Blog

Disc / Cup Vibratory Mill: A Comprehensive Guide to Its Functions and Applications

1 year agoDiscover the world of Disc / Cup Vibratory Mills with our in-depth guide. Learn about their working principles, applications, advantages, and key features. Explore the various types of vibratory mills and their suitability for different industries.

Learn More

Electrochemical Cells: Generating Electricity and Driving Reactions

1 year agoElectrochemical cells, like batteries, play a vital role in energy storage by converting chemical energy to electrical energy and vice versa. Explore the workings, types, and significance of these cells.

Learn More

Disc / Cup Vibratory Mill: A Comprehensive Guide for Laboratory Experts

1 year agoDiscover the world of Disc / Cup Vibratory Mills! This comprehensive guide provides an in-depth understanding of their types, working principles, advantages, and applications in various industries, including pharmaceuticals, chemicals, and food processing.

Learn More

PTFE Cleaning Racks: The Ultimate Guide to Cleaning and Drying Labware

1 year agoIn this comprehensive guide, we'll delve into the world of PTFE cleaning racks, exploring their benefits, applications, and the best practices for cleaning and drying labware to ensure optimal performance and longevity.

Learn More

Disc / Cup Vibratory Mill: A Comprehensive Guide to Grinding Equipment

1 year agoDiscover the world of Disc / Cup Vibratory Mills! This guide covers everything from types and features to applications and benefits. Explore the versatility of these mills for grinding various materials in industries like pharmaceuticals, food, and chemicals.

Learn More

PTFE Shovel: A Comprehensive Guide to Its Uses, Advantages, and Applications

1 year agoDiscover the versatile applications of PTFE shovels in various industries, including their unique properties, benefits, and real-world examples. Explore the advantages of PTFE shovels over traditional materials and delve into the specific uses in laboratory settings.

Learn More

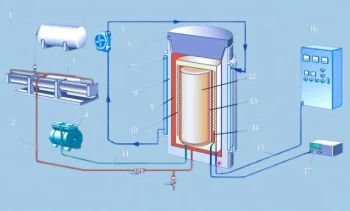

Maximize Rotary Furnace Performance: Design Advancements for Efficient Material Processing

1 year agoDiscover the intricacies of rotary furnaces, exploring their design improvements and applications in advanced materials processing. Learn how these furnaces optimize throughput, energy efficiency, and product quality.

Learn More

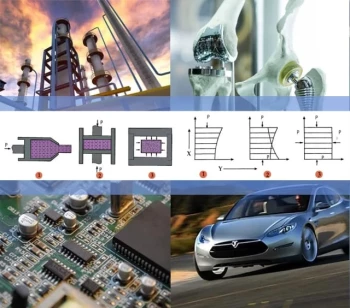

Electrode Fixture Guide: Types, Design, and Applications

1 year agoDiscover the comprehensive guide to electrode fixtures, covering various types, design considerations, and their indispensable role in industries like electroplating, welding, and electrochemical cells.

Learn More

Rotary Furnaces: Advanced Materials Processing and Applications

1 year agoRotary furnaces are versatile and efficient thermal processing systems used in various industries. This comprehensive guide explores the basics of rotary furnaces, their applications, advantages, and key components. Discover how rotary furnaces contribute to advanced materials processing and enhance productivity.

Learn More

Reference Electrodes: Calomel, Silver Chloride, and Mercury Sulfate - A Comprehensive Guide

1 year agoExplore the world of reference electrodes, including calomel, silver chloride, and mercury sulfate. Understand their construction, principles, and applications in electrochemical measurements.

Learn More

Rotary Furnaces: A Comprehensive Guide to Advanced Materials Processing

1 year agoRotary furnaces are widely used for advanced materials processing due to their versatility, temperature uniformity, and energy efficiency. This guide provides an overview of rotary furnace technology, including its working principle, applications, design improvements, and control systems.

Learn More

A Comprehensive Guide to MPCVD: Diamond Synthesis and Applications

1 year agoExplore the fundamentals, advantages, and applications of Microwave Plasma Chemical Vapor Deposition (MPCVD) in diamond synthesis. Learn about its unique capabilities and how it compares to other diamond growth methods.

Learn More

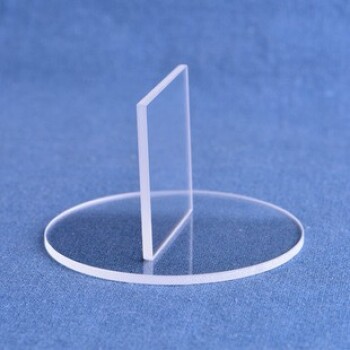

Unlocking the Power of Optical Quartz Plates: Applications and Benefits

1 year agoDelve into the world of optical quartz plates, exploring their exceptional properties, diverse applications in industries like optics, electronics, and more. Discover their advantages, including low thermal expansion, high temperature resistance, and precise optical clarity.

Learn More

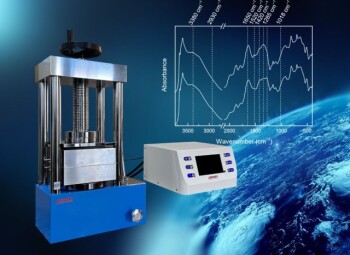

Unveiling the Versatility of Heated Lab Presses: A Comprehensive Guide

1 year agoExplore the world of Heated Lab Presses, delving into their types, applications, key features, safety measures, and maintenance tips. Discover how these versatile tools empower laboratories across diverse industries.

Learn More

Optical Quartz Plate: A Comprehensive Guide to Applications, Specifications, and Usage

1 year agoDiscover the versatility of optical quartz plates, exploring their uses in various industries, key specifications, and factors that differentiate them from glass. Gain insights into their applications in ultraviolet transmission, precision optics, and more.

Learn More

Muffle Furnace: Unraveling the Secrets of Uniform Heating and Controlled Atmosphere

1 year agoDiscover the intricacies of a muffle furnace, an indispensable tool for material processing and analysis. Learn about its working principle, applications, types, features, and benefits, empowering you to make informed decisions for your laboratory or industrial needs.

Learn More

Versatile Applications of PTFE Cleaning Racks: Enhancing Laboratory Efficiency and Precision

1 year agoDelve into the diverse applications of PTFE cleaning racks in laboratory settings. Discover how these essential tools optimize cleaning processes, enhance precision, and contribute to overall laboratory efficiency and accuracy.

Learn More

Unveiling the Exceptional Properties and Applications of Optical Quartz Plates

1 year agoDiscover the remarkable characteristics and diverse applications of optical quartz plates, including their superior ultraviolet transmission, thermal stability, and use in lenses, lighting devices, and semiconductor manufacturing.

Learn More

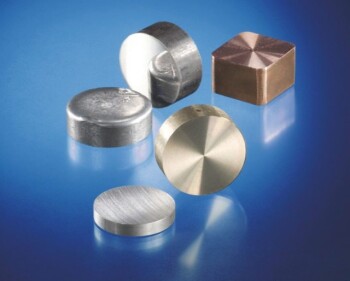

Electrochemical Consumables: A Comprehensive Guide to Materials, Applications, and Selection

1 year agoDiscover the world of electrochemical consumables, including types of electrodes (working, auxiliary, and reference) and electrolytes, as well as factors to consider when selecting materials for your electrochemical experiments or applications.

Learn More

Vacuum Induction Melting Furnace vs Arc Melting Furnace: Choosing the Right Equipment for Your Process

1 year agoLearn about the key differences between vacuum induction melting furnaces and arc melting furnaces, including their advantages and applications, to help you choose the best equipment for your specific needs.

Learn More

Electric Rotary Kiln Pyrolysis Furnace: A Comprehensive Guide to Pyrolysis Technology

1 year agoDiscover the principles, applications, and advantages of electric rotary kiln pyrolysis furnaces. Explore various heating methods, factors affecting efficiency, and the environmental benefits of this technology.

Learn More

Automatic Hydraulic Press: The Ultimate Guide for Efficient Sample Preparation and Industrial Processes

1 year agoDiscover the world of automatic hydraulic presses, from their versatile applications in industrial XRF and laboratory sample manipulation to their role in large-scale manufacturing, hot embossing, laminating, and polymer melting. Learn about their benefits, features, and how they revolutionize sample preparation and industrial processes.

Learn More

Unveiling the World of Heated Lab Presses: A Comprehensive Guide

1 year agoDiscover the versatility of heated lab presses in various applications, from sample preparation to material testing. Explore key factors to consider when purchasing a lab press, including pressure, temperature, platen size, and control options.

Learn More

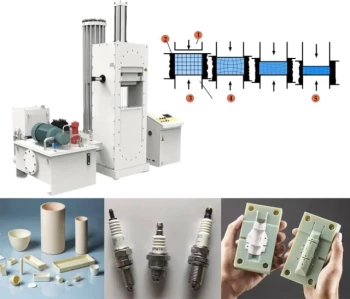

Understanding Cold Isostatic Pressing: Application, Advantages, and Limitations

1 year agoCold Isostatic Pressing (CIP) is a widely used manufacturing process in various industries, including ceramics, metalworking, and pharmaceuticals. It involves applying equal pressure from all directions to a material placed inside a flexible mold or bag. This process helps in achieving uniform density and shaping complex components with intricate geometries.

Learn More

Understanding the Principles and Applications of Isostatic Pressing

1 year agoIn this process, the powder is filled in a mold and sealed tightly. This occurs outside the pressure vessel. After filling the mold with powder, the mold is submerged in the pressure fluid within the pressure vessel. Then isostatic pressure is applied to the external surface of the mold, compressing the powder into a solid mass.

Learn More

Isostatic Pressing: Methods, Applications and Comparison with Other Compaction Methods

1 year agoIsostatic pressing is a compaction method that offers unique advantages in achieving uniform density and creating complex shapes. Unlike other compaction methods, isostatic pressing utilizes flexible molds to reduce friction and allow for intricate designs.

Learn More

Comprehensive Overview of Warm Isostatic Press and Its Applications

1 year agoWarm isostatic pressing (WIP) is a variant of cold isostatic pressing (CIP) that includes a heating element. It employs warm water or a similar medium to apply uniform pressure to powdered products from all directions. WIP is a cutting-edge technology that enables isostatic pressing at a temperature that does not exceed the boiling point of the liquid medium.

Learn More

Understanding the Isostatic Pressing Process: Origins, Types, and Applications

1 year agoThe isostatic pressing process was pioneered in the mid-1950s and has steadily grown from a research curiosity to a viable production tool. Many industries apply this technique for consolidation of powders or defect healing of castings.

Learn More

Warm Isostatic Pressing: An Advanced Manufacturing Technology

1 year agoWarm Isostatic Pressing (WIP) is a cutting-edge technology that enables isostatic pressing at a temperature that does not exceed the boiling point of the liquid medium. It is a variant of cold isostatic pressing (CIP) that includes a heating element.

Learn More

Understanding Cold Isostatic Pressing and Its Applications

1 year agoCold isostatic pressing (CIP) is a method of processing materials. It involves compacting powders by enclosing them in an elastomer mold and applying uniform liquid pressure to compress the mold. This results in a highly compact solid. Cold isostatic pressing is commonly used for plastics, graphite, powdered metallurgy, ceramics, sputtering targets, and other materials.

Learn More