The Fortress Against Nature

A vacuum furnace is an exercise in defiance.

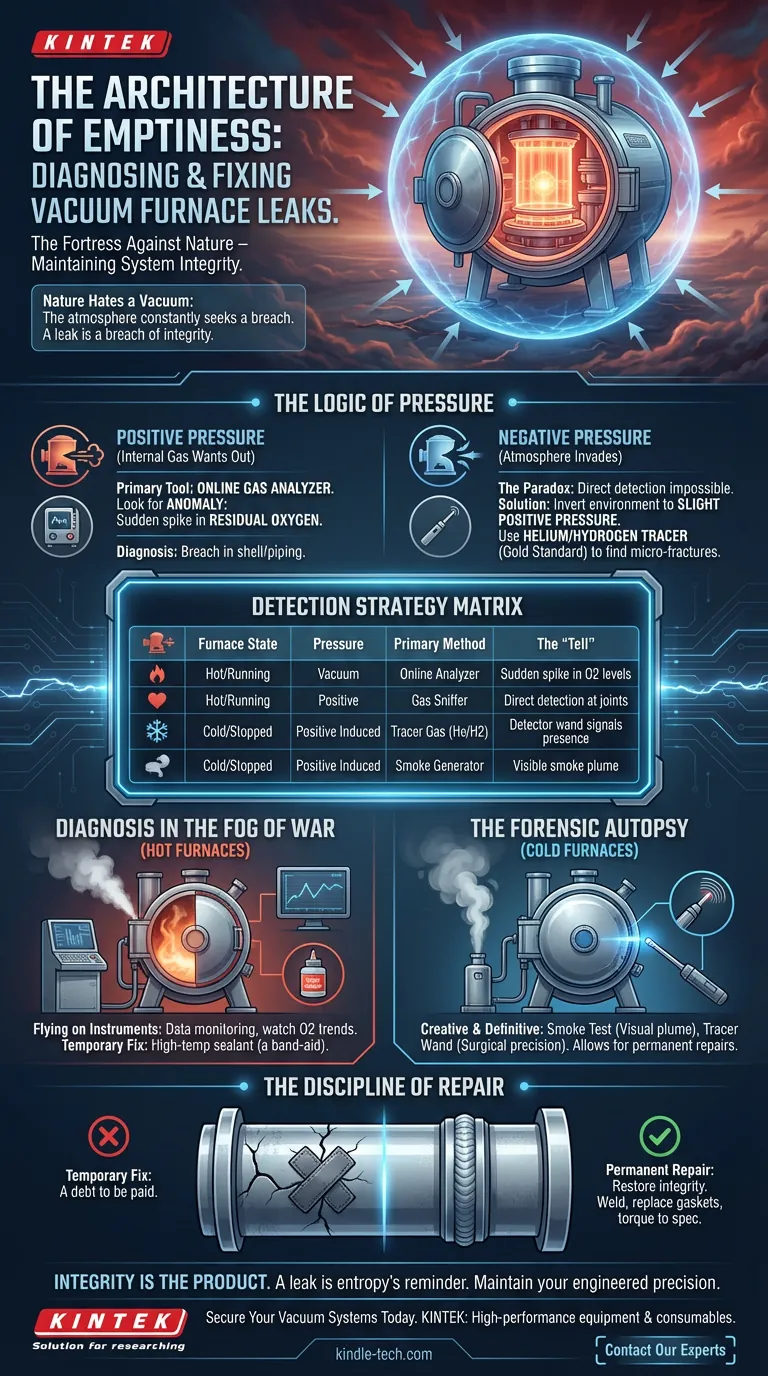

By design, it attempts to create a sanctuary—a space void of atmosphere, where chemistry can occur without the interference of the chaotic world outside. But nature hates a vacuum. The atmosphere is constantly pressing against the steel walls, searching for a weakness, a crack, or a loose seal to rush back in.

When a leak occurs, it is not just a mechanical failure; it is a breach of the system's integrity.

The challenge for the engineer is not merely finding the hole. It is understanding the invisible dynamics of pressure and temperature. It is about applying a systematic, almost medical discipline to diagnosis.

Here is how we maintain the architecture of emptiness.

The Logic of Pressure

To find a leak, you must first understand the battlefield. The behavior of a gas depends entirely on the pressure differential.

Most people imagine a leak as gas escaping. But in a vacuum system, the "leak" is the atmosphere invading. This changes how we must hunt for it.

The Positive Pressure Scenario

If your furnace operates under positive pressure, the physics work in your favor. The internal gas wants to get out.

In this state, your primary diagnostic tool is the online gas analyzer.

You are looking for the anomaly. If you see a sudden, sharp spike in residual oxygen, the diagnosis is almost certainly a breach in the shell or piping. The logic is simple: oxygen shouldn't be there. If it is, the outside world has gotten in.

The Negative Pressure Paradox

Under vacuum (negative pressure), direct detection is nearly impossible. You cannot see what is being sucked in.

To solve this, we must invert the environment.

The most reliable method is to convert the furnace to a slight positive pressure. We force the system to exhale so we can see where the breath escapes. Once pressurized, we use a helium or hydrogen tracer.

Helium is the gold standard because its molecules are tiny—they will escape through micro-fractures that other gases cannot pass, leading your detector straight to the source.

Diagnosis in the Fog of War (Hot Furnaces)

The most stressful leaks happen when the furnace is running. The system is hot. The stakes are high. You cannot touch the vessel.

In this scenario, you are flying on instruments.

You are limited to data monitoring. Your online analyzer becomes your eyes. You watch the gas composition trends. A slow creep in oxygen suggests a seal beginning to fail; a sharp jump suggests a catastrophic breach.

If stopping the cycle is impossible, you may resort to a temporary battlefield dressing. A high-temperature sealant can be applied to the suspect area. It is a band-aid, not a cure, designed only to buy you time until the cycle finishes.

The Forensic Autopsy (Cold Furnaces)

The best work happens when the machine is cold.

When the furnace is shut down, we can move from management to resolution. The cold furnace allows for the most creative and definitive detection methods.

The Smoke Test

There is a primitive elegance to the smoke generator method.

After purging the furnace of combustibles, we ignite a smoke generator inside the vessel. We then pressurize it.

It is visual and undeniable. Smoke will seep out of cracks, flange gaps, or faulty welds. It turns the invisible leak into a visible plume. It is the most effective way to communicate a failure to a team.

The Tracer Wand

For precision, we return to the tracer gas.

With the furnace cold and pressurized with hydrogen (above 3%) or helium, we move a detector wand slowly over every joint, feedthrough, and weld. This is the surgical approach. It pinpoints the exact location of the failure, allowing for targeted repair.

The Discipline of Repair

Finding the leak is only half the battle. Fixing it requires a commitment to standards.

A temporary fix is a debt that must eventually be paid. Permanent repairs—welding cracked parts, replacing aged gaskets, or tightening screws to precise torque specifications—are the only way to restore the system's integrity.

Below is a systematic guide to matching the method to the situation:

Detection Strategy Matrix

| Furnace State | Pressure Condition | Primary Method | The "Tell" |

|---|---|---|---|

| Hot / Running | Vacuum | Online Analyzer | Sudden spike in O2 levels |

| Hot / Running | Positive | Gas Sniffer | Direct detection at joints |

| Cold / Stopped | Positive (Induced) | Tracer Gas (He/H2) | Detector wand signals presence |

| Cold / Stopped | Positive (Induced) | Smoke Generator | Visible smoke plume |

Integrity is the Product

At the end of the day, a leak is a reminder of entropy. It is the natural order trying to assert itself over your engineered precision.

Maintaining a vacuum furnace requires high-quality components and a proactive mindset. It requires realizing that a seal is not just a piece of rubber; it is the gatekeeper of your product's quality.

Is your process integrity under threat?

KINTEK understands that the cost of a leak is measured not just in repairs, but in lost production and compromised science. We specialize in high-performance lab equipment and consumables designed to withstand the rigors of vacuum processing. From robust furnaces to precision replacement parts, we help you keep the atmosphere where it belongs—outside.

Contact Our Experts to discuss how to secure your vacuum systems today.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Graphite Vacuum Furnace Bottom Discharge Graphitization Furnace for Carbon Materials

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Stainless Steel Quick Release Vacuum Chain Three-Section Clamp

Related Articles

- Why Your Heat-Treated Parts Fail: The Invisible Enemy in Your Furnace

- The Architecture of Emptiness: Achieving Metallurgical Perfection in a Vacuum

- Your Vacuum Furnace Hits the Right Temperature, But Your Process Still Fails. Here’s Why.

- Why Your High-Temperature Processes Fail: The Hidden Enemy in Your Vacuum Furnace

- Beyond Heat: Mastering Material Purity in the Controlled Void of a Vacuum Furnace