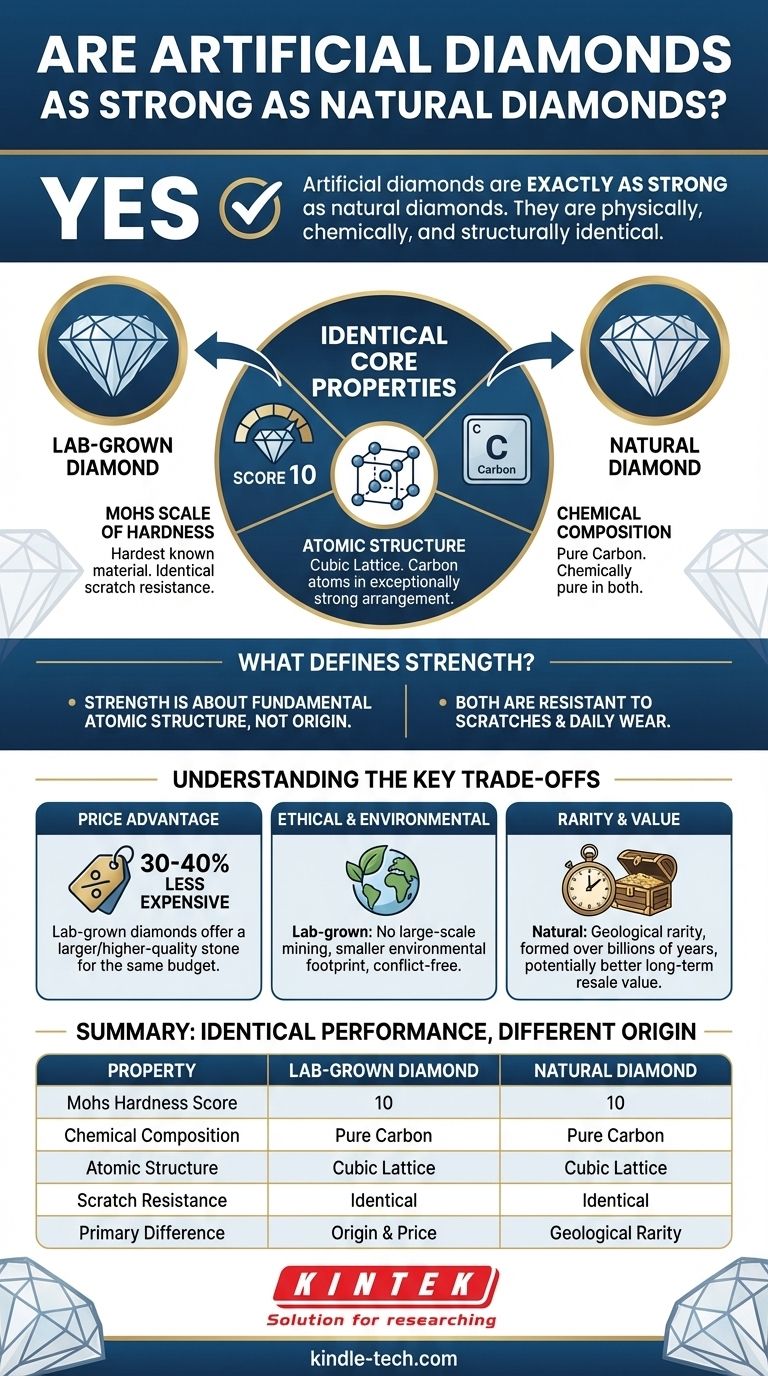

Yes, artificial diamonds are exactly as strong as natural diamonds. A lab-grown diamond is physically, chemically, and structurally identical to a mined diamond. Both are pure carbon crystallized in a cubic lattice, and both register a perfect 10 on the Mohs scale of hardness, making them the hardest known natural material.

The core takeaway is that lab-grown diamonds are not imitations or substitutes; they are real diamonds. Their different origin has no impact on their physical properties, including their exceptional hardness and durability.

What Defines a Diamond's Strength?

The strength and durability of a diamond are not a matter of its origin, but of its fundamental atomic structure. This is where lab-grown and natural diamonds are indistinguishable.

The Mohs Scale of Hardness

Hardness is a material's resistance to being scratched. The Mohs scale ranks minerals from 1 (softest) to 10 (hardest).

Both natural and lab-created diamonds score a 10 on this scale. This means a lab diamond is just as resistant to scratches and daily wear as its mined counterpart.

Identical Atomic and Chemical Structure

A diamond's incredible strength comes from its crystal lattice, where carbon atoms are bonded together in an exceptionally strong and rigid structure.

Lab processes, whether CVD or HPHT, are designed to replicate this exact atomic arrangement. The result is a stone that is chemically pure carbon and physically identical to a diamond formed in the earth's mantle.

Are There Any Physical Differences at All?

While their core properties are identical, minuscule markers related to their formation can be detected, but only with highly specialized gemological equipment.

Indistinguishable to the Naked Eye

To the unaided eye, even a trained jeweler's eye, a lab-grown diamond is impossible to distinguish from a natural one. They exhibit the same fire, brilliance, and sparkle.

The Need for Specialized Equipment

The only way to differentiate between them is by using advanced machines that can detect subtle differences in their crystal growth patterns and the types of trace impurities present. These differences have no impact on the diamond's beauty or durability.

Understanding the Key Trade-offs

Choosing between a lab-grown and a natural diamond isn't about quality or strength, but about other priorities like cost, origin, and the perception of rarity.

The Clear Advantage of Price

The most significant difference is cost. Lab-grown diamonds are typically 30-40% less expensive than natural diamonds of comparable size and quality. This allows you to acquire a larger or higher-quality stone for the same budget.

Ethical and Environmental Considerations

Lab-grown diamonds are created without the need for large-scale mining operations. This gives them a significantly smaller environmental footprint and ensures they are free from the ethical concerns associated with "conflict diamonds."

The Perception of Rarity and Value

The primary value proposition for natural diamonds is their geological rarity, formed over billions of years. Lab-grown diamonds can be produced on demand, which affects their long-term resale value and the traditional perception of them as a rare gemstone.

How to Apply This to Your Decision

Your choice depends entirely on what you value most in a diamond.

- If your primary focus is on physical performance, brilliance, and budget: A lab-grown diamond is an exceptional choice, offering identical strength and beauty for a lower cost.

- If your primary focus is on traditional rarity and potential long-term value retention: A natural diamond remains the conventional choice due to its finite supply and geological origin story.

Ultimately, you can be confident that choosing a lab-grown diamond involves no compromise on its strength or durability.

Summary Table:

| Property | Lab-Grown Diamond | Natural Diamond |

|---|---|---|

| Mohs Hardness Score | 10 | 10 |

| Chemical Composition | Pure Carbon | Pure Carbon |

| Atomic Structure | Cubic Lattice | Cubic Lattice |

| Scratch Resistance | Identical | Identical |

| Primary Difference | Origin & Price | Geological Rarity |

Ready to explore high-quality materials for your research or testing needs? At KINTEK, we specialize in providing premium lab equipment and consumables. Whether you're working with advanced materials like diamonds or other substrates, our expertise ensures you have the reliable tools for precise analysis and consistent results. Contact our team today to discuss how we can support your laboratory's specific requirements and enhance your workflow efficiency.

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What role does Chemical Vapor Deposition (CVD) equipment play in the preparation of C/C composites? Expert Analysis

- What are the main advantages of Chemical Vapor Deposition (CVD)? Achieve Precision Coating for Complex Geometries

- What function does CVD equipment serve in rhodium-modified coatings? Achieve Deep Diffusion and Microstructural Precision

- Why are carbon nanotubes important in industry? Unlocking Next-Generation Material Performance

- What is a CVD tube furnace? A Complete Guide to Thin-Film Deposition