Yes, absolutely. Ceramic is not just a viable material for a crucible; it is one of the most common and effective choices for high-temperature applications. The term "ceramic" covers a wide range of materials, each engineered with specific properties that make them ideal for containing molten metals and other substances under extreme heat.

The critical question isn't if you can use a ceramic crucible, but which specific ceramic material is correct for your target temperature, the substance you are melting, and your heating method.

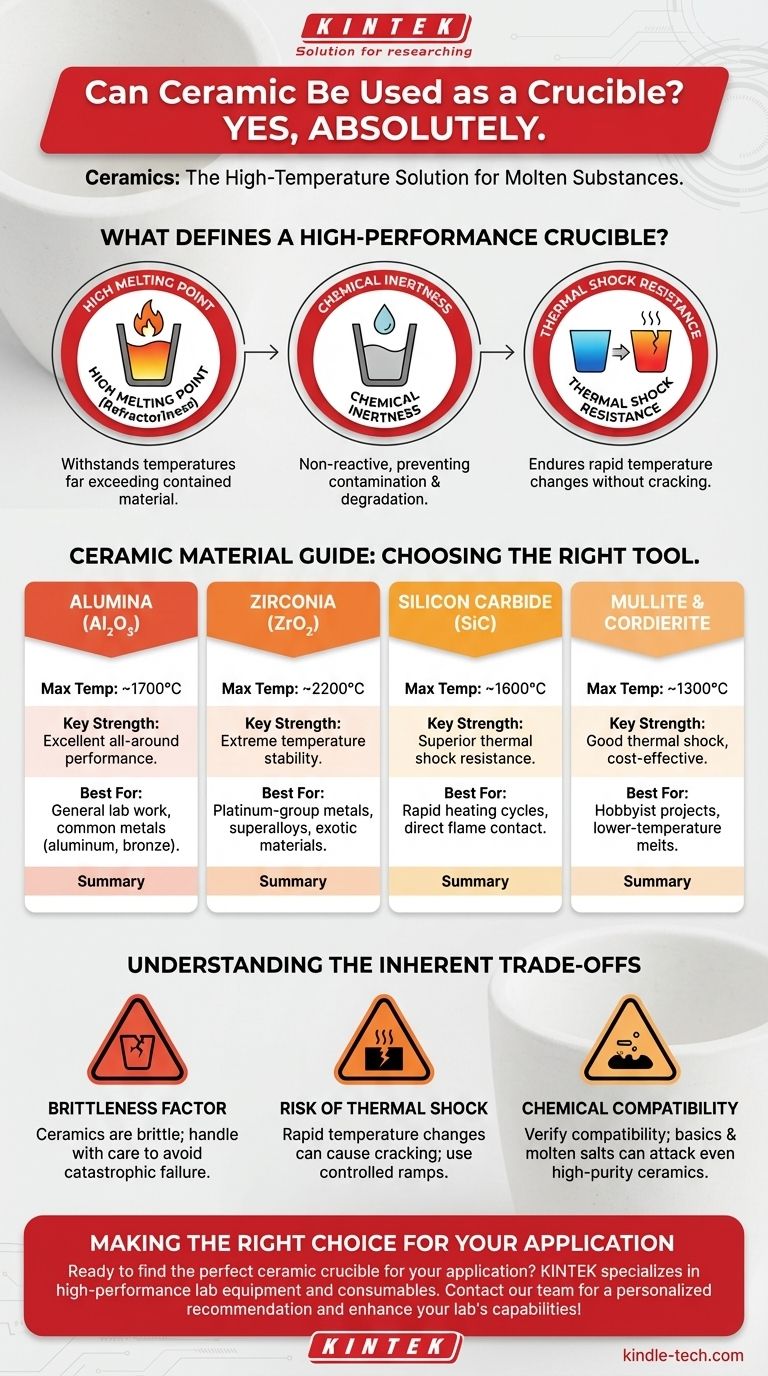

What Defines a High-Performance Crucible?

To understand why ceramics excel, we must first define the key properties a crucible needs to withstand the harsh environment of a furnace.

High Melting Point (Refractoriness)

A crucible's primary job is to remain solid and structurally sound at temperatures far exceeding the melting point of the material it holds. This property is known as refractoriness.

Chemical Inertness

The crucible must not react with the molten material inside it. Any chemical reaction can contaminate your sample and degrade the crucible itself, leading to failure.

Thermal Shock Resistance

A crucible must endure rapid temperature changes without cracking. The ability to move from room temperature to over 1000°C and back again is a crucial measure of its durability.

A Guide to Common Ceramic Crucible Materials

Not all ceramics are created equal. The right choice depends entirely on your specific application and budget.

Alumina (Aluminum Oxide, Al₂O₃)

Alumina is the industry workhorse. It offers an excellent balance of high-temperature stability (up to ~1700°C), chemical resistance, and reasonable cost. It is a reliable choice for melting a wide range of metals and glasses.

Zirconia (Zirconium Dioxide, ZrO₂)

When you need to work at extremely high temperatures (up to ~2200°C), Zirconia is the specialist. It has a very low chemical reactivity, making it ideal for melting superalloys, platinum-group metals, and other exotic materials.

Silicon Carbide (SiC)

The standout feature of Silicon Carbide is its exceptional thermal conductivity and thermal shock resistance. This makes it perfect for applications involving very rapid heating and cooling cycles where other ceramics might crack.

Mullite and Cordierite

These materials represent more budget-friendly options. While they don't reach the extreme temperatures of alumina or zirconia, they offer good thermal shock resistance and are suitable for many lower-temperature hobbyist or laboratory applications.

Understanding the Inherent Trade-offs

While ceramic crucibles are powerful tools, they are not without their limitations. Understanding these is key to using them successfully.

The Brittleness Factor

Ceramics are inherently brittle. Unlike metal crucibles (like steel or graphite), they cannot be dropped or mishandled without a high risk of catastrophic failure. They require careful handling at all times.

The Risk of Thermal Shock

Despite materials like SiC being designed for it, thermal shock remains the primary failure mode for most ceramic crucibles. Heating or cooling too quickly can create internal stresses that lead to cracks. A controlled, gradual temperature ramp is always the safest practice.

Chemical Compatibility

While generally inert, no ceramic is perfect. For example, highly basic slags or certain molten salts can attack even a high-purity alumina crucible over time. Always verify the compatibility of your crucible material with the specific substance you plan to melt.

Making the Right Choice for Your Application

Use your specific goal to guide your material selection.

- If your primary focus is general-purpose lab work or melting common metals like aluminum or bronze: High-purity Alumina is the most reliable and cost-effective starting point.

- If your primary focus is working at extreme temperatures (above 1800°C) or with highly reactive alloys: Zirconia is the necessary investment for purity and stability.

- If your primary focus involves rapid heating and direct flame contact: A clay-graphite or Silicon Carbide crucible is specifically engineered to resist the thermal shock that would destroy other ceramics.

Choosing the correct crucible is the foundation for a safe, successful, and repeatable high-temperature process.

Summary Table:

| Material | Max Temperature | Key Strength | Best For |

|---|---|---|---|

| Alumina (Al₂O₃) | ~1700°C | Excellent all-around performance | General lab work, common metals (aluminum, bronze) |

| Zirconia (ZrO₂) | ~2200°C | Extreme temperature stability | Platinum-group metals, superalloys |

| Silicon Carbide (SiC) | ~1600°C | Superior thermal shock resistance | Rapid heating cycles, direct flame |

| Mullite/Cordierite | ~1300°C | Good thermal shock, cost-effective | Hobbyist projects, lower-temperature melts |

Ready to find the perfect ceramic crucible for your application?

KINTEK specializes in high-performance lab equipment and consumables. Our experts will help you select the ideal crucible material—whether it's alumina for reliability, zirconia for extreme temperatures, or silicon carbide for thermal shock resistance—ensuring purity, safety, and repeatable results in your high-temperature processes.

Contact our team today for a personalized recommendation and enhance your lab's capabilities!

Visual Guide

Related Products

- Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

- Alumina Al2O3 Ceramic Crucible Semicircle Boat with Lid for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Alumina Al2O3 Ceramic Crucible for Laboratory Muffle Furnace

- Arc-Shaped Alumina Ceramic Crucible High Temperature Resistant for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Ceramics Alumina Crucibles (Al2O3) for Thermal Analysis TGA DTA

People Also Ask

- What is the crucible in an induction furnace? A Passive Container for Direct Metal Melting

- How do you take care of a crucible and cover? Ensure Accurate Results & Prevent Damage

- What are the 5 uses of crucible and cover? A Guide to High-Temperature Material Processing

- Why Use Alumina Crucibles for TGA of Bicyclic Carbonates? Ensure Data Purity & Chemical Inertness

- What are the advantages of a crucible furnace? Achieve Precision Melting for Labs & Small-Scale Production

- What is the purpose of using an alumina crucible with a lid for g-C3N4 synthesis? Optimize Your Nanosheet Production

- What is the best crucible made of? Match the Material to Your Metal for a Perfect Melt

- What is the role of grinding spent catalysts in a ceramic crucible? Unlock 99% Leaching Recovery Rates