For anyone who dreads cleaning their oven, pyrolytic models are unequivocally better. They use extremely high temperatures to incinerate grease and food residue into a fine ash that you simply wipe away. This technology offers the most effective, hands-off cleaning solution available, but whether it's the "better" choice for you depends on balancing its convenience against its higher initial cost.

The core decision is not just about cleaning. It's about weighing the ultimate convenience and potential for better cooking performance of a pyrolytic oven against its premium price tag.

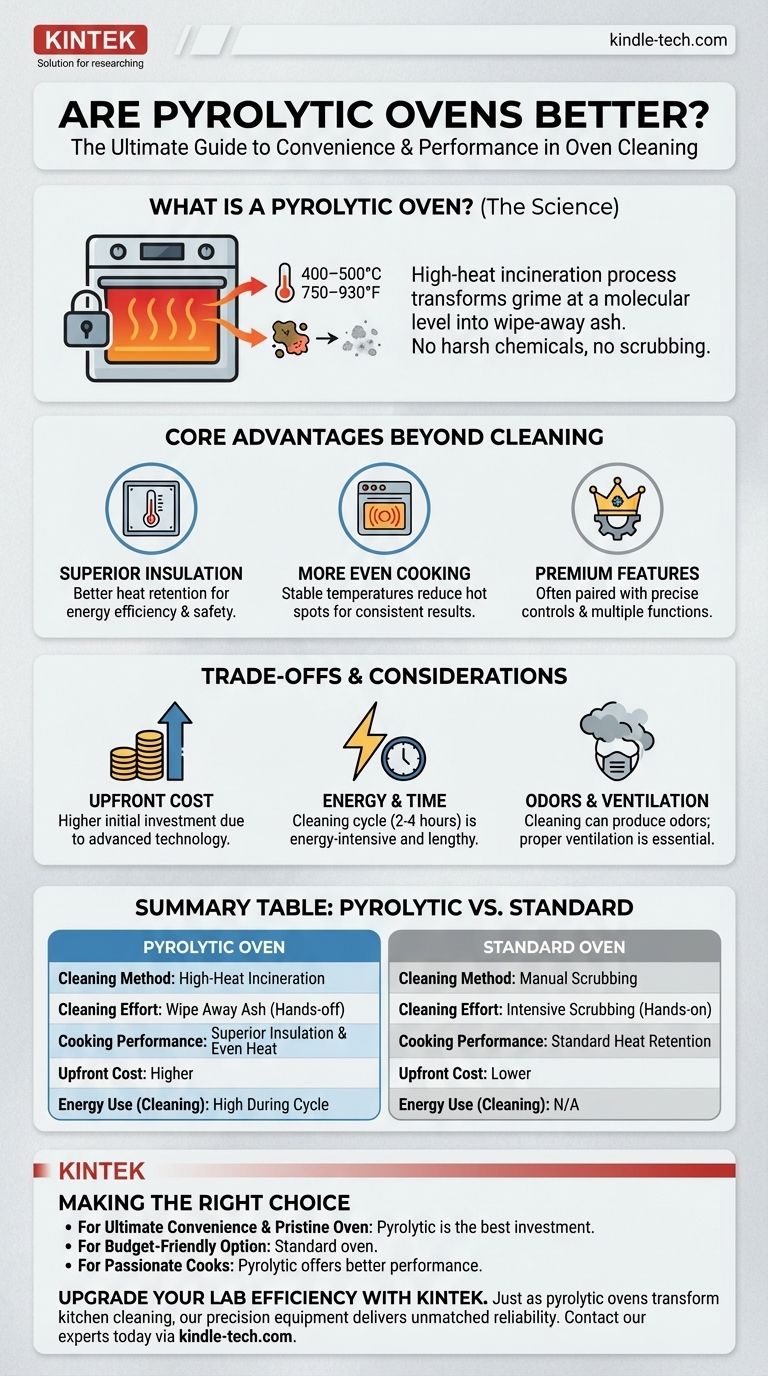

What is a Pyrolytic Oven? The Science of Self-Cleaning

The primary benefit of a pyrolytic oven is its self-cleaning function, which is fundamentally different from other cleaning methods. It is an active, high-heat process that transforms grime at a molecular level.

How Pyrolysis Works

During a pyrolytic cleaning cycle, the oven's door automatically locks for safety. The internal temperature then skyrockets to around 400-500°C (750-930°F). At this extreme heat, a process called pyrolysis occurs, where complex organic matter (like baked-on grease, sugar, and food spills) is broken down and carbonized without the presence of oxygen.

The End Result: Ash, Not Grime

This incineration process reduces all residue to a small pile of fine, sterile ash. Once the oven has completed its cycle and cooled down completely, you can easily wipe this ash away with a damp cloth. No harsh chemicals, no intense scrubbing, and no residual fumes are required.

The Core Advantages Beyond Cleaning

While the self-cleaning feature is the main selling point, the design required for pyrolysis often leads to a superior cooking appliance overall.

Superior Insulation and Heat Retention

To safely handle the extreme temperatures of a cleaning cycle, pyrolytic ovens are built with significantly more robust insulation than standard models. This heavy-duty insulation provides a major benefit during normal cooking by retaining heat far more effectively.

More Even Cooking Results

Better heat retention means a more stable and consistent internal temperature. This stability translates directly to more even cooking, reducing hot spots and ensuring better results for everything from baking delicate cakes to roasting large cuts of meat. The oven doesn't have to work as hard to maintain its temperature, improving energy efficiency during regular use.

Often Paired with Premium Features

Pyrolytic functionality is typically found on mid- to high-end ovens. Because of this, they are often packaged with other advanced features like precise digital controls, multiple cooking functions (like steam or air fry), and higher-quality construction materials.

Understanding the Trade-offs and Considerations

A pyrolytic oven is an excellent tool, but it is not without its trade-offs. An objective assessment requires looking at the downsides.

The Upfront Cost

The most significant barrier is price. The advanced technology, robust construction, and superior insulation make pyrolytic ovens more expensive than their non-pyrolytic counterparts.

Energy Consumption of the Cleaning Cycle

A full pyrolytic cycle is energy-intensive, typically lasting between two and four hours. While you will likely only run this cycle a few times per year, it does represent a notable, periodic energy cost. This is partly offset by better efficiency during everyday cooking, but it's a factor to consider.

Cycle Time and Odors

The cleaning cycle is a lengthy process during which the oven is unusable. As food residue is burned off, it can produce strong odors and some smoke. Ensuring your kitchen is well-ventilated during the cycle is essential.

Comparison to Other Cleaning Methods

Catalytic liners are panels that absorb grease but are less effective on sugar spills and degrade over time. Steam cleaning helps loosen light grime but lacks the power to tackle heavy, baked-on messes and still requires manual wiping. Pyrolysis is the only method that effectively eliminates all types of food soil with almost no physical effort.

Making the Right Choice for Your Kitchen

The decision to invest in a pyrolytic oven should be based on your personal priorities for convenience, budget, and cooking performance.

- If your primary focus is ultimate convenience and a pristine oven: A pyrolytic model is the best choice and is worth the investment to eliminate the chore of oven cleaning.

- If your primary focus is minimizing upfront cost: A traditional oven that requires manual cleaning is the most budget-friendly option.

- If you are a passionate cook seeking performance: The superior insulation and heat stability of a pyrolytic oven can provide a noticeable improvement in your cooking, making it a worthy upgrade beyond just the cleaning function.

Ultimately, choosing a pyrolytic oven is an investment in freeing yourself from one of the most disliked tasks in the kitchen while often gaining a higher-performing appliance.

Summary Table:

| Feature | Pyrolytic Oven | Standard Oven |

|---|---|---|

| Cleaning Method | High-heat incineration (pyrolysis) | Manual scrubbing with chemicals |

| Cleaning Effort | Wipe away ash; no scrubbing | Hands-on, intensive scrubbing |

| Cooking Performance | Superior insulation & even heat | Standard heat retention |

| Upfront Cost | Higher | Lower |

| Energy Use (Cleaning) | High during cycle | N/A |

Upgrade your lab efficiency with KINTEK's precision equipment. Just as a pyrolytic oven transforms kitchen cleaning, our lab ovens and furnaces deliver unmatched reliability and performance for your laboratory needs. Whether you require precise temperature control for materials testing or durable consumables for daily workflows, KINTEK specializes in equipment that saves you time and improves results. Contact our experts today via our Contact Form to find the perfect solution for your lab!

Visual Guide

Related Products

- 1200℃ Muffle Furnace Oven for Laboratory

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Large Vertical Graphite Vacuum Graphitization Furnace

- Graphite Vacuum Furnace Bottom Discharge Graphitization Furnace for Carbon Materials

- Vacuum Heat Treat and Pressure Sintering Furnace for High Temperature Applications

People Also Ask

- How does thermal uniformity of a muffle furnace affect SA508 alloy? Master Carbide Precipitation and Fatigue Resistance

- What is the difference between muffle furnace and hot air oven? Choose the Right Heating Tool for Your Lab

- How do you ash a sample? Choose the Right Method for Accurate Inorganic Analysis

- How do high-temperature furnaces ensure the accuracy of Inconel oxidation testing? Achieve Stable Thermal Environments

- What are the hazards of a muffle furnace? Understanding the Critical Risks for Lab Safety

- How does a high-temperature air oxidation furnace achieve rapid thickening of the oxide layer on Zircaloy-4?

- What is the alternative to the muffle furnace? Find the Right High-Temp Solution for Your Lab

- What is the process of a muffle furnace? From Electricity to Precision High-Temp Control