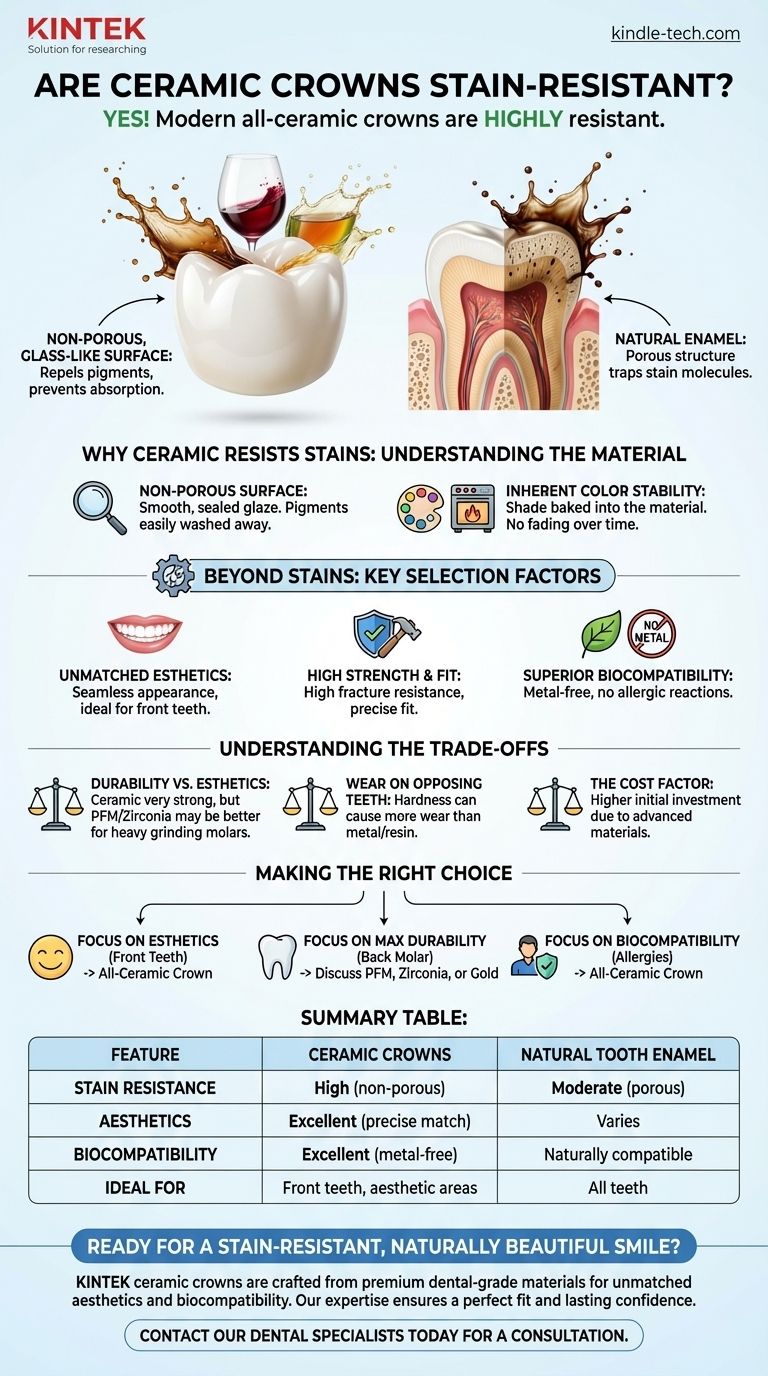

In short, yes. Modern all-ceramic crowns are highly resistant to staining. Their non-porous, glass-like surface does not absorb pigments from foods and drinks like coffee, tea, or red wine in the way that natural tooth enamel can.

While ceramic crowns offer superior stain resistance and aesthetics, the best choice of crown material requires balancing these benefits against factors like the tooth's location in the mouth, your bite force, and overall long-term durability.

Understanding the Material: Why Ceramic Resists Stains

To understand why ceramic crowns are a leading choice for aesthetics, it's important to look at the material's fundamental properties. Their resistance to discoloration is not an accident but a core characteristic of their composition.

The Non-Porous Surface

The key to stain resistance is the non-porous nature of dental-grade ceramic. Unlike natural tooth enamel, which has microscopic pores that can trap stain-causing molecules, a finished ceramic crown has a smooth, sealed surface.

This glaze effectively prevents pigments from penetrating the material, allowing them to be easily washed or brushed away.

Inherent Color Stability

The color of a ceramic crown is not a surface-level coating. It is baked into the material itself during its fabrication.

This means the shade is stable and will not fade or change over time due to external factors, ensuring its aesthetic quality lasts for many years.

Beyond Stains: Key Factors in Crown Selection

While stain resistance is a significant advantage, it is only one piece of the puzzle. A proper evaluation involves looking at the complete performance profile of the material.

Unmatched Esthetics

As the references note, all-ceramic crowns provide excellent esthetics. They can be precisely matched to the color, translucency, and shape of your natural teeth.

This makes them the premier choice for highly visible teeth, particularly the front teeth, where a seamless appearance is paramount.

High Strength and Fit

Modern ceramics possess high fracture resistance and are fabricated with incredible precision. A high-strength ceramic core, or coping, allows the crown to withstand the significant forces of chewing.

This combination of strength and accurate fit is critical for the clinical success and longevity of any dental restoration.

Superior Biocompatibility

For individuals with metal allergies or sensitivities, all-ceramic crowns are the ideal solution. Because they contain no metal, the risk of an allergic reaction or gum irritation is virtually eliminated.

Understanding the Trade-offs

No single dental material is perfect for every situation. Being aware of the trade-offs is essential for making an informed decision with your dental provider.

Durability vs. Esthetics

While very strong, all-ceramic crowns may not be as durable as Porcelain-Fused-to-Metal (PFM) or full-metal crowns under extreme force. For back molars that endure immense grinding and chewing pressure, a PFM or zirconia crown might be recommended for its superior strength.

Potential Wear on Opposing Teeth

The hardness of ceramic, which contributes to its durability, can be a double-edged sword. In some cases, a ceramic crown can cause slightly more wear on the opposing natural tooth it bites against compared to a metal or resin crown.

The Cost Factor

Generally, all-ceramic crowns represent a higher initial investment compared to PFM or metal crowns. This cost reflects the advanced materials and laboratory processes required to achieve their superior aesthetic results.

Making the Right Choice for Your Goal

Your choice of crown material should be a collaborative decision with your dentist, based on your specific clinical needs and personal priorities.

- If your primary focus is aesthetics, especially for front teeth: An all-ceramic crown is the undisputed top choice for its natural appearance and stain resistance.

- If your primary focus is maximum durability for a back molar: You and your dentist should discuss the benefits of a PFM, full zirconia, or gold crown.

- If your primary focus is biocompatibility due to metal allergies: An all-ceramic crown is the safest and most effective solution.

Ultimately, a well-informed conversation with your dentist will ensure you select the crown that best serves your long-term health and confidence.

Summary Table:

| Feature | Ceramic Crowns | Natural Tooth Enamel |

|---|---|---|

| Stain Resistance | High (non-porous surface) | Moderate (porous, can stain) |

| Aesthetics | Excellent (precise color matching) | Varies |

| Biocompatibility | Excellent (metal-free) | Naturally compatible |

| Ideal For | Front teeth, high aesthetic areas | All teeth |

Ready to achieve a stain-resistant, naturally beautiful smile?

Ceramic crowns from KINTEK are crafted from premium dental-grade materials, ensuring a non-porous, glass-like surface that resists stains from coffee, tea, and wine while providing unmatched aesthetics and biocompatibility.

Our expertise in dental restorations means you get a crown that fits perfectly, looks natural, and lasts for years.

Contact our dental specialists today for a consultation and see how a ceramic crown can restore your confidence and protect your smile!

Visual Guide

Related Products

- Custom-Made Alumina Zirconia Special-Shaped Ceramic Plates for Engineering Advanced Fine Ceramics Processing

- Precision Machined Yttria Stabilized Zirconia Ceramic Plate for Engineering Advanced Fine Ceramics

- Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

- Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

- Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

People Also Ask

- How can different materials have different heat capacity? Unlocking the Microscopic Secrets of Energy Storage

- What is the main difference between soldering and brazing? Choose the Right Metal Joining Method

- What are the three types of coating? A Guide to Architectural, Industrial, and Special Purpose

- What are the strengths of brazing? Achieve Strong, Clean, and Precise Metal Joining

- How many types of hardening techniques are there? A Multi-Layered Security Strategy Explained