Water Circulating Vacuum Pumps: Beyond the Basic Definition

Water circulating vacuum pumps, often called water ring pumps, are a cornerstone in many industrial and laboratory settings. Unlike dry vacuum pumps, these systems use water as both a sealant and coolant, offering unique advantages for specific applications. But how do they work, and are they the right choice for your needs?

How Water Creates the Vacuum: The Core Operating Principle

At the heart of a water ring pump is a simple yet effective mechanism:

- The pump is partially filled with water.

- An off-center impeller rotates, flinging water outward via centrifugal force to form a liquid ring.

- Crescent-shaped cavities between the impeller and water ring expand to draw in gas (creating vacuum) and contract to compress and discharge it.

This design eliminates the need for mechanical seals or lubricants in the compression chamber, reducing contamination risks—a critical feature for labs handling sensitive materials.

Key Advantages: Why Choose a Water Ring Pump?

Water circulating pumps excel in scenarios where purity, safety, and handling of volatile substances are priorities:

- Chemical Compatibility: Ideal for pumping corrosive or solvent-laden gases, as water dilutes and neutralizes many reactive compounds.

- Heat Sensitivity: The water absorbs heat generated during compression, protecting temperature-sensitive samples.

- Low Maintenance: No oil changes or vane replacements (common in dry pumps), though regular water replenishment is needed.

- Explosion Safety: Water’s inert nature minimizes ignition risks when processing flammable vapors.

Did you know? Research shows water ring pumps can handle microscopic solids and vapors without damage, making them versatile for filtration and distillation processes.

Common Applications: Where Water Ring Pumps Shine

From labs to industrial plants, these pumps address real-world challenges:

- Laboratory Evacuation: Creating rough vacuums (1–760 Torr) for freeze dryers, filtration systems, and glassware drying.

- Chemical Processing: Safely managing volatile solvents in pharmaceutical synthesis or material testing.

- Environmental Control: Extracting moisture or hazardous gases during sample preparation.

- Food & Beverage: Gentle vacuum packaging without contaminating products with oil residues.

A sugar mill case study revealed how water ring pumps improved ash management by tolerating particulate-laden gases that would clog dry pumps.

Important Considerations and Limitations

While versatile, water ring pumps aren’t universal solutions:

- Energy Efficiency: Continuous water circulation increases power usage compared to dry pumps.

- Temperature Limits: Water freezing or evaporating at extremes can disrupt operation.

- Vacuum Range: Best for rough vacuums; high-vacuum applications require supplementary pumps.

Pro Tip: Always monitor the water ring’s vapor pressure—evaporation loss breaks the vacuum seal.

Selecting and Maintaining Your Water Circulating Pump

Choosing the Right Pump

Match your needs to these factors:

- Flow Rate: Labs typically require 10–500 m³/h.

- Chemical Resistance: Opt for stainless steel or coated models for corrosive environments.

- Water Quality: Use distilled water to prevent mineral buildup.

Maintenance Essentials

- Daily: Check water levels and clarity; replace if contaminated.

- Monthly: Inspect impellers for erosion from abrasive particles.

- Annually: Flush the system to remove scale deposits.

Upgrade Your Lab’s Efficiency with KINTEK’s Reliable Solutions

Whether you’re evacuating sensitive systems or handling aggressive chemicals, KINTEK’s water circulating vacuum pumps deliver precision and safety. Explore our range designed for laboratory durability—contact us today to find your ideal vacuum solution!

Word Count: 3,250

Products You Might Be Looking For:

Explore large-capacity chilling circulators

Discover high-volume cooling systems

Related Products

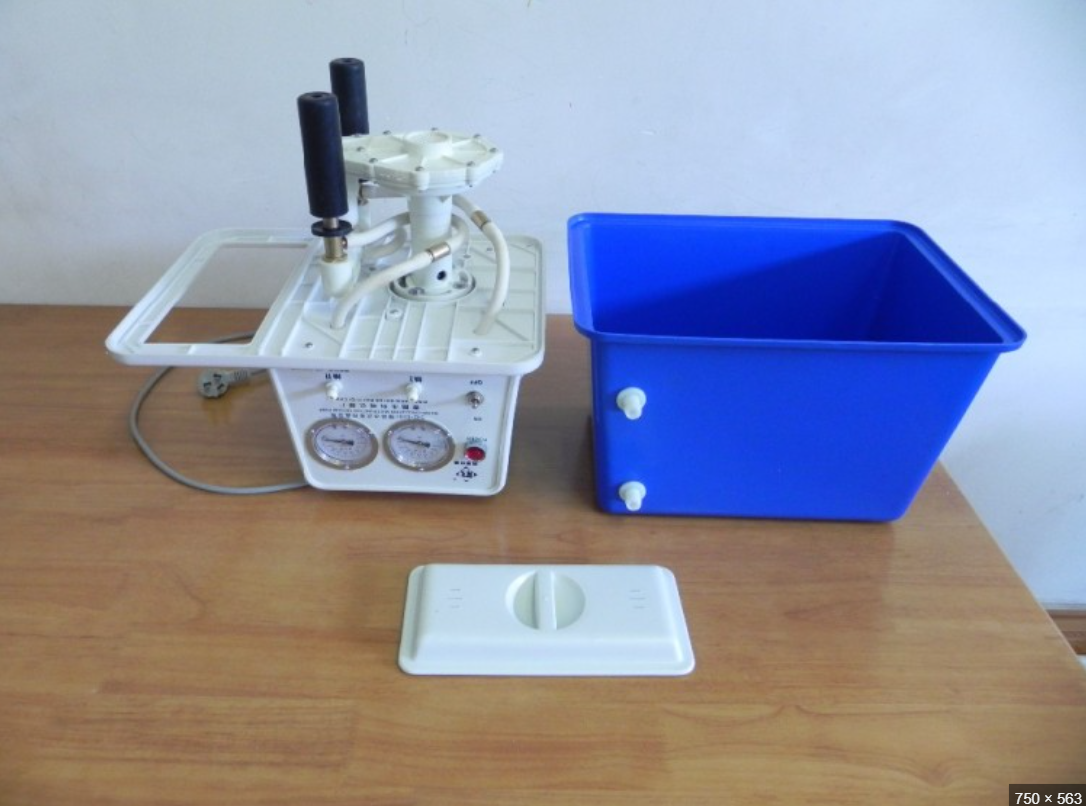

- Laboratory Benchtop Water Circulating Vacuum Pump for Lab Use

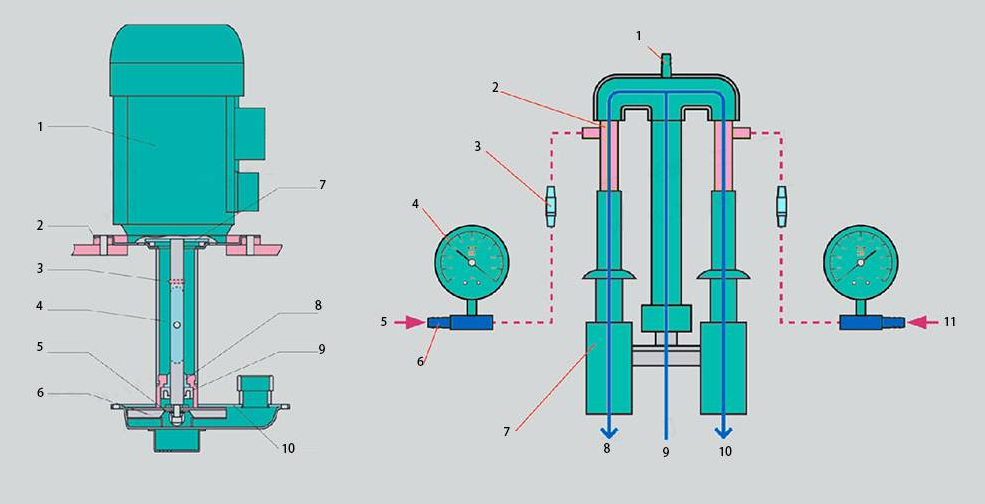

- Laboratory Vertical Water Circulating Vacuum Pump for Lab Use

- 304 316 Stainless Steel Vacuum Ball Valve Stop Valve for High Vacuum Systems

- Benchtop Laboratory Vacuum Freeze Dryer

- KF/ISO/CF Ultra-High Vacuum Stainless Steel Flange Pipe/Straight Pipe/Tee/Cross

Related Articles

- Discover The Benefits of Using A Rotary Evaporator

- How to Choose and Optimize Water Circulating Vacuum Pumps for Your Lab

- From Chemistry to Cooking The Versatility of Rotary Vacuum Evaporator

- Exploring the Science Behind Rotary Evaporators: How They Work and Their Applications

- Choosing the Right Rotary Vacuum Evaporator for Your Lab