Introduction to Muffle Furnaces

Muffle furnaces are essential tools in both laboratory and industrial settings, playing a crucial role in high-temperature processes. This comprehensive guide delves into the intricacies of muffle furnaces, starting with an overview of their basic components and significance. We will explore their historical development, the various types available, and their applications across different industries. Additionally, this guide will provide essential maintenance tips and insights into future technological advancements, ensuring you have all the information needed to optimize the performance of your muffle furnace.

Historical Development of Muffle Furnaces

The evolution of muffle furnaces has been a testament to human ingenuity and technological advancement, particularly in the realms of material science and industrial processes. Originally, these furnaces were designed to isolate the material being heated from the fuel and combustion byproducts, ensuring a cleaner and more controlled heating environment. This concept has remained central to the design and function of muffle furnaces, even as they have evolved over the decades.

Early Developments

The early 20th century saw the initial designs of muffle furnaces, which primarily used coal and wood as heating sources. These furnaces were characterized by their distinct heating chambers and combustion processes, which were crucial for tasks such as melting metals and ceramics. The isolation of the material from the fuel was a significant innovation, reducing contamination and improving the quality of the end product.

Technological Advancements Post-World War II

The period following World War II marked a significant turning point for muffle furnaces. With the urgent need for economic recovery and development, industries such as manufacturing, agriculture, and chemistry began to heavily rely on high-temperature processing equipment. This demand spurred the development of more sophisticated muffle furnaces, including those that could operate at higher temperatures and with greater precision.

By the 1970s and 1980s, the integration of temperature and humidity sensors, along with the development of advanced temperature control instrumentation, provided the technical foundation for more efficient and accurate muffle furnaces. These advancements allowed for better control over the heating process, ensuring that materials were processed under optimal conditions.

Transition to Electric Muffle Furnaces

The widespread electrification in developed countries during the mid-20th century led to a shift from traditional fuel-based muffle furnaces to electric designs. Electric muffle furnaces offered several advantages, including cleaner operation, more precise temperature control, and greater energy efficiency. This transition was facilitated by the development of high-temperature heating elements, which could withstand the rigorous demands of industrial and laboratory applications.

Modern Applications and Innovations

Today, muffle furnaces are used in a wide range of applications, from creating enamel coatings and melting glass to conducting research in chemistry and material science. Modern muffle furnaces are equipped with advanced features such as digital temperature controls, programmable settings, and automated operations, making them indispensable tools in both industrial and academic settings.

In research laboratories, muffle furnaces are used to determine the total percentage of non-combustible and non-volatile components in samples, a critical analysis for various scientific studies. The ability to maintain high temperatures consistently and accurately is crucial for these applications, ensuring reliable and reproducible results.

Conclusion

The historical development of muffle furnaces reflects the continuous pursuit of technological innovation and efficiency. From their early designs using coal and wood to the sophisticated electric models of today, muffle furnaces have played a pivotal role in advancing various industries and scientific fields. As technology continues to evolve, it is likely that muffle furnaces will incorporate even more advanced features, further enhancing their capabilities and applications.

Types of Muffle Furnaces

Muffle furnaces are essential tools in various industries and laboratories, used for processes such as melting, drying, molding, and heating materials. These furnaces are designed to operate under controlled conditions, ensuring minimal contamination and precise temperature control. Here, we explore the different types of muffle furnaces available, highlighting their unique features and applications.

Electric Resistance Muffle Furnaces

Electric resistance muffle furnaces are the most common type, utilizing electric heating elements made of resistance wire, such as Nichrome. These furnaces can reach temperatures ranging from several hundred degrees Celsius to as high as 1800°C. They are widely used in laboratories for tasks like sintering, binder burnout, and melting, due to their ability to maintain precise and uniform temperatures.

High-Temperature Muffle Furnaces

High-temperature muffle furnaces are designed for applications requiring extreme heat, often used in material analysis and decomposition. These furnaces are constructed with high-grade components and materials, ensuring durability and excellent temperature control. The inner housing is typically made from double-walled stainless steel, which minimizes heat loss, while ceramic fiber insulation in the outer structure enhances heat radiation across the entire unit, promoting uniform heat distribution.

Split Furnace

Split furnaces feature a removable muffle chamber, which can be easily detached for cleaning or maintenance. This design is particularly beneficial in scenarios where the muffle may become contaminated or damaged over time. The ease of access allows for quick and efficient servicing, making split furnaces ideal for laboratories and industries where frequent maintenance is required.

Vacuum Furnace

Vacuum furnaces are engineered to heat materials in a vacuum or low-pressure environment. This feature is crucial for high-temperature processes that demand minimal contamination and precise temperature control. Vacuum furnaces are often used in advanced material processing, such as in the synthesis of high-performance alloys and ceramics, where the absence of atmospheric gases is essential to prevent oxidation and other chemical reactions.

Multi-Zone Furnace

Multi-zone furnaces are equipped with multiple heating zones, each capable of independent temperature control. This design allows for precise temperature management across different areas of the muffle, making them suitable for complex applications such as crystal growth and materials synthesis. The ability to maintain varying temperatures within a single furnace enhances its versatility and efficiency in research and industrial settings.

Laboratory Muffle Furnace

Laboratory muffle furnaces are specifically designed for experimental purposes, enabling the creation of specified temperatures for various heating tasks like melting and sintering. These furnaces are essential in research environments where controlled heating conditions are paramount for accurate and reliable results.

Electric Muffle Furnace

Electric muffle furnaces are renowned for their ability to operate at higher temperatures compared to other types, with higher power densities. They are used for a range of processes including drying, melting, heating, and molding of materials. Their robust performance and high-temperature capabilities make them a preferred choice in industries requiring intensive heating applications.

In conclusion, the selection of a muffle furnace depends on the specific requirements of the application, including temperature range, heating time, and material compatibility. Each type of furnace offers unique advantages, and careful consideration should be given to these factors to ensure the most effective and efficient operation in diverse industrial and laboratory settings.

Key Components of Muffle Furnaces

Muffle furnaces are essential equipment in laboratories for high-temperature processes such as ashing, annealing, and sintering. Understanding the key components of these furnaces is crucial for their effective operation and maintenance. This section delves into the essential components of muffle furnaces, including heating elements, refractory materials, and temperature control systems.

Heating Elements

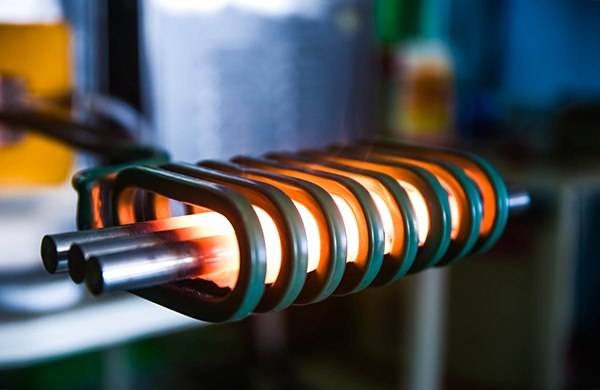

Heating elements are the core of any muffle furnace, responsible for generating the necessary heat. These elements are typically made from resistance wire or ceramic materials, which can withstand high temperatures without degrading. The choice of material for the heating elements depends on the maximum operating temperature of the furnace. For instance, nickel-chromium (Nichrome) wires are commonly used for furnaces operating up to 1100°C, while molybdenum disilicide elements are suitable for higher temperatures up to 1800°C.

The design and placement of heating elements are critical for uniform heat distribution within the muffle chamber. In many modern furnaces, the heating elements are wrapped around the refractory chamber or placed at strategic points to ensure even heating of the samples.

Refractory Materials

Refractory materials form the inner lining of the muffle chamber and are essential for insulating the furnace and protecting the outer casing from high temperatures. These materials must have high thermal resistance and low thermal conductivity to maintain a constant temperature inside the furnace. Common refractory materials include ceramic tiles, zirconia boards, and high alumina bricks, which can withstand temperatures up to 1800°C.

The refractory lining also plays a crucial role in preventing direct contact between the heating elements and the samples, which could lead to contamination or uneven heating. The thickness and quality of the refractory lining are critical for the longevity and performance of the furnace.

Temperature Control Systems

Temperature control systems are vital for ensuring that the muffle furnace operates within the desired temperature range. Modern muffle furnaces are equipped with advanced digital controllers that allow users to set and maintain specific temperature levels accurately. These controllers utilize thermocouples or thermistors to monitor the internal temperature of the furnace and provide real-time feedback for precise adjustments.

Thermocouples are temperature sensors that generate a voltage proportional to the temperature difference between two points. They are widely used in muffle furnaces due to their accuracy and reliability. Thermocouples are typically made from alloys such as chromel-alumel or iron-constantan and can measure temperatures up to 1400°C.

Digital controllers also include safety features such as over-temperature alarms and automatic shut-off mechanisms to prevent overheating and potential damage to the furnace or samples. These features ensure the safe and efficient operation of the muffle furnace.

Power Supply and Insulation

The power supply is another critical component of a muffle furnace, providing the electrical energy needed to operate the heating elements. The power supply must be capable of delivering the required voltage and current to the heating elements without causing electrical stress or overheating.

Insulation materials surround the muffle chamber to help maintain a constant temperature inside the furnace. These materials, such as ceramic fibers or mineral wool, have low thermal conductivity and high thermal resistance, ensuring that heat is retained within the chamber and minimizing energy loss.

Outer Casing and Exhaust System

The outer casing of a muffle furnace is typically made from steel or other materials that provide structural strength and protect the internal components from physical damage and environmental factors. The casing also serves as a barrier against heat and radiation, ensuring the safety of the operators.

Some muffle furnaces include an exhaust system to vent gases or fumes generated during high-temperature processes. The exhaust system typically consists of a flue, exhaust duct, and a fan or blower to remove harmful emissions from the furnace chamber.

Conclusion

In conclusion, the key components of muffle furnaces, including heating elements, refractory materials, and temperature control systems, are essential for their effective operation and performance. Understanding these components and their functions is crucial for maintaining and optimizing the efficiency and safety of muffle furnaces in laboratory settings. By ensuring that these components are properly designed and maintained, laboratories can achieve reliable and accurate high-temperature processing for a wide range of applications.

Applications of Muffle Furnaces

Muffle furnaces are versatile high-temperature ovens used across a broad spectrum of industries and processes. Their primary function is to heat materials to extremely high temperatures while maintaining a controlled and isolated environment, which prevents external contaminants from affecting the process. This section delves into the various applications of muffle furnaces, highlighting their significance in laboratory research, metalworking, glass manufacturing, and several other industries.

Laboratory Research

In laboratory settings, muffle furnaces are indispensable for a variety of analytical procedures. They are commonly used for determining the ash content of samples, which is crucial in fields such as environmental science, materials testing, and forensic analysis. The precise temperature control and isolation provided by muffle furnaces ensure accurate and repeatable results, making them a standard piece of equipment in quality control and research laboratories.

Metalworking

In the metalworking industry, muffle furnaces play a critical role in processes such as annealing, hardening, and sintering. These processes require precise temperature management to achieve the desired metallurgical properties in the metal. Muffle furnaces are designed to maintain uniform temperatures within their chambers, ensuring that the metal is heated evenly and consistently. This uniformity is essential for preventing distortions and ensuring the structural integrity of the final product.

Glass Manufacturing

Glass manufacturing is another sector where muffle furnaces are extensively utilized. These furnaces are used for annealing glass, a process that relieves internal stresses and improves the durability of the glass. The controlled heating and cooling cycles provided by muffle furnaces are crucial for achieving the desired optical and mechanical properties in the glass. Additionally, muffle furnaces are used in the production of specialty glasses, where precise temperature control is necessary to achieve specific compositions and properties.

Other Industries

Beyond the laboratory, metalworking, and glass industries, muffle furnaces find applications in numerous other sectors:

- Ceramics Industry: Used for firing and sintering ceramic materials, which require high temperatures to achieve the desired hardness and durability.

- Biomedical Industry: Employed in the sterilization of medical instruments and the processing of biomaterials.

- Paint and Coating Industry: Used for curing and drying paint and coatings, ensuring uniform application and adherence.

- Plastics and Rubber Industry: Essential for processes like vulcanization and polymerization, which require high temperatures to alter the properties of plastics and rubber.

Factors to Consider When Choosing a Muffle Furnace

Selecting the right muffle furnace for a specific application involves considering several key factors:

- Temperature Range: The furnace should be capable of reaching and maintaining the required temperature for the intended process.

- Chamber Size: The internal volume of the furnace should be adequate to accommodate the samples or materials being processed.

- Heating and Cooling Rates: The speed at which the furnace can heat up and cool down can impact the efficiency and effectiveness of the process.

- Energy Efficiency: A furnace that is energy-efficient will reduce operational costs and environmental impact.

- Safety Features: Features such as automatic shut-off, over-temperature protection, and safe handling mechanisms are important for ensuring safe operation.

In conclusion, muffle furnaces are critical tools in a wide array of industries, offering precise temperature control and isolation necessary for high-temperature processes. Whether in laboratory research, metalworking, glass manufacturing, or other specialized industries, the functionality and reliability of muffle furnaces ensure that they remain an essential piece of equipment in modern industrial processes.

Advantages of Using Muffle Furnaces

Muffle furnaces are highly regarded in both laboratory and industrial settings for their efficiency, temperature uniformity, and cost-effectiveness. These furnaces are designed to reach extremely high temperatures, often up to 1800°C or higher, making them indispensable for processing materials that require such extreme conditions, including ceramics, metals, and minerals.

Efficiency and Versatility

One of the primary advantages of muffle furnaces is their versatility. They can be utilized for a wide range of applications such as annealing, hardening, tempering, calcination, and firing. This versatility makes them a crucial tool across various industries, including materials science, metallurgy, and ceramics. Moreover, muffle furnaces are known for their energy efficiency. They can operate on multiple power sources, including electricity and gas, which helps in reducing both operating costs and energy consumption.

Temperature Uniformity and Control

Muffle furnaces excel in providing precise temperature control and uniform heating. This is crucial for processes that require consistent heat distribution to ensure the quality and integrity of the materials being processed. The design of muffle furnaces allows for a controlled atmosphere, which protects samples from contamination and reduces issues like oxidation and carbonization. This level of control is essential for maintaining the purity and structural integrity of the materials.

Ease of Use and Safety

Another significant advantage of muffle furnaces is their ease of use. They typically come with simple controls and can be programmed to follow specific temperature and time profiles, requiring minimal operator training. This simplicity not only enhances productivity but also reduces the risk of errors. Additionally, muffle furnaces are designed with safety in mind, featuring robust structures that ensure durability and safety during operation.

Environmental and Cost Benefits

From an environmental perspective, muffle furnaces contribute to lower energy consumption and reduced emissions, making them a more sustainable option compared to other heating methods. Economically, the initial investment in a muffle furnace can be offset by its long-term cost-effectiveness, thanks to its energy efficiency and durability.

Conclusion

In summary, muffle furnaces offer numerous benefits that make them a preferred choice in many high-temperature processing applications. Their ability to provide uniform heating, precise temperature control, and a controlled atmosphere, combined with their energy efficiency and ease of use, positions them as a valuable and indispensable tool in both research and industrial settings. Whether for laboratory tests involving calcination, incineration, ceramic firing, or sterilization, muffle furnaces consistently demonstrate their superiority and reliability.

Maintenance and Troubleshooting of Muffle Furnaces

Muffle furnaces are essential tools in laboratories for high-temperature processes such as calcination, drying, and sintering. Proper maintenance and timely troubleshooting of common issues are crucial for ensuring their longevity and optimal performance. This section provides comprehensive guidelines on maintaining muffle furnaces and resolving typical problems.

Routine Maintenance Precautions

-

Initial and Periodic Baking: The first use or after long periods of disuse requires baking the furnace at 200°C to 600°C for four hours. This step prevents moisture from damaging the heating elements. During operation, the furnace temperature should not exceed its rated maximum to avoid burning the heating elements.

-

Environmental Conditions: The furnace and its controller should be located in an area with a relative humidity not exceeding 85%, free from conductive dust, explosive, or corrosive gases. Heating materials with volatile gases, such as greases, can corrode the heating elements, necessitating proper sealing or ventilation.

-

Thermocouple Management: Regular checks should ensure the wiring connections to the controller are secure. Thermocouples connected to the controller can cause interference, leading to erratic display values and increased measurement errors, especially at higher temperatures. Grounding the thermocouple metal protection tube or using a three-wire output thermocouple can mitigate these issues.

-

Temperature and Safety: The controller should operate within an ambient temperature range of 0°C to 40°C. Avoid sudden removal of thermocouples at high temperatures to prevent damage. Regularly clean the furnace chamber to remove oxides and other residues.

-

Handling Alkaline Substances: When using alkaline substances to melt specimens or incinerate sediments, control operating conditions strictly. Paving a layer of refractory material at the furnace bottom can prevent chamber corrosion.

Common Failures and Solutions

-

Heating Failure: This can be due to damaged heating elements or circuit issues. Solutions include checking and replacing damaged elements or repairing circuits.

-

Unstable Temperature: Causes may include temperature controller malfunctions or thermocouple damage. Calibrating or replacing the temperature controller and ensuring the thermocouple is functioning correctly can resolve this issue.

-

Inability to Reach Set Temperature: This might be due to power supply problems or poor furnace chamber sealing. Ensuring a stable power supply and checking the sealing condition of the furnace can help.

-

Furnace Door Sealing: If the door seal is not tight, it might be due to aging or damage of the sealing strip. Replacing the sealing strip is the solution.

-

Control System Failure: Circuit problems or controller malfunctions can cause this. Checking the circuit and repairing or replacing the controller is necessary.

-

Overheating Phenomenon: This could be due to a thermostat failure. Checking and replacing the thermostat if necessary is the remedy.

-

Leakage Problem: Insulation damage can lead to leaks. Checking the insulation and repairing or replacing damaged parts is crucial.

-

Abnormal Display: A malfunctioning display meter can cause this. Replacing the display meter is the solution.

-

Shell Overheating: This is often due to insulation failure. Replacing the insulation material can prevent this issue.

-

Excessive Noise: Loose mechanical parts or component failures can cause noise. Checking and tightening mechanical parts or replacing faulty parts can reduce noise.

In case of malfunctions, consulting the equipment’s instruction manual and following the appropriate operation and maintenance guidelines is recommended. If issues persist, contacting service personnel for professional assistance is advisable.

Regular Maintenance

Regular maintenance includes cleaning the muffle chamber and replacing damaged or worn-out components. This practice extends the furnace’s lifespan and ensures accurate and consistent results.

Safety Measures

When operating a muffle furnace, always wear appropriate personal protective equipment (PPE), including heat-resistant gloves and eye protection. Keep a fire extinguisher nearby and be aware of emergency procedures in case of accidents.

By adhering to these maintenance and troubleshooting guidelines, laboratories can ensure their muffle furnaces operate efficiently and safely, providing reliable results for various high-temperature applications.

Future Trends in Muffle Furnace Technology

The field of muffle furnace technology is poised for significant advancements, driven by the need for more efficient, reliable, and intelligent equipment. As industries ranging from pharmaceuticals to materials science continue to evolve, the demand for muffle furnaces that can meet these changing needs is increasing. Here, we explore the upcoming trends and innovations in muffle furnace technology, focusing on energy-saving features, smart controls, and enhanced performance.

Energy-Saving Features

One of the most critical areas of development in muffle furnace technology is energy efficiency. Traditional muffle furnaces can be energy-intensive, which not only increases operational costs but also contributes to environmental impact. Future muffle furnaces are expected to incorporate advanced insulation materials and heating elements designed to reduce energy consumption without compromising performance.

For instance, the use of ceramic fiber modules instead of traditional refractory bricks can significantly reduce heat loss. These modules have higher thermal efficiency and can withstand high temperatures, making them ideal for muffle furnace applications. Additionally, improved temperature control systems can ensure that the furnace operates at the optimal temperature, minimizing energy wastage.

Smart Controls and Automation

The integration of smart controls and automation is another significant trend in muffle furnace technology. Modern muffle furnaces are increasingly equipped with programmable logic controllers (PLCs) and touchscreen interfaces, allowing for precise control over temperature, time, and other operational parameters. These features not only enhance the accuracy and repeatability of experiments but also reduce the likelihood of human error.

Moreover, the advent of the Internet of Things (IoT) is enabling muffle furnaces to be connected to networks, allowing for remote monitoring and control. This capability is particularly beneficial in industries where continuous monitoring is crucial, such as in pharmaceutical and chemical manufacturing. Remote access also facilitates predictive maintenance, where potential issues can be identified and addressed before they lead to downtime.

Enhanced Performance and Versatility

Future muffle furnaces are also expected to offer enhanced performance and versatility. This includes the ability to operate at higher temperatures, faster heating and cooling rates, and improved temperature uniformity. These improvements are crucial for applications that require precise temperature control, such as in the synthesis of advanced materials or in analytical chemistry.

In addition to performance enhancements, muffle furnaces are likely to become more versatile, catering to a wider range of applications. For example, modular designs that allow for easy customization and expansion can enable users to adapt their furnaces to different experimental needs. This flexibility can be particularly beneficial in research environments where the requirements can vary significantly.

Environmental and Safety Considerations

As environmental regulations become more stringent, muffle furnace manufacturers are focusing on designing equipment that minimizes environmental impact. This includes the use of eco-friendly materials and the reduction of emissions. Additionally, safety features are being enhanced to ensure that muffle furnaces can be operated safely in various environments.

Advanced safety features may include automatic shut-off mechanisms in case of overheating, interlocks to prevent unauthorized access, and alarms for detecting gas leaks or other hazards. These enhancements not only protect users but also ensure compliance with safety standards, which is critical for industries such as pharmaceuticals and food processing.

Conclusion

The future of muffle furnace technology is bright, with significant advancements expected in energy efficiency, smart controls, performance, and safety. These innovations will not only enhance the capabilities of muffle furnaces but also make them more accessible and user-friendly. As industries continue to evolve, the demand for advanced muffle furnaces that can meet these changing needs will undoubtedly drive further innovation in this field. By staying abreast of these trends, users can ensure that they are equipped with the most efficient and effective muffle furnaces for their applications.

Related Products

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1200℃ Muffle Furnace Oven for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- Molybdenum Vacuum Heat Treat Furnace

Related Articles

- The Architecture of Emptiness: Mastering Material Selection in Vacuum Furnaces

- Why Your High-Temperature Experiments Fail: It's Not the Heat, It's the Furnace

- Comprehensive Guide to Muffle Furnaces: Types, Uses, and Maintenance

- Why Your Furnace Experiments Fail: The Hidden Mismatch in Your Lab

- Why Your Ashing Tests Fail: The Hidden Difference Between Muffle and Ashing Furnaces