diffusion, the film can become discontinuous, leading to areas where the film is either too thin or entirely absent.

Moreover, the inhomogeneity of the film can result in varied mechanical and electrical properties across its surface. For instance, areas with thicker film deposits may exhibit different conductivity or hardness compared to thinner regions. This variability can compromise the overall performance and reliability of the film, particularly in applications where uniformity is critical, such as in microelectronics or optical coatings.

To mitigate these issues, it is essential to carefully control the substrate temperature during the sputtering process. Optimizing this parameter can enhance the diffusion of deposited atoms, thereby improving the continuity and homogeneity of the film. This approach not only ensures better film quality but also enhances the efficiency of the sputtering process, making it more suitable for high-precision applications.

Target Material Characteristics

Behavior During Sputtering

During the sputtering process, the behavior of certain target materials can significantly impact the quality of the deposited film layers. Specifically, some materials may exhibit increased gas production or exhibit unstable deposition behavior under specific conditions, leading to the formation of poorly deposited film layers.

This phenomenon can be attributed to the interaction between the energetic particles bombarding the target material and the intrinsic properties of the material itself. For instance, the binding energy between atoms within the target material plays a crucial role. When the energy of the incident particles reaches a certain threshold, the atoms within the target material begin to escape from the surface, a process known as sputtering. However, if the target material is prone to producing gas or if its atomic structure is unstable under the bombardment conditions, the resulting film layers may be of poor quality.

The efficiency of the sputtering process is also influenced by the energy, angles, and masses of the incident particles. High-energy particles can penetrate deeper into the target material, potentially causing more extensive surface degradation. This can lead to the ejection of not only the desired material but also unwanted gases or impurities, which can further compromise the quality of the deposited film.

In summary, the behavior of target materials during sputtering is a critical factor that can either enhance or degrade the deposition process. Understanding these material-specific challenges is essential for optimizing the sputtering process to achieve high-quality film layers.

Power Supply Settings

Effect on Sputtering Efficiency

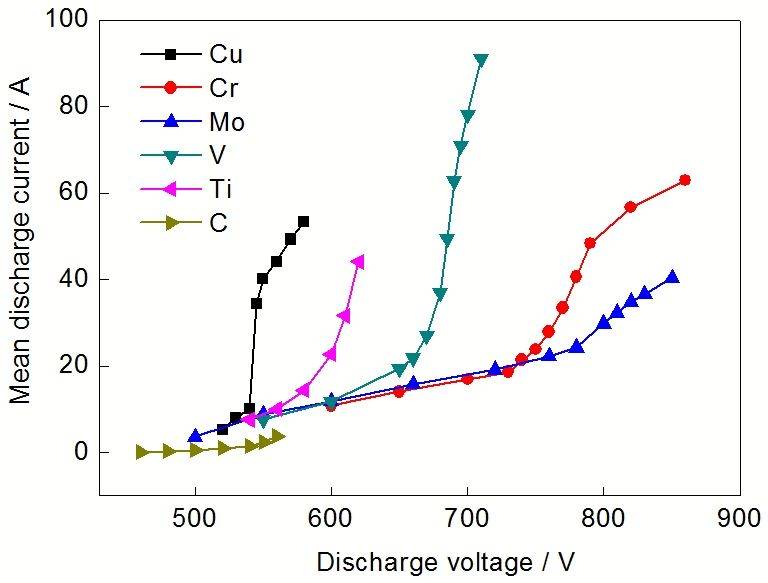

If the power supply settings are not optimized, the target may exhibit a visible glow, yet fail to efficiently sputter the desired number of particles. This discrepancy can be attributed to the intricate relationship between the energy of the bombarding particles and the sputtering yield. The sputtering yield, which quantifies the number of atoms ejected per incident ion, is significantly influenced by the energy and mass of these particles. Generally, within the operative energy range of 10 to 5000 eV, an increase in particle mass and energy tends to enhance the sputtering yield.

The process of sputtering involves the transfer of momentum from incident particles—typically ions of neutral gases—to the target surface. Various parameters, such as the energy, angles, and masses of the incident particles, as well as the binding energy between target atoms, collectively determine the efficiency of this process. As the energy of the colliding ions escalates, they penetrate deeper into the target material's atomic network, disrupting the surface. However, if the energy levels are not precisely calibrated, the ions may either be absorbed or reflected without effectively initiating the sputtering process.

To achieve optimal sputtering efficiency, it is crucial to fine-tune the power supply settings to ensure that the energy levels of the bombarding particles are sufficient to trigger the sputtering mechanism without causing unnecessary surface degradation. This balance is essential for maintaining a high sputtering yield and ensuring the efficient deposition of the target material onto the substrate.

Substrate Surface Condition

Impact on Film Deposition

The cleanliness and roughness of the substrate surface play a crucial role in determining the quality and adhesion of the deposited film layer. Over the past few decades, researchers have increasingly focused on optimizing these factors to enhance the properties of thin films. The emergence of advanced simulation software has further facilitated this process, allowing for more precise control over deposition parameters.

When it comes to substrate surface condition, several key parameters can be adjusted to influence film deposition. These include the number of pumps, the type and number of targets, substrate geometry, reactor occupancy rate, pressure, gas type, gas flow, temperature, current density, and bias. Each of these parameters can impact the deposition rate and the resulting film's adhesion, grain size, and thickness. Consequently, these changes can significantly affect the coating's characteristics, such as its hardness, Young's modulus, morphology, microstructure, and chemical composition.

For instance, a clean substrate surface ensures that the deposited atoms can adhere effectively, while a rough surface can lead to poor adhesion and non-uniform film layers. Similarly, the choice of gas type and flow rate can influence the chemical reactions occurring during deposition, thereby affecting the film's final properties. By carefully controlling these parameters, researchers can achieve more consistent and high-quality film deposition, meeting the demands of various industrial applications.

Sputtering Efficiency of Target Material

Material-Specific Challenges

Different materials exhibit varying sputtering efficiencies, which can significantly impact the deposition process. For instance, some materials may have high sputtering yields, leading to efficient film formation, while others may struggle to release particles under the same conditions. This discrepancy arises due to the inherent properties of the target material, such as its atomic structure, binding energy, and reactivity with the sputtering environment.

Certain materials, such as noble metals or refractory elements, may require specific sputtering conditions to achieve effective deposition. These conditions often include precise control over parameters like power supply settings, air pressure, and substrate temperature. For example, refractory metals like tungsten or molybdenum may require higher energy input to overcome their strong atomic bonds, whereas noble metals like gold or silver may be more susceptible to oxidation if not sputtered under a controlled atmosphere.

Moreover, the complexity of the material's composition can also pose challenges. Multicomponent alloys or compounds may exhibit phase segregation or preferential sputtering of certain elements, leading to non-uniform film deposition. This variability in sputtering behavior necessitates a tailored approach for each material, involving careful optimization of sputtering parameters and often requiring advanced techniques such as reactive sputtering or magnetron sputtering with a bias voltage.

In summary, the effectiveness of film deposition in magnetron sputtering is highly dependent on the specific characteristics of the target material. Understanding and addressing these material-specific challenges is crucial for achieving high-quality, uniform film layers.

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- E Beam Crucibles Electron Gun Beam Crucible for Evaporation

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth