Understanding Chamber Atmosphere Furnaces

Applications of Chamber Atmosphere Furnaces

Chamber atmosphere furnaces are indispensable tools in high-temperature processing, offering precise control over the environment within the furnace chamber. This precision is crucial for several critical applications across diverse industries.

In the realm of metallurgy, these furnaces are extensively used for annealing, tempering, and hardening metals. By meticulously controlling the atmosphere, they can eliminate impurities, enhance mechanical properties, and significantly improve the overall quality of metal components. This makes them vital for producing high-strength alloys and ensuring the durability of industrial machinery.

In the ceramics industry, chamber atmosphere furnaces play a pivotal role in the preparation of microcrystalline ceramic glazes. The controlled atmosphere allows for the precise manipulation of chemical reactions, resulting in ceramics with superior optical and mechanical properties. Additionally, these furnaces are essential for mold annealing, ensuring that ceramic molds maintain their structural integrity and precision.

The electronics industry also benefits from the use of chamber atmosphere furnaces, particularly in the sintering of metal powders. This process is crucial for creating intricate electronic components with high precision and reliability. The ability to control the atmosphere within the furnace ensures that the sintering process occurs uniformly, leading to components with consistent electrical properties.

Moreover, these furnaces are increasingly being utilized in the development of new materials. The ability to create and maintain specific atmospheres allows for the exploration of novel material properties and the synthesis of advanced composites. This has opened new avenues in material science, enabling the creation of materials with unique properties for various applications, from aerospace to biomedical devices.

In summary, chamber atmosphere furnaces are versatile tools that find applications in a wide range of industries, each benefiting from the precise control over high-temperature processes that these furnaces provide.

The Need for Atmosphere Furnace Gas Monitoring

Ensuring Furnace Tightness

To maintain precise control over the furnace atmosphere and ensure consistent pressure, it is imperative that the furnace is tightly sealed. A well-sealed furnace prevents atmospheric gases from leaking in or out, thereby maintaining the integrity of the controlled environment necessary for high-temperature processes such as precision annealing, ceramic glaze preparation, and powder sintering.

Gas analysis systems play a critical role in monitoring the tightness of the furnace. These systems continuously measure the concentration of various gases within the furnace, providing real-time data that helps operators to detect any leaks promptly. By ensuring the furnace remains tightly sealed, these systems contribute to the overall efficiency and safety of the production process.

In addition to preventing leaks, a tightly sealed furnace also helps in maintaining the desired carbon potential within the chamber. This is particularly important in processes that require specific atmospheric conditions, such as those in metallurgy and new material development. The use of gas analysis systems not only ensures the furnace's tightness but also supports the continuous adjustment of gas mixtures, thereby maintaining the stability of the furnace atmosphere.

Furthermore, maintaining furnace tightness is a key aspect of explosion prevention. By ensuring that the gas and air mixtures remain within safe ratios, operators can mitigate the risk of explosions during furnace operations. This proactive approach to safety underscores the importance of regular gas monitoring and the meticulous sealing of the furnace.

Maintaining Carbon Potential

Maintaining a specific carbon potential within the furnace atmosphere is crucial for ensuring the desired metallurgical outcomes in high-temperature processes. This involves meticulously controlling the stability of the furnace atmosphere and employing a suite of sophisticated control instruments to manage the gas supply. These instruments are designed to make continuous or periodic adjustments to the gas mixture, thereby maintaining the optimal carbon potential.

To achieve this, precise monitoring systems are integrated into the furnace setup. These systems continuously analyze the gas composition, ensuring that the atmosphere remains consistent and within the desired parameters. For instance, in processes like carburizing or carbonitriding, maintaining the correct carbon potential is essential to achieve the required surface hardness and depth of the carburized layer.

Moreover, the use of advanced control algorithms and automated feedback mechanisms allows for real-time adjustments. This not only enhances the efficiency of the process but also minimizes the risk of deviations that could compromise the quality of the final product. By leveraging these technologies, manufacturers can ensure that their high-temperature processes are both reliable and reproducible, meeting the stringent requirements of various industries such as automotive, aerospace, and tooling.

Explosion Prevention Measures

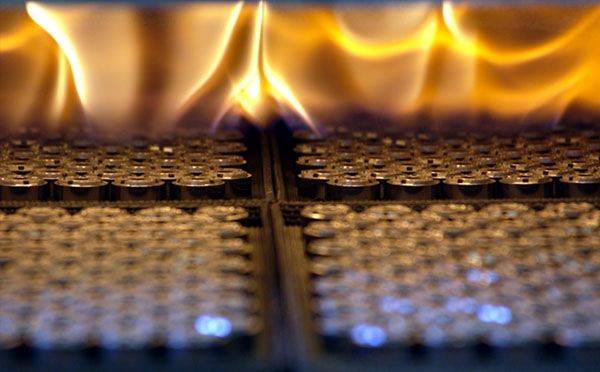

Reducing the concentration of gas and air mixtures to a safe ratio is a critical step in preventing explosions within chamber atmosphere furnaces. This is particularly vital during high-temperature processes such as precision annealing, microcrystalline ceramic glaze preparation, and powder sintering. The presence of flammable gases in the furnace atmosphere can lead to catastrophic consequences if not properly managed.

Gas monitoring plays a pivotal role in ensuring the safety of these processes. Advanced gas analysis systems continuously track the concentration of flammable gases, providing real-time data that operators can use to adjust the furnace atmosphere promptly. By maintaining a vigilant watch over gas levels, operators can take necessary explosion-proof measures to mitigate risks.

For instance, if the gas monitoring system detects an elevated concentration of a flammable gas, immediate actions such as adjusting the furnace pressure or introducing inert gases can be taken to dilute the mixture and bring it within safe limits. This proactive approach not only prevents potential explosions but also ensures the integrity and efficiency of the furnace operations.

In summary, the integration of robust gas monitoring systems with timely intervention strategies is essential for the safe and effective operation of chamber atmosphere furnaces. This dual approach ensures that the furnace environment remains within the safe operating parameters, safeguarding both the equipment and the personnel involved in the processes.

Related Products

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- Controlled Nitrogen Inert Hydrogen Atmosphere Furnace

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

Related Articles

- The Benefits of Controlled Atmosphere Furnaces for Sintering and Annealing Processes

- Comprehensive Guide to Atmosphere Furnaces: Types, Applications, and Benefits

- Muffle Furnace: Unraveling the Secrets of Uniform Heating and Controlled Atmosphere

- How Controlled Atmosphere Furnaces Improve Quality and Consistency in Heat Treatment

- Atmosphere Furnaces: Comprehensive Guide to Controlled Heat Treatment