Overview of Muffle Furnaces

Types and Uses

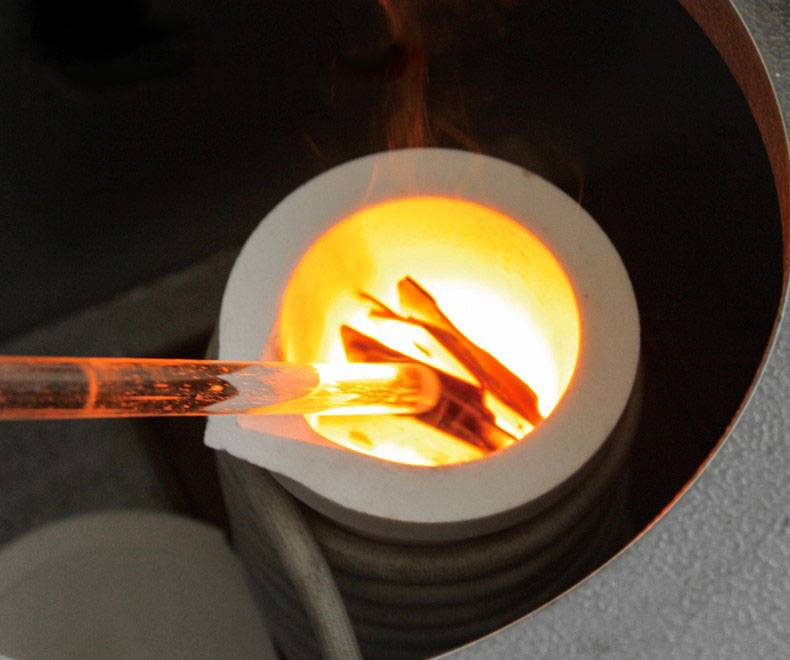

Muffle furnaces, often referred to as high-temperature ash furnaces, are highly versatile heating equipment that find applications across a spectrum of industries. These furnaces are indispensable in thermal processing, where they facilitate the controlled heating and cooling of materials to achieve specific physical and chemical transformations. In the pharmaceutical sector, muffle furnaces are used for processes such as sterilization and pyrolysis, ensuring the purity and efficacy of drugs.

In analytical chemistry, these furnaces play a crucial role in sample preparation, particularly in techniques like ashing, where organic materials are converted into inorganic residues for further analysis. For coal quality analysis, muffle furnaces are employed to determine the ash content and calorific value of coal samples, providing critical data for energy production and environmental assessments.

Metal sintering processes also benefit from muffle furnaces, which help in compacting metal powders into solid forms with enhanced mechanical properties. Similarly, heat treatment applications use these furnaces to alter the microstructure of metals, thereby improving their hardness, strength, and wear resistance.

In the realm of ceramic firing, muffle furnaces are essential for achieving the high temperatures required to vitrify ceramics, ensuring their durability and aesthetic qualities. Lastly, in experimental research, these furnaces offer a reliable means of conducting high-temperature experiments, supporting advancements in various scientific disciplines.

Performance Features

Muffle furnaces are designed to deliver a range of performance features that cater to diverse laboratory needs. These furnaces are capable of operating within an extensive temperature range, often surpassing 1000°C, making them suitable for high-temperature applications such as ceramic firing and metal sintering. The heating speeds of these furnaces are remarkably fast, allowing for rapid thermal processes that can significantly reduce experimental cycle times.

Precision temperature control is another critical feature, ensuring that the furnace can maintain exact temperatures, which is essential for experiments requiring high accuracy. This level of control is often achieved through advanced temperature control systems that offer precision within ±1°C or better, making them ideal for analytical chemistry and other sensitive applications.

The chamber volumes of muffle furnaces are customizable, enabling laboratories to select the appropriate size based on their specific needs. Whether handling small samples or large batches, the flexibility in chamber design ensures that the furnace can accommodate various experimental setups.

Some advanced models feature energy-saving ceramic fiber chambers, which not only enhance the furnace's efficiency but also contribute to its durability. These chambers are designed to retain heat more effectively, reducing energy consumption and extending the lifespan of the furnace. This combination of energy efficiency and durability makes ceramic fiber chambers a preferred choice for many laboratories.

Key Characteristics

Muffle furnaces are distinguished by several key characteristics that make them suitable for a variety of laboratory and industrial applications. These features not only enhance the functionality of the furnace but also ensure safety and efficiency in operation.

One of the standout features is the split design body, which allows for easier maintenance and repair. This design typically separates the heating chamber from the control panel, reducing the risk of electrical hazards and making it simpler to replace components like heating elements.

Intelligent controllers are another critical component, offering advanced automation and precision. These controllers can be programmed to manage complex heating cycles, ensuring that the furnace operates within the desired temperature range and duration. They often come with user-friendly interfaces, making it easy for even novice operators to set up and monitor the furnace.

The durable heating elements are essential for maintaining consistent performance over long periods. These elements, often made from high-quality materials like silicon carbide or molybdenum disilicide, can withstand high temperatures without degrading, ensuring reliable heating and extended furnace life.

Advanced temperature control systems provide precise regulation of the internal temperature. This is crucial for experiments that require exact temperature conditions, such as those in analytical chemistry or material science. Many modern furnaces offer temperature uniformity within ±1°C, which is vital for consistent results.

Safety is a paramount concern in laboratory settings, and muffle furnaces are equipped with several safety features. These can include automatic shut-off mechanisms, over-temperature alarms, and emergency stop buttons, ensuring that the furnace can be safely operated even in unsupervised conditions.

Finally, the ability to customize furnace chambers allows for flexibility in handling different types and sizes of samples. Whether you need a small chamber for routine analyses or a larger one for bulk processing, customizable options ensure that the furnace can be tailored to meet specific needs.

In summary, the combination of these characteristics makes muffle furnaces a versatile and reliable choice for a wide range of laboratory applications.

Selecting the Appropriate Muffle Furnace

Temperature Requirements

When selecting a muffle furnace, it is crucial to consider the temperature range required for your specific experiments. Different processes demand varying temperature extremes, and understanding these needs is essential for choosing the right equipment.

For instance, material drying typically necessitates moderate temperatures, generally ranging from 500 to 600°C. This range ensures that materials are dried efficiently without causing thermal degradation. On the other hand, ceramic firing processes often require much higher temperatures, sometimes reaching up to 1700°C. These elevated temperatures are necessary to achieve the desired structural and physical properties in ceramics.

| Process Type | Temperature Range | Importance of Temperature Control |

|---|---|---|

| Material Drying | 500-600°C | Ensures efficient drying without thermal degradation |

| Ceramic Firing | Up to 1700°C | Achieves desired structural and physical properties |

Understanding these temperature requirements helps in selecting a muffle furnace that can precisely meet the thermal needs of your experiments, ensuring optimal results and process efficiency.

Furnace Chamber Size

When selecting a muffle furnace, the size of the chamber is a critical consideration that directly impacts your experimental efficiency and results. The chamber size must be commensurate with the size and number of samples you intend to process. Larger samples, or a higher volume of samples, necessitate a larger furnace chamber to accommodate the necessary space for uniform heating and processing.

To determine the appropriate chamber size, begin by evaluating the dimensions of your typical samples. Consider whether these samples are standard or unusually large. For instance, if you frequently work with large ceramic pieces or multiple samples simultaneously, a larger chamber will be indispensable. Conversely, smaller chambers are suitable for more compact or individual samples, optimizing space and energy efficiency.

Another factor to consider is the volume of samples you process regularly. Higher throughput requirements may necessitate a larger chamber to avoid frequent reloading and to maintain continuous operation. This is particularly important in industries where batch processing is common, such as in pharmaceutical or analytical chemistry labs.

In summary, the choice of furnace chamber size should be guided by the specific needs of your laboratory. By carefully assessing the size and volume of your samples, you can select a muffle furnace with a chamber that ensures optimal performance and efficiency in your experiments.

Temperature Uniformity

For precise experiments, selecting a furnace with high temperature uniformity is crucial. This uniformity is typically measured by the variation in temperature across the hot zone, often expressed as a range (e.g., ±20°F). For instance, furnaces conforming to AMS 2750D, Class 4, offer a temperature uniformity of ±20°F within the range of 300-600°F. This level of precision ensures that all samples within the furnace chamber experience consistent heating, which is essential for reproducible results.

However, not all applications require such stringent uniformity. General material drying, for example, may not demand the same level of precision. In these cases, a furnace with broader temperature uniformity specifications might suffice, reducing costs without compromising the overall effectiveness of the process.

Temperature uniformity in a furnace is largely influenced by the design of the hot zone, including insulation and the arrangement of heating elements. Optimal uniformity is achieved through careful design that minimizes gaps and openings, particularly at critical points like gas exit ports. Additionally, a multi-zone heating system can help adjust power input dynamically, ensuring more uniform temperature distribution across the chamber.

| Temperature Range | Uniformity (±°F) | AMS 2750D Class |

|---|---|---|

| 300-600°F | 20 | Class 4 |

| 600-900°F | 15 | Class 3 |

| 900-2500°F | 10 | Class 2 |

Understanding these specifications can guide you in choosing the right furnace for your specific laboratory needs, balancing precision with practicality.

Rising Temperature Rate

When choosing a muffle furnace for your laboratory needs, the rising temperature rate is a critical factor to consider, especially for processes that require rapid thermal cycling. A furnace with a fast temperature rise rate can significantly reduce the time required to reach the desired operating temperature, thereby accelerating experimental timelines and improving overall efficiency.

For applications such as rapid sintering or quick heat treatments, a furnace capable of achieving high temperature gradients in a short period is indispensable. These rapid thermal processes demand equipment that can swiftly transition from ambient to operational temperatures, ensuring that the material properties are altered within the required timeframe.

However, it's important to note that not all laboratory processes necessitate a fast rising temperature rate. Routine sintering, for example, may not require this feature, as it often involves prolonged heating at a steady temperature. In such cases, a furnace with a more moderate temperature rise rate might suffice, balancing performance with cost-effectiveness.

| Process Type | Temperature Rise Rate Requirement |

|---|---|

| Rapid Thermal Processes | High (Fast temperature rise) |

| Routine Sintering | Moderate (Steady temperature rise) |

In summary, while a fast rising temperature rate can be a game-changer for certain laboratory applications, it is not universally essential. Careful consideration of your specific experimental needs will help you determine the optimal balance between speed and cost.

Control Precision

For experiments requiring exact temperature control, it is imperative to select furnaces with high precision, typically within ±1°C or better. This level of accuracy ensures that the thermal conditions remain consistent and within the desired parameters, which is crucial for experiments involving sensitive materials or precise chemical reactions.

| Precision Level | Typical Applications |

|---|---|

| ±1°C or better | Analytical chemistry, pharmaceutical research, and experimental studies requiring exact temperature control. |

| ±5°C or higher | General heating treatments, material drying, and routine sintering processes. |

In contrast, general heating treatments, such as material drying or routine sintering, may not necessitate such stringent precision. These processes often tolerate a broader range of temperature variability, making furnaces with less precise control sufficient for their needs. Therefore, the choice of furnace should align with the specific requirements of the experiment to ensure both efficiency and accuracy.

Furnace Material

When selecting a muffle furnace, the material of the hearth is a critical factor that directly influences the furnace's performance and longevity. The two primary materials used for hearths are ceramic fiber and refractory brick, each offering distinct advantages tailored to different applications.

Ceramic fiber hearths are renowned for their rapid heating capabilities and energy efficiency. These hearths are composed of lightweight, insulating materials that allow for quick temperature changes, making them ideal for processes that require frequent or rapid heating cycles. Their energy-efficient design helps in reducing operational costs, which is particularly beneficial for laboratories where energy consumption is a key concern.

On the other hand, refractory brick hearths are built to withstand extreme temperatures and are more durable for high-temperature applications. These hearths are constructed from materials that can endure prolonged exposure to high heat without degrading, making them suitable for operations that demand continuous high-temperature processing, such as ceramic firing or metal sintering. While they may take longer to heat up compared to ceramic fiber hearths, their superior durability ensures a longer service life and consistent performance under demanding conditions.

Choosing between these materials depends on the specific requirements of your laboratory processes. For experiments that necessitate quick heating and energy efficiency, ceramic fiber hearths are the preferred choice. However, for applications that involve continuous high-temperature operations, refractory brick hearths offer the necessary robustness and reliability.

Additional Features

When selecting a muffle furnace, it's crucial to consider features that can enhance the functionality and efficiency of your experiments. Programmable controls are particularly beneficial for experiments requiring precise, multi-stage heat treatments. These controls allow for the customization of heating profiles, ensuring that each stage of the process is executed accurately and consistently.

Automatic alarms are another essential feature, providing real-time notifications for critical events such as reaching a specific temperature, power fluctuations, or system malfunctions. This ensures that you can promptly address any issues, minimizing the risk of experimental errors or equipment damage.

For experiments involving sensitive materials or time-critical processes, features like remote monitoring and data logging can be invaluable. These capabilities allow you to track and record temperature data over time, providing valuable insights into the performance of your furnace and the outcomes of your experiments.

Additionally, consider furnaces equipped with energy-saving technologies such as ceramic fiber chambers, which offer faster heating times and lower energy consumption compared to traditional refractory brick hearths. These features not only reduce operational costs but also contribute to a more sustainable laboratory environment.

By carefully evaluating these additional features, you can select a muffle furnace that not only meets your experimental needs but also enhances the overall efficiency and effectiveness of your laboratory work.

Related Products

- 1200℃ Muffle Furnace Oven for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- Engineering Advanced Fine Alumina Al2O3 Ceramic Crucible for Laboratory Muffle Furnace

Related Articles

- The Ultimate Guide to Choosing the Right Lab Furnace for Your Needs

- How to Choose the Best Porcelain Furnace Dental

- Comparing Laboratory Furnace Features and Specifications: A Guide

- Exploring the Using a Chamber Furnace for Industrial and Laboratory Applications

- Comprehensive Guide to Muffle Furnaces: Applications, Types, and Maintenance