Temperature Considerations

Maximum and Continuous Working Temperatures

When selecting a laboratory tube furnace, it is crucial to consider both the maximum and continuous working temperatures. The maximum temperature refers to the peak temperature the furnace can reach for short durations, typically less than an hour. This parameter is essential for processes that require rapid heating or sudden temperature spikes.

On the other hand, the continuous safe working temperature is the temperature at which the furnace can operate safely over extended periods without compromising its structural integrity or performance. This is particularly important for experiments that demand prolonged heating cycles, such as sintering or annealing processes.

| Temperature Type | Description | Duration | Importance |

|---|---|---|---|

| Maximum Temperature | The highest temperature the furnace can achieve for short periods. | <1 hour | Critical for rapid heating or sudden temperature spikes. |

| Continuous Working Temperature | The temperature at which the furnace can operate safely over extended periods. | Extended durations | Vital for processes requiring prolonged heating cycles, like sintering. |

Understanding these temperature limits helps in aligning the furnace's capabilities with the specific requirements of your laboratory experiments, ensuring both safety and optimal performance.

Types of Heating Elements

The heating element is a critical component that determines the maximum working temperature of a laboratory tube furnace. Various types of heating elements are available, each suited for different temperature ranges and applications.

Resistance Wire Heating Elements

Resistance wire elements operate within a temperature range of 250-1250°C. These elements are commonly made from materials like nichrome, which is composed of 80% nickel and 20% chromium. Nichrome is particularly favored due to its high resistance and the formation of a protective chromium oxide layer upon initial heating, which prevents further oxidation and extends the element's lifespan. Resistance wire elements are versatile and are used in a wide array of applications, including toasters, hair dryers, industrial furnaces, and even snow melting systems.

Silicon Carbide Heating Elements

Silicon carbide (SiC) heating elements offer a higher temperature range, typically from 1300-1600°C. These elements are known for their durability and efficiency, making them suitable for high-temperature applications such as industrial furnaces and specialized laboratory equipment. Silicon carbide elements are often preferred in environments where prolonged exposure to high temperatures is required.

MoSi2 Heating Elements

Molybdenum disilicide (MoSi2) heating elements are designed for the highest temperature range among the three, operating between 1600-1800°C. These elements are ideal for applications that demand extreme temperatures, such as in the production of advanced materials like ceramics and composites. MoSi2 elements are also known for their resistance to oxidation and their ability to maintain structural integrity at very high temperatures.

In summary, the choice of heating element depends on the specific temperature requirements of the application. Resistance wire elements are suitable for moderate temperatures, silicon carbide for higher temperatures, and MoSi2 for the most extreme temperature needs. Each type offers unique advantages, ensuring that the laboratory tube furnace can be tailored to meet the specific needs of various experiments and processes.

Sample Size and Crucible Selection

Crucible Types and Usage

When selecting a crucible for your laboratory tube furnace, it's crucial to consider the maximum temperature your experiments will reach. Crucibles are typically made from materials that can withstand specific temperature ranges:

- Quartz Crucibles: Ideal for operations that require temperatures up to 1200°C. Quartz is a popular choice due to its transparency and resistance to thermal shock.

- Alumina Crucibles: Suitable for higher temperature applications, up to 1800°C. Alumina crucibles are known for their excellent thermal conductivity and durability.

- Graphite Crucibles: Designed for the most demanding applications, withstanding temperatures up to 2300°C. Graphite crucibles are often used in high-temperature metal processing due to their high thermal stability.

It's important to avoid placing samples directly into the furnace tube. Instead, use a crucible to protect both the sample and the furnace from contamination and damage. This practice ensures that the furnace tube remains intact and extends its operational life.

Additionally, the size and shape of the crucible can vary significantly depending on the application. Some crucibles are designed to be fixed within the furnace, while others are removable for pouring at the end of the process. The choice of crucible also depends on the specific performance characteristics required for your experiment, such as temperature resistance, chemical inertness, and physical robustness.

For instance, in scientific research where inert materials are necessary, crucibles made from platinum, zirconium, silicon carbide, and other specialized materials are used. These crucibles are designed to maintain their integrity under extreme conditions, ensuring accurate and reliable experimental results.

Tube Diameter Selection

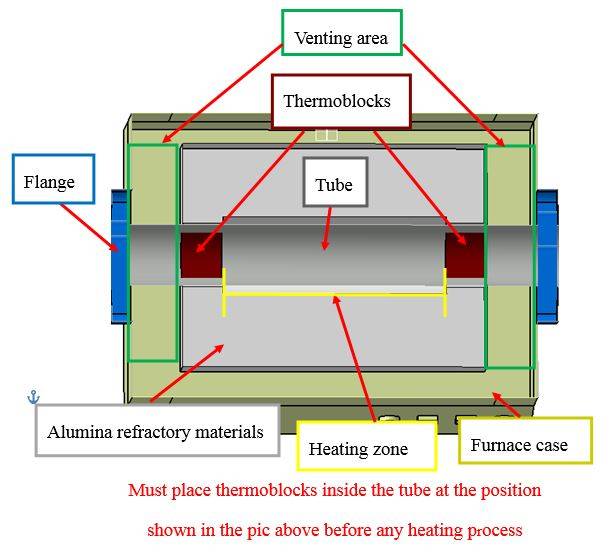

When selecting a furnace tube diameter, it is crucial to consider the volume of the crucible that will be used. The choice of tube material is also influenced by the maximum operating temperature required for your experiments.

For applications where the temperature does not exceed 1200°C, quartz tubes are the preferred choice. Quartz is known for its excellent thermal resistance and transparency, making it ideal for monitoring reactions through visual inspection.

On the other hand, for operations that demand temperatures up to 1800°C, corundum tubes (aluminum oxide) are recommended. Corundum offers superior thermal stability and resistance to thermal shock, ensuring reliable performance at higher temperatures.

It is important to note that the selection of tube material directly correlates with the crucible material. For instance, if you are using a quartz crucible, a quartz tube is the logical choice to prevent any chemical or thermal incompatibility. Similarly, alumina crucibles should be paired with corundum tubes to ensure optimal performance and longevity of your furnace setup.

Temperature Zone Selection

Role of Temperature Zones

When selecting a laboratory tube furnace, one of the critical decisions is whether to opt for a single-zone or multi-temperature zone furnace. Each type offers distinct advantages depending on your specific experimental needs.

Single-Zone Furnaces:

- Simplicity and Cost-Effectiveness: Ideal for basic heating applications where uniform temperature across the entire furnace is sufficient.

- Compact Design: Typically smaller and more portable, making them suitable for laboratories with limited space.

Multi-Temperature Zone Furnaces:

- Enhanced Control: Allow for different temperature settings in various zones, providing greater flexibility for complex experiments.

- Extended Thermostat Areas: These furnaces feature longer thermostat areas, enabling precise temperature control over larger sample sizes or multiple samples simultaneously.

- Larger Sizes: Often larger in physical dimensions, accommodating more extensive experimental setups and higher throughput.

The choice between single and multi-zone furnaces should be guided by the complexity of your experiments and the need for precise temperature control. Multi-zone furnaces, with their extended thermostat areas and larger sizes, are particularly advantageous for research requiring varied temperature conditions across different sections of the furnace.

Constant Temperature Zone

The constant temperature zone is a critical feature in laboratory tube furnaces, ensuring that the heating process is uniform and consistent. This zone is designed to maintain a stable temperature throughout the heating cycle, which is essential for precise experimental outcomes. The uniformity of temperature within this zone is crucial for experiments that require specific thermal conditions, such as those involving delicate materials or complex chemical reactions.

Adjusting the constant temperature zone can be tailored to meet the specific needs of different experiments. Factors such as sample size and the nature of the experiment play a significant role in determining the optimal settings for this zone. For instance, larger samples may require a broader constant temperature zone to ensure even heating across the entire sample, while smaller samples might necessitate a more focused heating area.

Moreover, the ability to adjust the constant temperature zone allows for greater flexibility in experimental design. Researchers can fine-tune the heating parameters to match the unique requirements of their experiments, thereby enhancing the accuracy and reliability of their results. This adaptability is particularly valuable in fields like material science and nanotechnology, where precise temperature control can significantly impact the properties and behavior of the materials being studied.

In summary, the constant temperature zone is not just a static feature but a dynamic component that can be adjusted to suit various experimental needs, ensuring optimal heating conditions for a wide range of applications.

Functional Requirements

Advanced Systems and Furnaces

When selecting advanced laboratory tube furnaces, a variety of specialized systems are available, each tailored to specific research and industrial needs. These options include graphene growth systems, which are designed for the precise synthesis of graphene layers, critical for applications in electronics and materials science. Vertical tube furnaces offer a compact design with efficient heat distribution, making them ideal for high-throughput applications. Rapid Thermal Processing (RTP) systems provide quick heating and cooling cycles, essential for processes requiring rapid thermal changes.

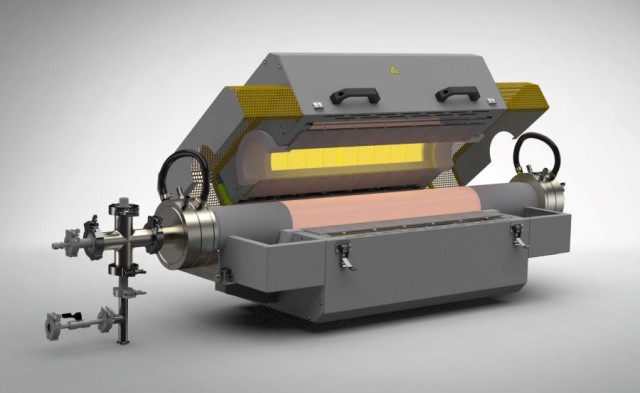

For applications demanding extreme conditions, high-temperature high-pressure furnaces are indispensable. These systems can operate at temperatures exceeding 2000°C and under high pressures, suitable for materials synthesis and high-stress testing. Rotary tube furnaces are engineered for continuous processing, ensuring uniform heating and mixing of materials during extended operations. Lastly, hydrogen/atmosphere furnaces are designed to control the atmosphere within the furnace, allowing for precise gas mixtures that are crucial for certain chemical reactions and material treatments.

Each of these advanced systems offers unique capabilities, enabling researchers and engineers to tailor their furnace selection to the specific demands of their experiments or production processes.

Related Products

- Multi-zone Laboratory Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vertical Laboratory Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

Related Articles

- Introducing the Lab Vacuum Tube Furnaces

- Comprehensive Guide to Tube Furnaces: Types, Applications, and Considerations

- Exploring the Key Characteristics of Tube Heating Furnaces

- Exploring the Using a Chamber Furnace for Industrial and Laboratory Applications

- Advanced Laboratory Furnaces: Box, Muffle, and Tube Options for High-Temperature Applications