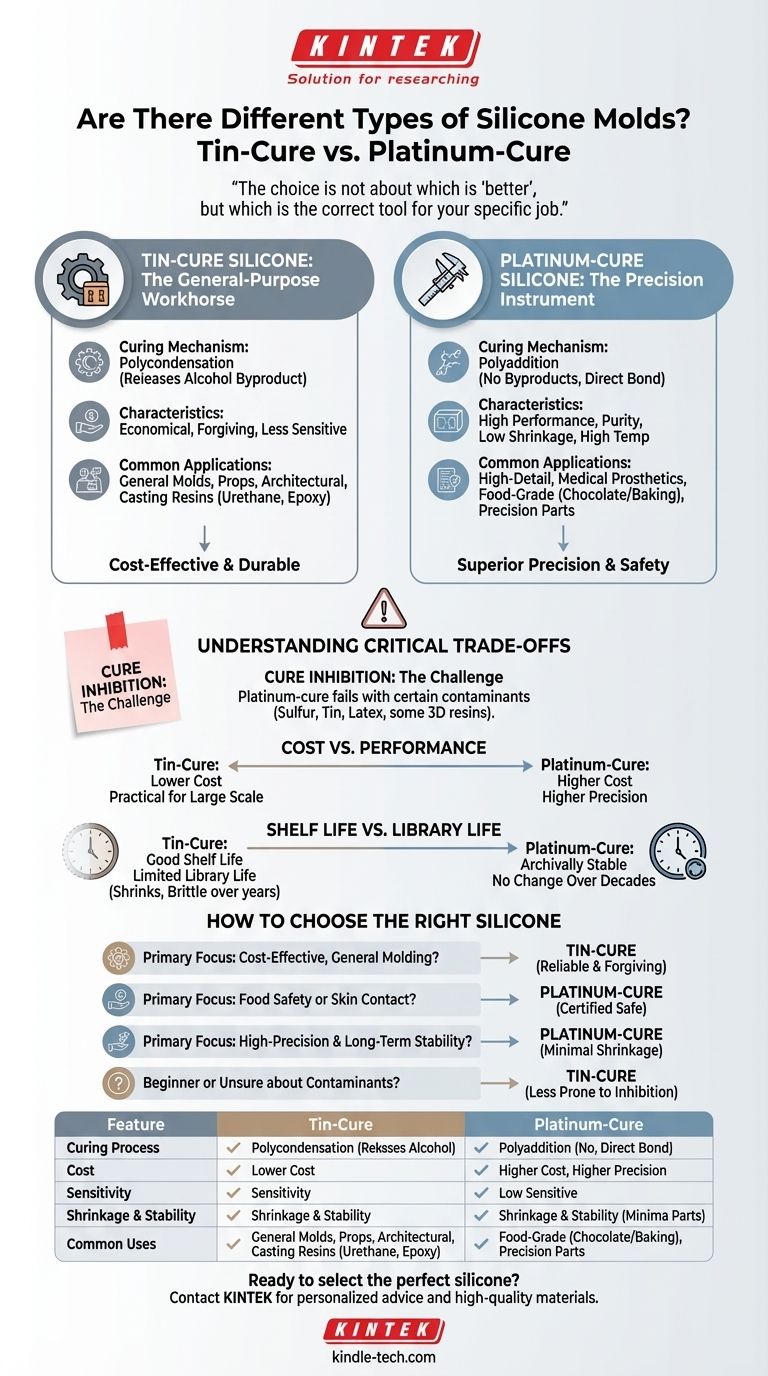

Yes, there are two primary types of silicone used for mold making. These are known as tin-cure (or polycondensation) silicones and platinum-cure (or polyaddition) silicones. The fundamental difference lies in their chemical curing process, which dictates their performance, cost, and suitable applications.

The choice between tin-cure and platinum-cure silicone is not about which is "better" overall, but which is the correct tool for your specific job. Tin-cure is a reliable, cost-effective workhorse, while platinum-cure offers superior precision and safety for sensitive applications.

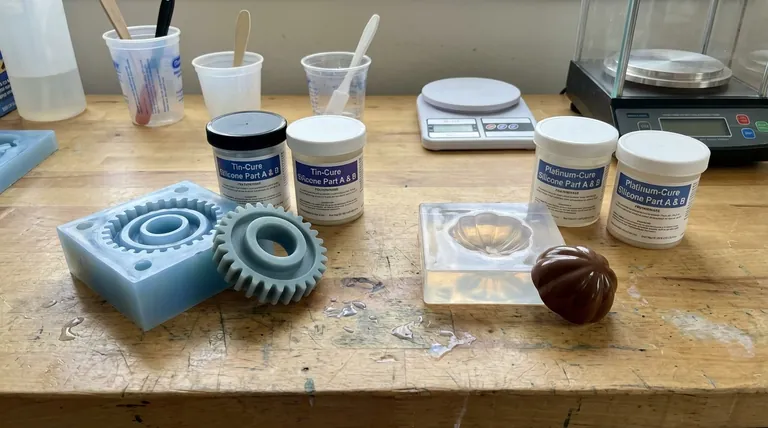

Tin-Cure Silicone: The General-Purpose Workhorse

Tin-cure silicones are a robust and widely used option for a variety of mold-making projects. Their name comes from the tin-salt catalyst used to initiate the curing process.

The Curing Mechanism: Polycondensation

This type of silicone cures through a polycondensation reaction. As the material cures, it releases a byproduct, typically a non-toxic alcohol. This process is highly reliable and less susceptible to environmental factors.

Key Characteristics

Tin-cure silicones are known for being more economical and forgiving. They are not easily affected by minor contaminants on the surface of the master model, making them a good choice for beginners.

Common Applications

Their durability and lower cost make them ideal for general-purpose molds, props, architectural reproductions, and casting resins like urethane, polyester, and epoxy.

Platinum-Cure Silicone: The Precision Instrument

Platinum-cure silicones represent a more advanced formulation, offering higher performance and purity. They rely on a platinum catalyst for their curing process.

The Curing Mechanism: Polyaddition

This silicone cures via a polyaddition reaction, which creates a direct chemical bond without producing any byproducts. This results in a more stable and precise final mold.

Key Characteristics

The primary advantages of platinum-cure silicones are their extremely low shrinkage, high-temperature resistance, and long-term dimensional stability. Certain formulations are certified as skin-safe or food-safe.

Common Applications

These properties make platinum-cure the standard for high-detail applications like medical prosthetics, special effects, food-grade molds for chocolate or baking, and high-precision parts for engineering.

Understanding the Critical Trade-offs

Choosing the wrong silicone can lead to costly and frustrating failures. The most critical difference to understand is platinum-cure's sensitivity to contamination.

The Challenge of Cure Inhibition

Cure inhibition is the single most common failure point for platinum-cure silicones. This occurs when the platinum catalyst comes into contact with certain chemicals, preventing the silicone from curing properly.

Common inhibitors include sulfur (found in some modeling clays), tin (from tin-cure silicones), latex, and certain 3D-printed resins. A contaminated model will leave the mold sticky and unusable at the point of contact.

Cost vs. Performance

There is a clear cost distinction. Tin-cure is significantly less expensive than platinum-cure. This makes it a practical choice for large-scale projects or applications where the highest precision is not required.

Shelf Life vs. Library Life

While tin-cure silicones have a good working shelf life, the molds themselves have a limited "library life." Over several years, they can continue to shrink and become brittle. Platinum-cure molds are archivally stable, exhibiting almost no change over decades.

How to Choose the Right Silicone for Your Project

Your project's specific requirements should be the sole guide for your decision.

- If your primary focus is cost-effective general molding: Tin-cure is your most reliable and forgiving choice.

- If your primary focus is food safety or skin contact: You must use a properly certified platinum-cure silicone.

- If your primary focus is high-precision and long-term stability: Platinum-cure's minimal shrinkage and archival quality are essential.

- If you are a beginner or unsure about contaminants: Tin-cure is less prone to inhibition and offers a higher chance of success.

Understanding these fundamental differences empowers you to select the right material, ensuring your project's success from the start.

Summary Table:

| Feature | Tin-Cure Silicone | Platinum-Cure Silicone |

|---|---|---|

| Curing Process | Polycondensation (releases alcohol) | Polyaddition (no byproducts) |

| Cost | Economical | Higher cost |

| Sensitivity | Forgiving, less prone to inhibition | Sensitive to contaminants (sulfur, tin) |

| Shrinkage & Stability | Higher shrinkage, limited library life | Low shrinkage, archivally stable |

| Common Uses | General molding, props, architectural | Food-safe, medical, high-precision parts |

Ready to select the perfect silicone for your project?

At KINTEK, we specialize in providing high-quality lab equipment and consumables, including the right silicone molding materials for your specific needs. Whether you're creating detailed prototypes, food-safe molds, or durable industrial parts, our experts can help you choose the ideal product to ensure success and efficiency in your laboratory.

Contact our team today for personalized advice and discover how KINTEK can support your innovation!

Visual Guide

Related Products

- Polygon Press Mold for Lab

- Square Lab Press Mold for Laboratory Applications

- Ball Press Mold for Lab

- Cylindrical Press Mold with Scale for Lab

- Assemble Lab Cylindrical Press Mold

People Also Ask

- What function do high-purity graphite molds serve during the hot-press sintering of LLZO? Optimize Energy Transfer

- What is a molding tool used for? A Guide to Mass Production Efficiency

- What functions do graphite molds perform? Critical Roles in Vacuum Hot-Pressing C_fiber/Si3N4 Composites

- Why apply Boron Nitride (BN) to graphite molds for titanium hot pressing? Enhance Purity and Release Efficiency

- What is a press mold in ceramics? A Tool for Consistent, Efficient Ceramic Production

- What role does a Boron Nitride (BN) sleeve play in cold sintering mold assemblies? Essential Electrical Insulation

- What is the function of two plate Mould? A Guide to Simple, Cost-Effective Injection Molding

- What dual role does the graphite mold play during the hot-pressing sintering process of W-Si alloy targets?