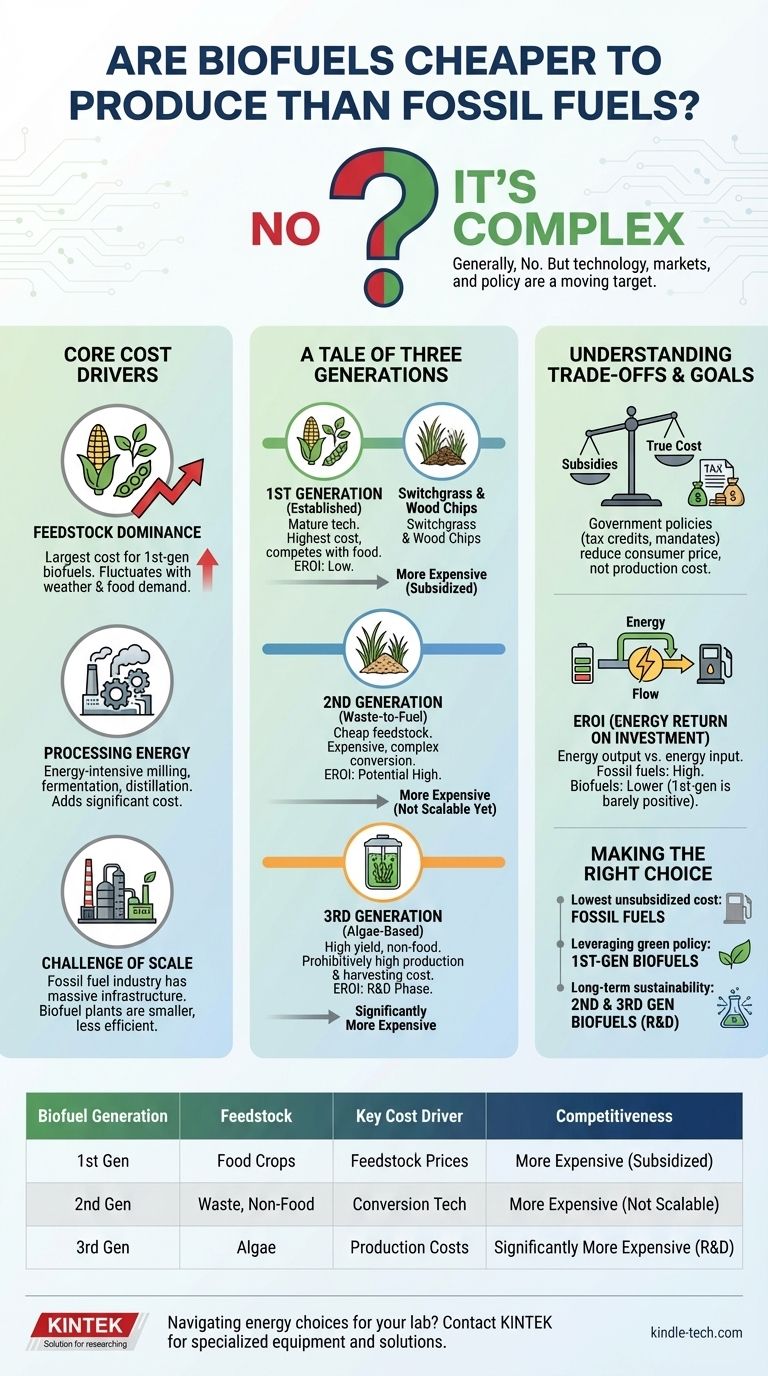

As a general rule, no. The production cost of most commercially available biofuels, such as corn ethanol and soy biodiesel, is currently higher than the production cost of their fossil fuel counterparts, gasoline and diesel. This simple answer, however, obscures a more complex reality shaped by technology, agricultural markets, and government policy. The cost parity between these energy sources is not a fixed state but a moving target.

The economic viability of biofuels hinges on three critical factors: the type of feedstock used (e.g., corn vs. agricultural waste), the maturity of the conversion technology, and the scale of production. Without government subsidies, the highly optimized and massive scale of the fossil fuel industry gives it a decisive production cost advantage over nearly all biofuels today.

The Core Factors Driving Biofuel Costs

To understand why biofuels are typically more expensive, we must break down the costs into their fundamental components. Unlike fossil fuels, which are extracted, biofuel production is more akin to a specialized form of farming combined with industrial processing.

The Dominance of Feedstock Prices

The single largest cost component for first-generation biofuels is the raw material, or feedstock. For ethanol, this is typically corn; for biodiesel, it is often soybeans or palm oil.

These are agricultural commodities with prices that fluctuate based on weather, global demand for food and animal feed, and farming costs like fertilizer and fuel. This "food vs. fuel" competition creates inherent price volatility and a floor on how cheap the feedstock can ever be.

The Energy Demands of Processing

Converting solid biomass into liquid fuel is an energy-intensive process. It involves steps like milling the grain, fermentation by yeast, and distillation to separate the ethanol from water.

These industrial processes require significant thermal and electrical energy, which adds a substantial operational cost to every gallon produced. While refining crude oil is also energy-intensive, the sheer scale of refineries provides efficiencies that smaller biofuel plants struggle to match.

The Challenge of Scale

The global fossil fuel industry operates at an immense, deeply entrenched scale built over a century. Its vast infrastructure—from supertankers to pipelines and refineries—creates massive economies of scale that drive down the per-gallon cost of production.

The biofuel industry, while growing, is a fraction of this size. Individual plants are smaller, and the logistics of collecting, transporting, and storing bulky biomass feedstocks are less efficient than pumping crude oil through a pipeline.

A Tale of Three Generations: Why Not All Biofuels Are Equal

The term "biofuel" is a broad category. The cost, sustainability, and viability differ dramatically depending on the generation of the technology.

First Generation: The Established but Flawed Standard

These are the biofuels in wide use today, primarily corn ethanol and soy biodiesel. They are based on mature, well-understood technology, making them the most commercially viable biofuel option.

However, they are also the most expensive to produce relative to fossil fuels and suffer from the direct competition with the food supply, making their long-term cost-effectiveness and sustainability questionable.

Second Generation: The Promise of Waste-to-Fuel

Also known as cellulosic biofuels, these are produced from non-food sources like switchgrass, wood chips, and agricultural waste (corn stalks, wheat straw).

The feedstock itself is very cheap or even free. The primary challenge and cost driver is the complex and expensive technology required to break down tough cellulose into fermentable sugars. While promising, these technologies are not yet cost-competitive at a commercial scale.

Third Generation: The Algae-Based Future

This generation focuses on feedstocks like algae, which can be grown in ponds or bioreactors on non-arable land, avoiding competition with food crops. Algae are incredibly productive and can yield far more fuel per acre than any land crop.

The barrier here is almost entirely technological. The cost of building, maintaining, and harvesting algae at scale, then extracting the oils, is currently prohibitively expensive for fuel production. It remains a subject of intense research and development.

Understanding the Trade-offs and Hidden Costs

A simple comparison of production cost at the factory gate misses crucial parts of the economic picture.

Subsidies vs. True Production Cost

The price you see at the pump for an ethanol blend (like E10 or E85) is not a reflection of its true production cost. Governments, particularly in the U.S., provide significant tax credits, blending mandates, and other subsidies to make biofuels market-competitive.

These policies reduce the consumer price but do not lower the underlying production cost. They are policy tools designed to nurture a domestic energy industry and reduce reliance on foreign oil, but they mask the true economics.

Energy Return on Investment (EROI)

A more fundamental metric is Energy Return on Investment (EROI). This measures how many units of energy you get out for every one unit of energy you put into producing the fuel.

Crude oil has historically had a very high EROI. First-generation biofuels have a much lower EROI, sometimes barely above 1, meaning you get only slightly more energy out than you put in. Second-generation biofuels have the potential for a much higher EROI, but the technology is not yet mature.

Making the Right Choice for Your Goal

The "cheaper" fuel depends entirely on your objective, timeline, and whether you are considering market price or true production cost.

- If your primary focus is the lowest unsubsidized production cost today: Fossil fuels remain the clear winner due to unparalleled scale and technological maturity.

- If your primary focus is leveraging current green energy policies and mandates: First-generation biofuels are the only commercially available and scalable option, though their financial viability is directly tied to ongoing government support.

- If your primary focus is long-term energy independence and sustainability: Second and third-generation biofuels hold the most promise, but they require significant investment in research and development before they can become economically competitive.

Ultimately, understanding the true cost of our fuel requires looking beyond the pump price to the complex interplay of agriculture, technology, and policy.

Summary Table:

| Biofuel Generation | Feedstock | Key Cost Driver | Current Cost Competitiveness vs. Fossil Fuels |

|---|---|---|---|

| First Generation | Food Crops (Corn, Soy) | High Feedstock Prices | More Expensive (Relies on subsidies) |

| Second Generation | Agricultural Waste, Non-Food Plants | Complex & Expensive Conversion Tech | More Expensive (Not yet commercially scalable) |

| Third Generation | Algae | Prohibitively High Production & Harvesting Costs | Significantly More Expensive (R&D Phase) |

Navigating the complex world of energy sources for your laboratory? The choice of fuel and energy systems can impact your operational costs, sustainability goals, and research outcomes. KINTEK specializes in providing high-quality lab equipment and consumables tailored to your specific needs, whether your focus is on traditional methods or pioneering green alternatives. Let our experts help you optimize your lab's efficiency and align with your energy objectives. Contact us today to discuss how we can support your laboratory's journey.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- 5L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

- Laboratory Hybrid Tissue Grinding Mill

People Also Ask

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success