Yes, as a class of materials, ceramics are renowned for their exceptional chemical resistance. This stability is a core characteristic that makes them suitable for everything from ancient cooking vessels to advanced industrial components. Their inherent inertness stems directly from their fundamental atomic structure.

The powerful chemical bonds holding ceramic materials together make them highly resistant to corrosion and chemical attack. However, this resistance is not absolute; its effectiveness depends on the specific type of ceramic and the severity of the chemical environment, particularly against certain powerful acids and high-temperature alkalis.

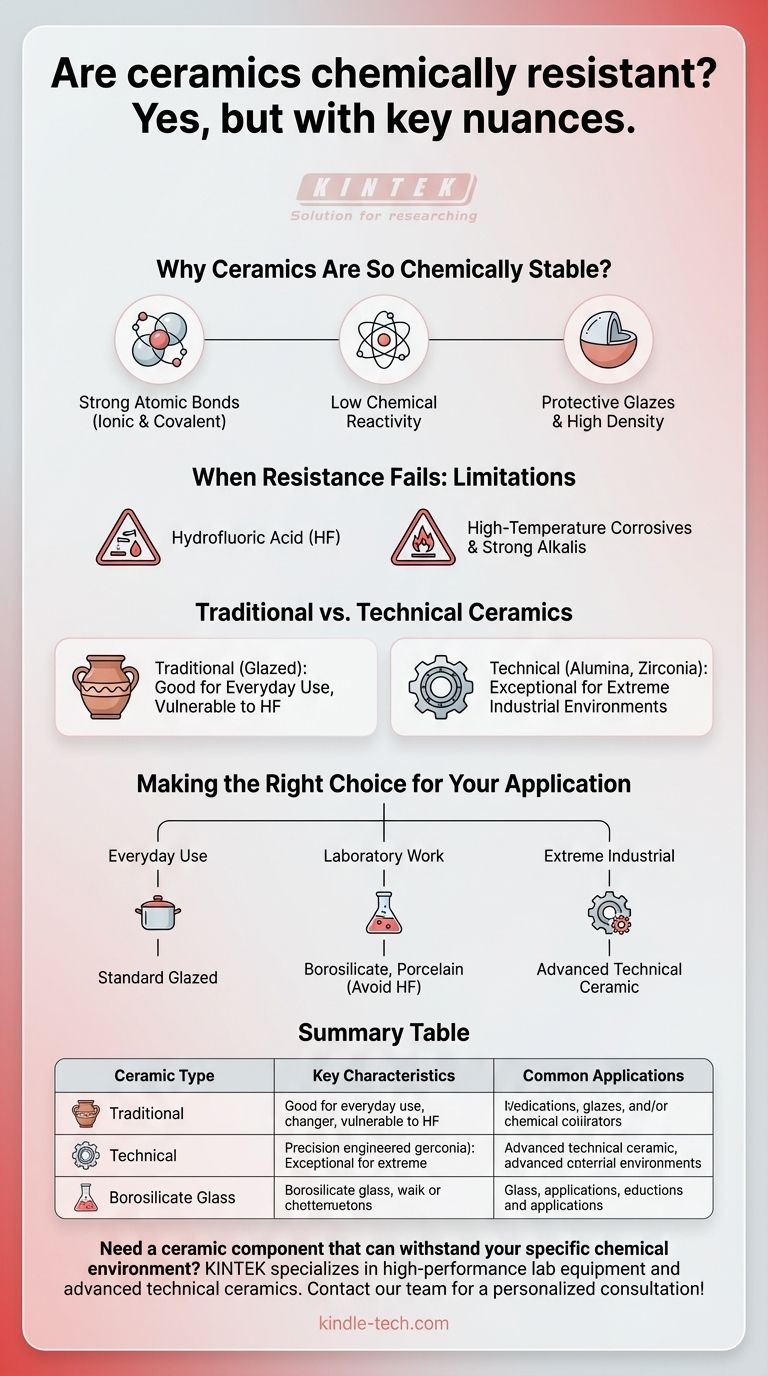

Why Are Ceramics So Chemically Stable?

The chemical durability of ceramics is not an accident; it is a direct result of their atomic composition and structure. Understanding this foundation is key to knowing when and where to rely on them.

The Power of Strong Atomic Bonds

Ceramics are typically characterized by very strong ionic and covalent bonds. These bonds hold the atoms together tightly, requiring a significant amount of energy to be broken.

This stable atomic arrangement leaves very few "free" electrons available to participate in chemical reactions, rendering the material largely inert.

Low Chemical Reactivity

Unlike metals, which readily corrode by losing electrons (oxidation), most ceramics are already in a highly stable, oxidized state. This makes them resistant to further oxidation and a wide range of other chemical reactions.

The Critical Role of Glazes and Density

For many traditional ceramics, a glassy glaze is applied to the surface. This creates a non-porous, chemically inert barrier that seals the underlying ceramic body, preventing liquids and chemicals from penetrating.

Advanced technical ceramics are often manufactured to achieve near-total density, eliminating porosity and maximizing their inherent chemical resistance without the need for a glaze.

Understanding the Trade-offs: When Resistance Fails

No material is completely indestructible. While extraordinarily resilient, ceramics have specific vulnerabilities that are critical to understand for demanding applications.

The Exception: Hydrofluoric Acid

The most well-known limitation involves hydrofluoric acid (HF). This highly corrosive acid is one of the few chemicals that can aggressively attack silica-based ceramics, which includes glass, porcelain, and stoneware.

High-Temperature Corrosives

At very high temperatures, certain molten metals, salts, and strong alkaline (basic) solutions can begin to corrode even advanced ceramics. The extreme thermal energy can overcome the material's bond strength.

The Difference Between Traditional and Technical Ceramics

There is a vast performance gap between different types of ceramics. A traditional earthenware pot is far less resistant than a high-purity technical ceramic like alumina or zirconia.

Technical ceramics are engineered with specific compositions and microstructures to withstand the most aggressive industrial environments, far beyond the capabilities of consumer-grade materials.

Making the Right Choice for Your Application

Matching the ceramic to the chemical environment is the most important step for ensuring reliability and safety.

- If your primary focus is everyday use (cookware, dishes): Standard glazed ceramics are more than sufficient, as they are inert and stable against virtually all foodstuffs and cleaning agents.

- If your primary focus is general laboratory work: Borosilicate glass and porcelain are industry standards for their broad chemical resistance, but you must avoid hydrofluoric acid at all costs.

- If your primary focus is extreme industrial environments: You must select an advanced technical ceramic specifically engineered to withstand the unique combination of chemicals and high temperatures in your process.

By understanding these core principles, you can confidently leverage the remarkable chemical stability of ceramics for your specific goal.

Summary Table:

| Ceramic Type | Key Characteristics | Common Applications |

|---|---|---|

| Traditional (Glazed) | Good resistance to common chemicals; vulnerable to HF acid. | Cookware, tableware, decorative items. |

| Technical (Alumina, Zirconia) | Exceptional resistance to acids, alkalis, and high temperatures. | Lab equipment, industrial components, medical devices. |

| Borosilicate Glass | High thermal shock resistance; broadly chemically inert (except HF). | Laboratory glassware, reactors. |

Need a ceramic component that can withstand your specific chemical environment?

At KINTEK, we specialize in high-performance lab equipment and consumables, including advanced technical ceramics engineered for extreme durability. Our experts can help you select the perfect material to ensure the longevity and reliability of your laboratory processes.

Contact our team today for a personalized consultation!

Visual Guide

Related Products

- Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

- Advanced Engineering Fine Ceramics Boron Nitride (BN) Ceramic Parts

- Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

People Also Ask

- What is the temperature resistance of silicon carbide? Withstands Extreme Heat Up to 1500°C

- What are the properties of SiC? Unlock High-Temperature, High-Frequency Performance

- What are the characteristics of SiC? Unlock High-Temp, Hard, and Chemically Inert Performance

- What is the strongest ceramics? Silicon Carbide Leads in Hardness & Thermal Strength

- Which is harder silicon carbide or tungsten carbide? Discover the Key to Material Selection