Blog

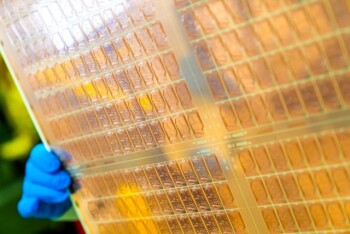

Choosing Microplates for Zymography Assays

9 months agoGuidelines on selecting appropriate microplates for various zymography assay detection modes.

Learn More

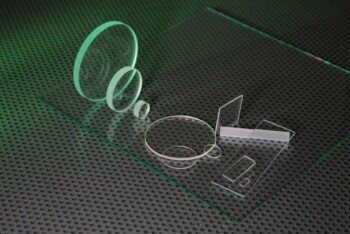

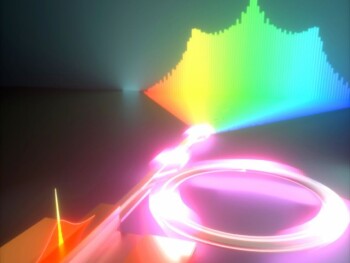

Technological Innovations in the Fused Silica Industry

9 months agoExplore advancements in fused silica, its applications, and future prospects.

Learn More

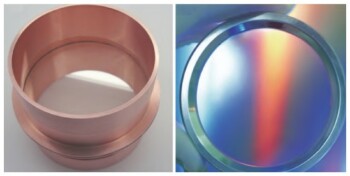

Difference between Single Crystal Quartz and Fused Silica

9 months agoA detailed comparison of single crystal quartz and fused silica across various properties and preparation methods.

Learn More

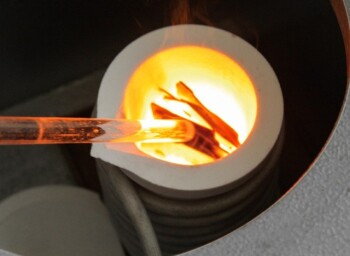

Fused Silica Crucible: Properties, Applications, and Preparation Process

9 months agoAn in-depth look at the properties, applications, and preparation methods of fused silica crucibles in the solar photovoltaic industry.

Learn More

Key Properties and Differences Between Fused Silica and Natural Quartz

9 months agoA detailed comparison of the properties, appearance, physical, chemical, and application differences between fused silica and natural quartz.

Learn More

Understanding Fused Silica: Properties, Applications, and Advantages

9 months agoAn in-depth look at fused silica, its unique properties, and its diverse applications in various industries.

Learn More

Comprehensive Overview of Fused Silica: Properties, Production, Applications, and Market Prospects

9 months agoAn in-depth exploration of fused silica, its properties, production process, diverse applications, and promising market outlook.

Learn More

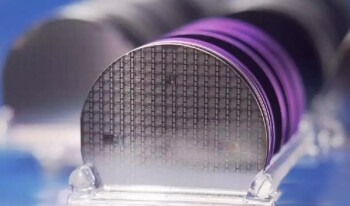

The Rise of Glass Substrates in Advanced Semiconductor Packaging

9 months agoExplores the shift towards glass substrates in advanced semiconductor packaging, their advantages, and challenges.

Learn More

Infrared Bands and Window Selection for Hypersonic Vehicles

9 months agoExplores the challenges and solutions in selecting infrared bands and window materials for hypersonic vehicles, focusing on imaging and guidance systems.

Learn More

CVD Diamond: Superior Material for Optical Windows

9 months agoExplores the exceptional properties and applications of CVD diamond in optical windows.

Learn More

Optical Components: Window Sheets and Their Applications

9 months agoAn overview of various types of optical window sheets, their materials, precision, and coating options.

Learn More

CVD Diamond Optical Windows: Advancing High-Tech Optical Applications in Extreme Environments

9 months agoExploring the benefits of CVD diamond optical windows for high-end applications in extreme environments, including aerospace, military, and scientific research.

Learn More

Advancements in Diamond Optical Window-Related Components

9 months agoExplores the development and applications of diamond optical window components in various fields, including defense, aerospace, and energy.

Learn More

Factors in Selecting Large Optical Windows

9 months agoConsiderations for choosing large optical windows, including material, polishing, and coating.

Learn More

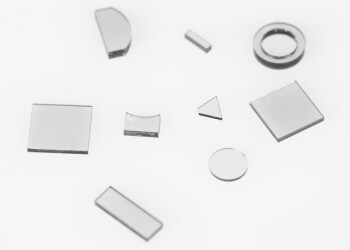

Comprehensive Guide to Optical Windows: Material Properties and Surface Specifications

9 months agoThis article delves into the properties and specifications of optical windows, focusing on material properties, surface quality, and anti-reflection coatings.

Learn More

Optical Window Sheet Selection Guide

9 months agoA comprehensive guide on selecting optical window sheets based on substrate material, optical and mechanical precision, and coating options.

Learn More

Graphite Crucible in the Future Production of Third Generation Semiconductor Compounds

9 months agoExplores the role and future trends of graphite crucibles in the production of third-generation semiconductor materials.

Learn More

High Purity Graphite Crucible: Features, Production, and Usage

9 months agoAn in-depth look at high purity graphite crucibles, their production processes, and their industrial applications.

Learn More

Preparation Methods for High Purity Aluminum Oxide

9 months agoAn overview of various methods to produce high purity aluminum oxide, including hydrolysis, pyrolysis, modified Bayer, precipitation, baking, sol-gel, and spark discharge methods.

Learn More

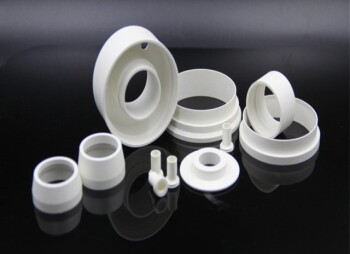

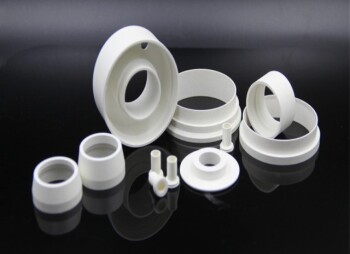

Inorganic Non-Metallic Materials: Crucibles

10 months agoAn overview of crucibles made from various inorganic non-metallic materials, their uses, technical parameters, and advantages.

Learn More

Preventing Sample Bonding in Aluminum Oxide Crucible Sintering

10 months agoStrategies to prevent sample bonding during sintering in aluminum oxide crucibles.

Learn More

Preparation and Performance of Alumina Crucibles for Vacuum Induction Melting Furnace

10 months agoThis article discusses the preparation process and performance benefits of alumina crucibles for vacuum induction melting furnaces, emphasizing thermal stability and long service life.

Learn More

Ceramic Alumina Crucible for Thermal Analysis Test Containers

10 months agoAn in-depth guide on selecting and using ceramic alumina crucibles for thermal analysis tests, focusing on factors affecting test results.

Learn More

Alumina Crucibles in Precision Casting

10 months agoExplores the use of alumina crucibles in precision casting, focusing on their properties and advantages in high-temperature alloy melting.

Learn More

Comprehensive Guide to Alumina Crucibles in Powder Metallurgy

10 months agoAn in-depth look at the properties, applications, and usage of alumina crucibles in powder metallurgy processes.

Learn More

Crucible Types, Properties, and Applications

10 months agoA detailed overview of various crucible types, their properties, and application areas in laboratory and industrial settings.

Learn More

Introduction to Various Ceramic Crucibles

10 months agoAn overview of different types of ceramic crucibles, their properties, and applications.

Learn More

The Role and Types of Crucibles in Scientific Experiments

10 months agoExplores the significance and various types of crucibles in scientific experiments, focusing on their materials and applications.

Learn More

Comparison of Pyrolytic Graphite and Pyrolytic Boron Nitride Crucibles

10 months agoA detailed comparison of pyrolytic graphite and pyrolytic boron nitride crucibles, focusing on their preparation processes, characteristics, and applications.

Learn More

Guidelines for the Use of Boron Nitride Crucibles

10 months agoInstructions on the proper use, precautions, and compatibility of boron nitride crucibles.

Learn More