Introduction to Muffle Furnace

Definition and Applications

A muffle furnace, often referred to as a high-temperature electric furnace, plays a crucial role in various laboratory processes. Its primary function is to facilitate the weighing analysis of scorching precipitation and the determination of ash content in samples. Beyond these core applications, muffle furnaces are also employed in a wide array of laboratory tasks that require precise temperature control and uniform heating.

The versatility of muffle furnaces is evident in their ability to handle different types of materials and samples. For instance, they are commonly used in the analysis of minerals, ceramics, and various organic materials. The high-temperature environment provided by these furnaces allows for the decomposition and transformation of materials, making them indispensable in research and quality control processes.

Moreover, muffle furnaces are designed to operate at temperatures ranging from 950°C to 1350°C, depending on the specific model and application. This broad temperature range ensures that they can cater to diverse experimental needs, from routine laboratory procedures to specialized research activities. The ability to maintain uniform heating across the furnace chamber is another key feature, ensuring consistent results and reliable data.

In summary, the muffle furnace's robust capabilities make it an essential tool in laboratory settings, supporting a variety of analytical and experimental processes with precision and efficiency.

Types and Specifications

Muffle furnaces are distinguished by their heating elements and operating temperatures, which range from 950°C to 1350°C. The primary heating elements include thermal wire and silicon-carbon rods, each offering unique advantages in terms of heating efficiency and durability.

Additionally, muffle furnaces can be classified into two main models based on their temperature control mechanisms:

- Fixed Temperature Rise Models: These furnaces operate at a constant, preset temperature, making them ideal for applications that require consistent heat levels.

- Program Temperature Rise Models: These models offer programmable temperature settings, allowing for precise control and gradual temperature increases, which is particularly useful for complex experiments requiring specific heating profiles.

This classification ensures that users can select a muffle furnace that best suits their specific laboratory needs, whether for routine tasks or more intricate procedures.

Structural Details

Furnace Chamber

The furnace chamber is constructed from a high-temperature-resistant silicon oxide bonded material, ensuring durability under extreme heat conditions. This material choice is crucial for maintaining structural integrity and preventing thermal degradation during prolonged high-temperature operations.

In addition to its robust material, the chamber features strategically placed grooves designed to accommodate furnace wires. These grooves are essential for achieving uniform heating throughout the chamber, which is vital for consistent experimental results. The arrangement of these grooves allows for optimal heat distribution, minimizing hotspots and ensuring even temperature across the entire working area.

Furthermore, the furnace chamber incorporates a double-wall, water-cooled design. This design includes an intermediary space between the walls that facilitates the circulation of coolant, providing additional thermal management and extending the lifespan of the chamber. Internal stiffeners are integrated between the walls to enhance the overall strength and stability of the chamber, ensuring it can withstand the mechanical stresses associated with high-temperature operations.

The chamber is also equipped with all necessary ports and entries, including thermocouple jacks, gauge ports, pumping ports, and gas quench entries. These features are thoughtfully positioned to ensure both functionality and ease of maintenance, allowing for seamless integration of temperature monitoring and gas management systems. This comprehensive setup ensures that the furnace chamber not only performs reliably but also remains accessible for routine maintenance and troubleshooting.

Heating Elements

Silicon-carbon rod type furnaces employ silicon-carbon rods as their primary heating elements, which are renowned for their ability to withstand high temperatures and maintain structural integrity. On the other hand, resistance wire type furnaces utilize nickel-chromium-nickel-aluminum thermocouples, which are equally effective but operate on a different principle. These thermocouples work by generating heat through the process of Joule heating, where electrical energy is converted into thermal energy due to the resistance encountered by the current flowing through the wire.

The choice between silicon-carbon rods and resistance wires often depends on the specific application and the required operating temperatures. For instance, nichrome, a common material in resistance wires, is particularly favored for its high resistance and the formation of a protective chromium oxide layer upon initial heating, which prevents further oxidation and extends the element's lifespan. The cross-sectional area of the heating element is also crucial; larger diameters generally indicate lower resistance, making them suitable for high-temperature applications, whereas smaller diameters are more appropriate for low-power devices like toasters and hair dryers.

In industrial settings, where furnaces like endo carburizing and vacuum furnaces (especially Low-Pressure Carburizing, LPC) are prevalent, the design and maintenance of heating elements are critical. These furnaces require elements that can endure rigorous conditions and maintain consistent performance, often necessitating elements with appropriate cross-sectional areas to ensure the required resistance and heat output.

Insulation and Observation

The outer layer of the furnace chamber is meticulously insulated with refractory materials, designed to minimize heat dissipation and maintain optimal internal temperatures. These materials, which can withstand extreme heat, are crucial in ensuring that the energy used for heating is efficiently retained within the chamber, thereby enhancing the furnace's overall performance and energy efficiency.

For temperature observation, the furnace door is equipped with a strategically placed small aperture covered by a thin mica sheet. This setup allows for real-time monitoring of the internal temperature without compromising the insulation integrity of the door. The use of mica, a material known for its excellent thermal resistance and transparency, ensures that the observer can accurately gauge the temperature inside the furnace while protecting the integrity of the insulation system.

This dual approach to insulation and observation is integral to the safe and efficient operation of the muffle furnace, providing both thermal stability and operational visibility.

Usage and Temperature Control

Temperature Control Mechanism

Temperature control in a muffle furnace is meticulously managed through a sophisticated system that includes a temperature controller, a millivoltmeter, and a relay. This system is intricately connected to a thermocouple, which plays a pivotal role in ensuring precise temperature monitoring and regulation.

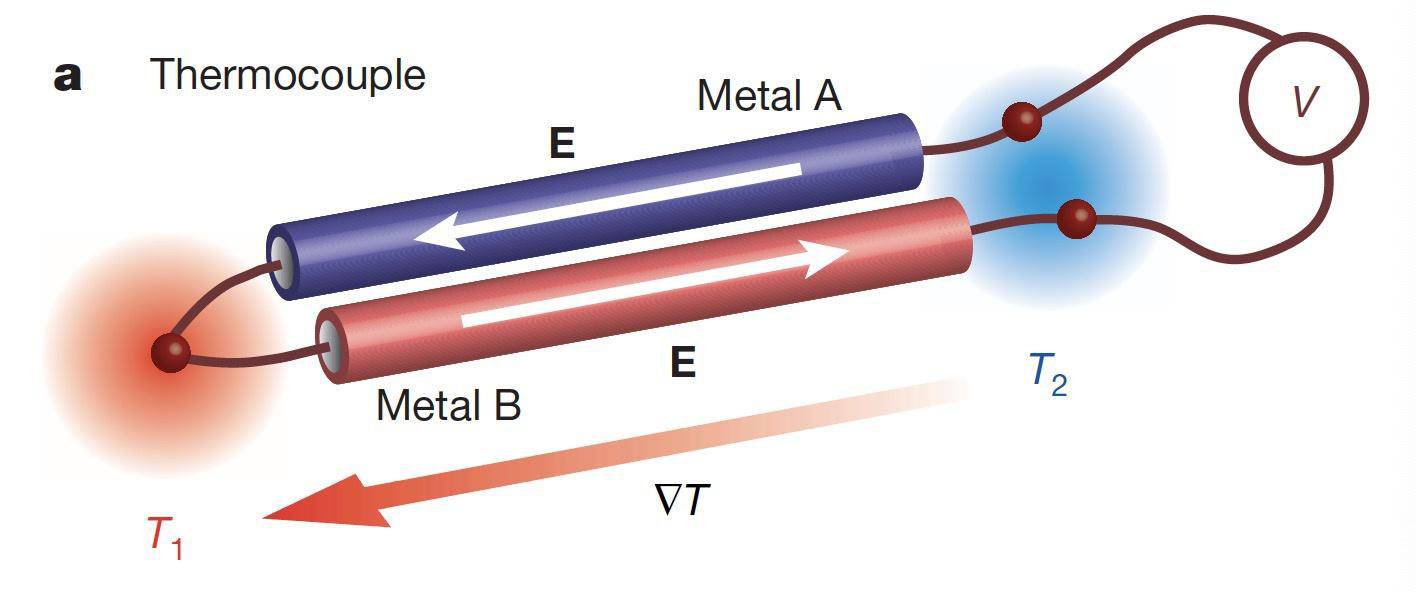

The thermocouple operates on the principle of electron diffusion between two dissimilar metals, generating a temperature-dependent electric potential. This potential is then measured by the millivoltmeter, providing real-time data to the temperature controller. The controller, in turn, adjusts the heating elements to maintain the desired temperature within the furnace chamber.

To enhance the accuracy and reliability of temperature control, the system employs a relay that acts as a switch, enabling or disabling the power supply to the heating elements based on the signals received from the temperature controller. This setup ensures that the temperature within the furnace remains stable and consistent, crucial for accurate laboratory analyses and experiments.

In summary, the temperature control mechanism in a muffle furnace is a blend of advanced electronics and precise thermal sensing, designed to deliver optimal performance and reliability in high-temperature environments.

Thermocouple Principle

Thermocouples operate based on the fundamental principle of Seebeck effect, which involves the diffusion of electrons between two dissimilar metals. When these metals are connected at one end and subjected to a temperature gradient, a continuous flow of electrons occurs, creating an electric potential difference. This phenomenon is often referred to as the thermoelectric effect.

The electric potential generated by the thermocouple is directly proportional to the temperature difference between the two junctions of the metals. This potential is typically measured in millivolts and is read using a specialized device known as a millivoltmeter. The millivoltmeter is calibrated to convert the measured voltage into a corresponding temperature value, providing precise temperature readings.

To better understand the process, consider the following steps:

- Metal Junctions: Two different metals, such as iron and constantan, are joined at one end to form a junction.

- Temperature Gradient: When the junction is exposed to a temperature difference, electrons from the metal with a higher electron density diffuse into the metal with a lower electron density.

- Electric Potential: This diffusion creates an electric potential difference across the two metals.

- Measurement: The resulting voltage is measured by a millivoltmeter, which then translates this voltage into a temperature reading.

This principle is crucial for the accurate temperature control in muffle furnaces, ensuring precise heating and consistent results in laboratory applications.

Safety Precautions

Placement and Wiring

The placement and wiring of a muffle furnace are critical steps that ensure both safety and optimal performance. The furnace should be situated on a robust, stable platform to prevent any accidental tipping or shifting, which could lead to potential hazards. This platform should be able to withstand the weight and thermal stresses of the furnace, ensuring that it remains securely in place during operation.

Proper wiring is equally essential. The thermocouple, which measures the temperature inside the furnace, must be correctly connected to the temperature controller. This connection is crucial as it allows the controller to regulate the furnace's temperature accurately. Incorrect wiring can result in unreliable temperature readings, leading to improper furnace operation and potential damage.

Additionally, the wiring should be checked and secured to prevent any loose connections that could cause electrical arcing or short circuits. Ensuring that all wiring is correctly routed and protected from heat and physical damage will help maintain the longevity and safety of the furnace. By adhering to these guidelines, users can ensure that their muffle furnace operates efficiently and safely, minimizing the risk of accidents and equipment failure.

Operational Safety

After completing the operation, it is crucial to immediately cut off the power supply to the muffle furnace. This precautionary measure prevents any residual heat from causing unintended reactions or damage. Additionally, the furnace door should not be opened immediately. The high temperature inside the furnace can cause rapid cooling, leading to thermal shock and potential damage to the hearth.

Regular monitoring and maintenance are indispensable for ensuring the longevity and efficiency of the muffle furnace. This includes periodic inspections of the heating elements, thermocouples, and temperature controllers. Any signs of wear or malfunction should be addressed promptly to prevent more significant issues down the line.

To further enhance operational safety, consider implementing a maintenance schedule that includes:

- Daily Checks: Ensure the furnace is operating within the specified temperature range.

- Weekly Inspections: Examine the condition of the heating elements and thermocouples.

- Monthly Maintenance: Clean the furnace chamber and check for any loose wiring or connections.

By adhering to these practices, you can significantly reduce the risk of operational failures and ensure the safe and efficient use of your muffle furnace.

Environmental Safety

Maintaining a clean furnace chamber is paramount to ensuring environmental safety. Any accumulation of dust or debris can significantly increase the risk of accidents, particularly when coupled with the high temperatures generated within the chamber. Therefore, regular cleaning protocols should be established to remove any potential contaminants.

Additionally, it is crucial to keep flammable substances at a safe distance from the muffle furnace. This precaution is not only about preventing immediate hazards but also about mitigating the long-term risks associated with prolonged exposure to flammable materials. A comprehensive safety checklist should include the prohibition of storing or using flammable liquids, gases, or solids in the vicinity of the furnace.

To further enhance environmental safety, consider implementing a routine inspection schedule. This should cover not only the furnace chamber but also the surrounding area. Use this opportunity to identify and address any potential hazards before they escalate into more serious issues. By adhering to these practices, laboratories can significantly reduce the likelihood of accidents and ensure a safer working environment.

Related Products

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1200℃ Muffle Furnace Oven for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

Related Articles

- Comprehensive Guide to Muffle Furnaces: Types, Uses, and Maintenance

- The Architecture of Emptiness: Mastering Material Selection in Vacuum Furnaces

- Why Your High-Temperature Experiments Fail: The Furnace Flaw Most Labs Overlook

- Muffle vs. Tube Furnace: How the Right Choice Prevents Catastrophic Lab Failure

- Box Furnace vs. Muffle Furnace: Are You Using the Wrong Tool for the Job?