Maintenance and Efficiency

Maintenance of Induction Coils

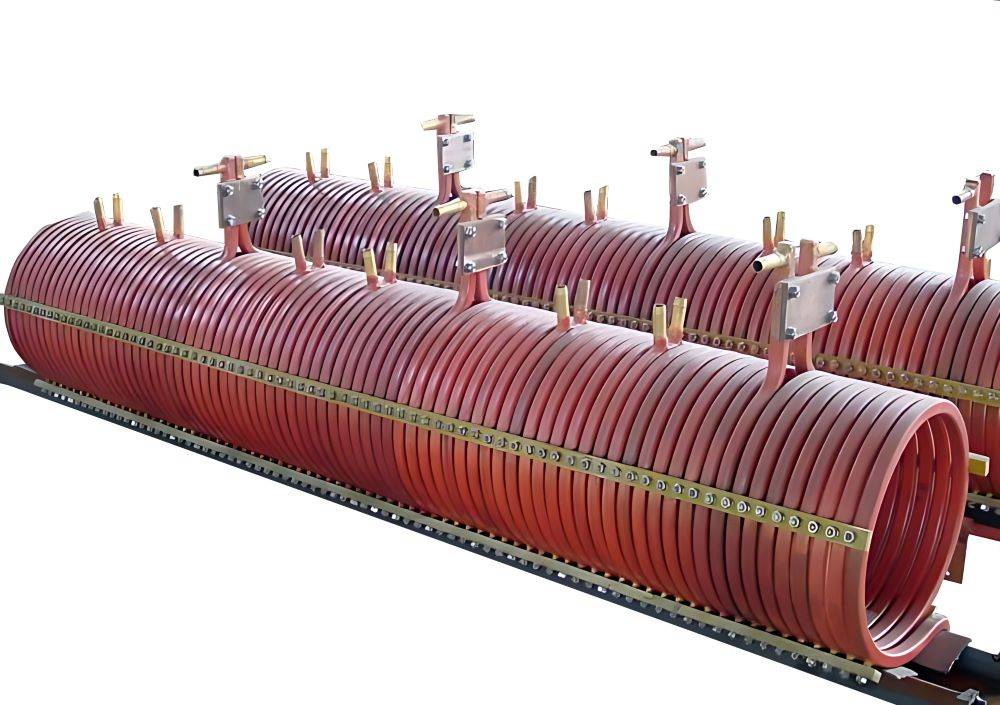

To ensure the longevity and optimal performance of induction coils, meticulous maintenance practices must be adhered to. Daily cleaning is paramount, involving the use of soap and hot water to thoroughly remove any adhering hardeners and debris. This routine cleaning not only preserves the coil's integrity but also prevents the accumulation of materials that could compromise its efficiency over time.

In addition to daily cleaning, regular inspections are crucial. These inspections should focus on identifying any signs of wear or damage, such as cracks or frayed wires, which could lead to more significant issues if left unaddressed. By conducting these inspections regularly, potential problems can be caught early, allowing for timely repairs and reducing the likelihood of costly breakdowns.

Moreover, it is essential to store induction coils properly when not in use. This involves keeping them in a clean, dry environment to prevent corrosion and other forms of degradation. Proper storage not only extends the lifespan of the coils but also ensures they are ready for immediate use without the need for extensive cleaning or preparation.

By integrating these maintenance practices into your routine, you can significantly enhance the durability and efficiency of your induction coils, contributing to a more sustainable and cost-effective heat treatment process.

Energy Savings in Vacuum Furnaces

The utilization of advanced insulation materials, such as graphite felts, plays a pivotal role in enhancing the energy efficiency of vacuum furnaces. These materials are specifically designed to minimize heat loss, thereby reducing the overall energy consumption of the furnace. By implementing thicker insulation, the efficiency of the furnace can be improved by up to 25%, a significant boost in energy savings.

Vacuum furnaces are inherently efficient machines, capable of precise energy management through programmable logic controls (PLCs). These controls allow the furnace to follow a desired heating-cooling curve, ensuring that heating power is only provided when necessary. During idle times, cooling phases, or when the furnace is being loaded or unloaded, no heating power is consumed, further optimizing energy usage.

The energy absorbed by a vacuum furnace is primarily used for heating, which can be broken down into three main components:

- Energy for Heating the Workload and Fixtures: This involves the energy required to raise the temperature of the materials being processed and the fixtures that hold them.

- Energy for Heating the Furnace Hot Zone: This component refers to the energy needed to maintain the high temperatures within the furnace's hot zone.

- Dissipated Energy: This includes any energy lost through conduction, convection, or radiation within the furnace.

The relationship between the mass of the load and the energy consumption is not linear. While heavier loads will naturally require more energy, the efficiency of the furnace's closed-loop control system, based on a PID controller, ensures that only the necessary amount of energy is consumed. This precise control system eliminates wasteful energy usage, making vacuum furnaces a highly efficient option for heat treatment processes.

Material and Process Improvements

Thinner Steel for Lighter Cars

The automotive industry is increasingly demanding high-strength, lightweight steel to enhance vehicle performance and fuel efficiency. To meet these requirements, manufacturers are employing advanced heat treatment techniques and incorporating specific alloying elements into the steel composition.

Heat treatment processes, such as quenching and tempering, play a crucial role in achieving the desired mechanical properties. These processes involve rapid cooling of the steel to induce a hard, martensitic structure, followed by controlled heating to temper the steel, thereby improving its toughness and ductility without compromising its strength.

In addition to traditional heat treatment methods, the use of quench partitioning has gained prominence. This technique involves a two-step heat treatment process where the steel is first quenched to form a partially martensitic structure, and then subjected to a partitioning step to redistribute carbon atoms within the microstructure. This results in a more uniform and refined microstructure, enhancing both strength and toughness.

Thermodynamic modeling is also integral to the validation of these processes. By simulating the heat treatment conditions and alloy compositions, engineers can predict the resulting microstructures and properties of the steel. This approach not only reduces the need for extensive experimental trials but also optimizes the heat treatment parameters for the specific alloy being used.

The combination of these advanced techniques allows for the production of thinner, yet stronger, steel components, significantly contributing to the overall weight reduction of vehicles. This not only improves fuel efficiency but also enhances the safety and performance of modern automobiles.

Preservation of Workholding Fixtures

Proper storage and maintenance of workholding fixtures is crucial to prevent deformation and ensure their longevity. These fixtures, which are essential for securing workpieces during heat treatment processes, can experience significant stress and wear. To mitigate these issues, fixtures should be stored in a controlled environment where temperature and humidity are regulated. This helps in preventing warping and rusting, which can compromise the precision and integrity of the fixtures.

Cooling power supplies with deionized water is another critical practice for maintaining fixture efficiency. Deionized water is free from impurities that can cause mineral buildup, which can lead to overheating and damage. By using deionized water, the cooling system operates more efficiently, ensuring that the fixtures remain at optimal temperatures. This not only extends the life of the fixtures but also enhances the overall efficiency of the heat treatment process.

Additionally, regular inspections and maintenance routines should be established to identify and address any signs of wear or damage promptly. This proactive approach ensures that any issues are resolved before they can escalate, thereby preserving the functionality and reliability of the workholding fixtures.

Technological Innovations

Improving Vacuum Furnace Efficiency

The integration of AC to DC transformers plays a pivotal role in optimizing vacuum furnace efficiency by stabilizing power fluctuations and reducing overall energy consumption. These transformers not only dampen the erratic energy spikes that can occur during operation but also ensure that the furnace operates consistently at its peak efficiency, thereby minimizing power factor charges.

Vacuum furnaces, while inherently efficient, rely heavily on precise control systems, such as Programmable Logic Controllers (PLCs), to manage their heating and cooling cycles. These systems are designed to deliver heating power only when necessary, such as during active workload processing, and to switch off during idle times or cooling phases. This strategic approach to energy management ensures that the furnace operates with minimal waste, contributing significantly to overall energy savings.

In addition to the primary heating system, vacuum furnaces are equipped with several auxiliary systems, including water-cooling systems, gas cooling systems, and vacuum pumps. These subsystems, though essential for maintaining furnace performance, collectively contribute to non-negligible energy consumption. By leveraging advanced transformers and optimizing operational parameters, manufacturers can further mitigate these auxiliary energy demands, enhancing the overall efficiency of the vacuum furnace setup.

The energy absorbed by a vacuum furnace is primarily utilized for three key purposes: heating the workload and fixtures, heating the furnace's hot zone, and managing energy dissipation. Each of these components requires careful monitoring and efficient energy distribution to ensure that the furnace operates at its most effective level. Furthermore, the vacuum environment itself offers unique advantages, such as significantly reduced partial pressures of residual air (oxygen and water vapor), which helps in processing components with minimal surface oxidation. This environment also facilitates the decomposition of existing oxides on component surfaces, depending on the temperature and material type, further enhancing the quality and efficiency of the heat treatment process.

By adopting these strategies and technologies, manufacturers can significantly improve the efficiency of their vacuum furnaces, leading to reduced operational costs and a more sustainable heat treatment process.

Burner Adjustment and Calibration

Proper burner adjustment and calibration are paramount for maintaining operational efficiency, minimizing emissions, and extending the lifespan of heating equipment. This process involves meticulous tuning of several critical factors, each playing a vital role in optimizing the burner's performance.

Firstly, combustion air must be precisely controlled. The correct balance of air and fuel ensures complete combustion, which not only maximizes energy output but also minimizes the formation of harmful byproducts such as carbon monoxide and unburned hydrocarbons. Modern systems often incorporate automated air-fuel ratio controllers that continuously adjust based on real-time data, ensuring optimal combustion conditions.

Secondly, gas usage is another key consideration. Efficient gas utilization can significantly enhance the overall performance of the burner. Advanced burner designs, such as those with pre-mix technology, can achieve higher combustion efficiencies by thoroughly mixing gas and air before ignition. This reduces the amount of gas needed for a given heat output, thereby lowering operational costs and environmental impact.

Lastly, supply pressures must be meticulously managed. Fluctuations in gas pressure can lead to inconsistent combustion, affecting both efficiency and emissions. Stabilizing supply pressures through the use of pressure regulators and monitoring systems ensures a steady and reliable fuel flow, which is essential for maintaining burner performance over time.

In summary, the careful calibration of burners involves balancing combustion air, optimizing gas usage, and stabilizing supply pressures. These practices not only enhance the efficiency of heating equipment but also contribute to a cleaner, more sustainable operation.

Control and Monitoring

Consistent Heating Control

One of the key advancements in modern heating systems is the implementation of power feedback mechanisms for electric heating elements. This innovative approach shifts the focus from traditional control methods, such as monitoring current or voltage alone, to a more holistic power-based control system. By integrating power feedback, the system can more accurately regulate the amount of energy being delivered to the heating elements, ensuring a more consistent and efficient heat output.

This method is particularly beneficial in applications where precise temperature control is critical, such as in vacuum furnaces or induction heating systems. The power feedback system continuously monitors the actual power consumption and adjusts the heating elements accordingly, thereby minimizing fluctuations and maintaining a steady heat level. This not only enhances the overall efficiency of the heating process but also extends the lifespan of the heating elements by preventing overuse and overheating.

In summary, the use of power feedback for electric heating elements represents a significant step forward in achieving more precise and sustainable heating control. This technology not only optimizes energy usage but also contributes to the longevity and reliability of heating systems, making it an essential component in modern heat treatment processes.

Combustion Efficiency Monitoring

Real-time monitoring of combustion data is crucial for maintaining high efficiency and minimizing emissions. This process involves the precise control of fuel-air mixing to achieve optimal heat output, which is essential for both energy conservation and environmental protection.

Key Aspects of Combustion Efficiency Monitoring

-

Fuel-Air Mixing:

- Optimal Ratios: Ensuring the correct balance between fuel and air is vital. This balance maximizes heat production while minimizing waste gases like CO and CO2.

- Dynamic Adjustments: Modern systems can dynamically adjust fuel-air ratios based on real-time data, enhancing efficiency and reducing emissions.

-

Emission Reduction:

- Low NOx Emissions: Techniques such as staged combustion and flameless oxidation help in reducing nitrogen oxides (NOx) emissions, which are harmful to the environment.

- CO and CO2 Management: Proper fuel-air mixing also aids in controlling carbon monoxide (CO) and carbon dioxide (CO2) emissions, contributing to cleaner air.

-

Energy Efficiency:

- Heat Utilization: Efficient combustion ensures that more of the generated heat is utilized, reducing the need for additional energy inputs.

- Operational Costs: By maintaining high combustion efficiency, operational costs are reduced, as less fuel is required to achieve the same heat output.

Table: Comparison of Combustion Efficiency Techniques

| Technique | Advantages | Disadvantages |

|---|---|---|

| Staged Combustion | Reduces NOx emissions | Complex control systems required |

| Flameless Oxidation | Lowers CO and CO2 emissions | Higher initial setup costs |

| Dynamic Fuel-Air Mixing | Optimizes heat output and reduces emissions | Requires advanced monitoring systems |

By implementing these advanced combustion efficiency monitoring techniques, industries can significantly enhance their operational efficiency and contribute to a more sustainable environment.

Sustainability and Green Practices

Induction Hardening Tips

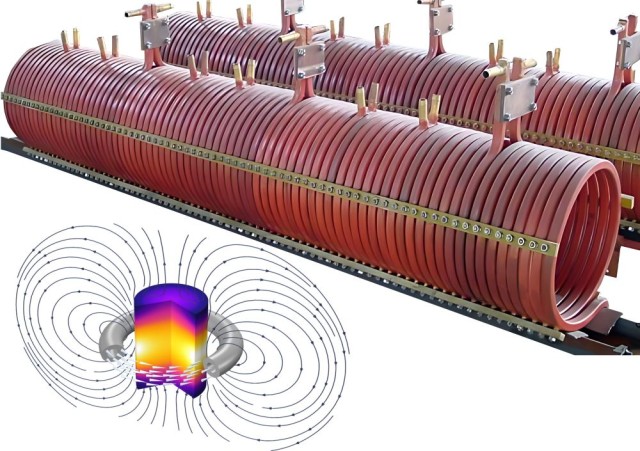

Induction hardening offers a myriad of advantages that make it a preferred choice in various industrial applications. One of the most significant benefits is space savings. Unlike traditional heating methods that require bulky equipment, induction hardening uses compact coils that can be easily positioned around the workpiece, optimizing workspace utilization.

Energy efficiency is another standout feature. Induction heating is highly efficient as it directly heats the material without heating the surrounding air or equipment. This targeted heating reduces energy waste, making it a cost-effective solution. Additionally, the rapid heating and cooling cycles inherent in induction hardening contribute to its energy-saving potential.

The process is also renowned for its cleanliness. Induction hardening eliminates the need for oils, salts, or other media that are typically used in conventional heat treatments. This results in a cleaner working environment and reduces the risk of contamination, which is particularly important in industries where precision and cleanliness are paramount.

Low distortion is a critical advantage, especially for parts that require precise dimensions. The localized heating ensures that only the surface layer of the material is affected, minimizing the risk of warping or deformation. This makes induction hardening ideal for components that undergo multiple heat treatment processes.

Lastly, induction hardening boasts low maintenance costs. The equipment is robust and requires minimal upkeep compared to other heat treatment methods. The lack of consumable materials further reduces operational costs, making it a financially attractive option for long-term use.

In summary, induction hardening's benefits—space savings, energy efficiency, cleanliness, low distortion, and low maintenance costs—position it as a superior choice for modern manufacturing needs.

Conversion to Water-Based Lubricants

Transitioning to water-based lubricants offers a myriad of environmental and operational benefits. These lubricants are not only eco-friendly but also enhance the efficiency of industrial processes. One of the key advantages is their compatibility with alkaline degreasing fluids, which effectively remove these lubricants from surfaces. This compatibility ensures that the cleaning process is both thorough and efficient, reducing the risk of contamination and improving the overall quality of the treated materials.

Moreover, water-based lubricants are significantly less hazardous compared to their oil-based counterparts. They produce fewer volatile organic compounds (VOCs), which are known pollutants that can harm both human health and the environment. By minimizing VOC emissions, industries can adhere to stricter environmental regulations and reduce their carbon footprint.

In addition to their environmental benefits, water-based lubricants can improve operational efficiency. They are often easier to handle and apply, requiring less complex equipment and maintenance. This simplicity translates to cost savings and reduced downtime, making them an attractive option for various industrial applications.

Furthermore, the use of alkaline degreasing fluids in conjunction with water-based lubricants ensures that the removal process is both effective and sustainable. These fluids are designed to break down and eliminate water-based lubricants efficiently, leaving surfaces clean and ready for subsequent processing steps. This dual approach not only enhances the sustainability of the process but also ensures that the end product meets high-quality standards.

In summary, the conversion to water-based lubricants, coupled with the use of alkaline degreasing fluids, represents a significant step towards sustainable industrial practices. It not only reduces environmental impact but also enhances operational efficiency and product quality.

Diagnostic and Management Systems

Improving Furnace Efficiency

Utilizing advanced diagnostics is pivotal in enhancing the efficiency of heating furnaces. This approach involves a multi-faceted monitoring system that ensures optimal performance and early detection of potential issues. Key elements of this monitoring include:

-

Terminal Connections: Regular inspection and maintenance of terminal connections are crucial. Corrosion or loose connections can lead to energy losses and operational inefficiencies. By using diagnostic tools, such as thermal imaging cameras, technicians can identify and rectify issues before they escalate.

-

Heater Fault Alarms: Implementing real-time heater fault alarms provides a proactive approach to maintenance. These alarms can detect anomalies such as overheating or malfunctioning components, allowing for immediate intervention. This not only prevents costly downtime but also extends the lifespan of the furnace.

-

Plant Load Management Systems: Efficient plant load management systems are essential for optimizing energy usage. These systems monitor and adjust the load based on real-time data, ensuring that the furnace operates at peak efficiency. Techniques such as load balancing and predictive maintenance can significantly reduce energy consumption and operational costs.

By integrating these diagnostic tools and management systems, industries can achieve substantial improvements in furnace efficiency, leading to reduced operational costs and enhanced sustainability.

Equipment Selection Considerations

When selecting induction heating equipment, several critical factors must be meticulously considered to ensure optimal performance and efficiency. These factors encompass a range of technical and operational aspects that directly influence the design and functionality of the equipment.

Material and Microstructure

The choice of material is paramount as it directly affects the heating process. Different materials have varying thermal conductivities and specific heat capacities, which impact the rate and uniformity of heating. For instance, metals with high thermal conductivity, like copper and aluminum, require different heating strategies compared to those with lower conductivity, such as stainless steel. Additionally, the microstructure of the material, including its grain size and phase distribution, plays a significant role in determining the effectiveness of the induction heating process. Fine-grained materials may require more precise control over heating parameters to avoid structural changes that could compromise the material's integrity.

Geometry and Power Requirements

The geometry of the workpiece is another crucial factor. Complex shapes and varying thicknesses necessitate sophisticated heating patterns to ensure uniform distribution of heat. For example, a cylindrical workpiece will heat differently than a flat plate, requiring adjustments in the coil design and power distribution. The power requirements for induction heating are also influenced by the geometry; larger or denser workpieces may require higher power levels to achieve the desired temperature within a reasonable timeframe. Conversely, smaller or less dense workpieces can be heated with lower power settings, optimizing energy consumption.

Process Development Needs

The development and refinement of the heating process are essential for achieving consistent results. This involves understanding the specific thermal needs of the application, such as the required temperature range, heating rate, and cooling requirements. Advanced process control systems can be employed to monitor and adjust these parameters in real-time, ensuring that the induction heating process meets the desired specifications. Additionally, continuous process development can lead to improvements in efficiency and reliability, reducing downtime and operational costs.

By carefully considering these factors—material and microstructure, geometry, power requirements, and process development needs—engineers can design and select induction heating equipment that not only meets current demands but also anticipates future technological advancements.

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Infrared Heating Quantitative Flat Plate Press Mold

- Double Plate Heating Press Mold for Lab

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

Related Articles

- The Art of Absence: Why Advanced Materials Demand Vacuum Furnaces

- The Symphony of Silence: Molybdenum and the Architecture of the Vacuum Hot Zone

- Your Vacuum Furnace Hits the Right Temperature, But Your Process Still Fails. Here’s Why.

- Molybdenum Vacuum Furnace: High-Temperature Sintering and Advanced Applications

- Molybdenum Vacuum Furnace: High-Temperature Sintering and Heat Treatment