Yes, in many cases, a ceramic crown can be repaired. Whether a repair is the right course of action depends heavily on the size, location, and nature of the damage. For small, cosmetic chips that do not affect the structural integrity of the crown or your bite, a dentist can often bond restorative material directly to the crown in a single visit.

While repairing a ceramic crown is a technically possible and often cost-effective solution for minor damage, it should be viewed as a compromise. The bond between the repair material and the crown is the weak point, making replacement the only truly permanent, long-term solution for restoring original strength and aesthetics.

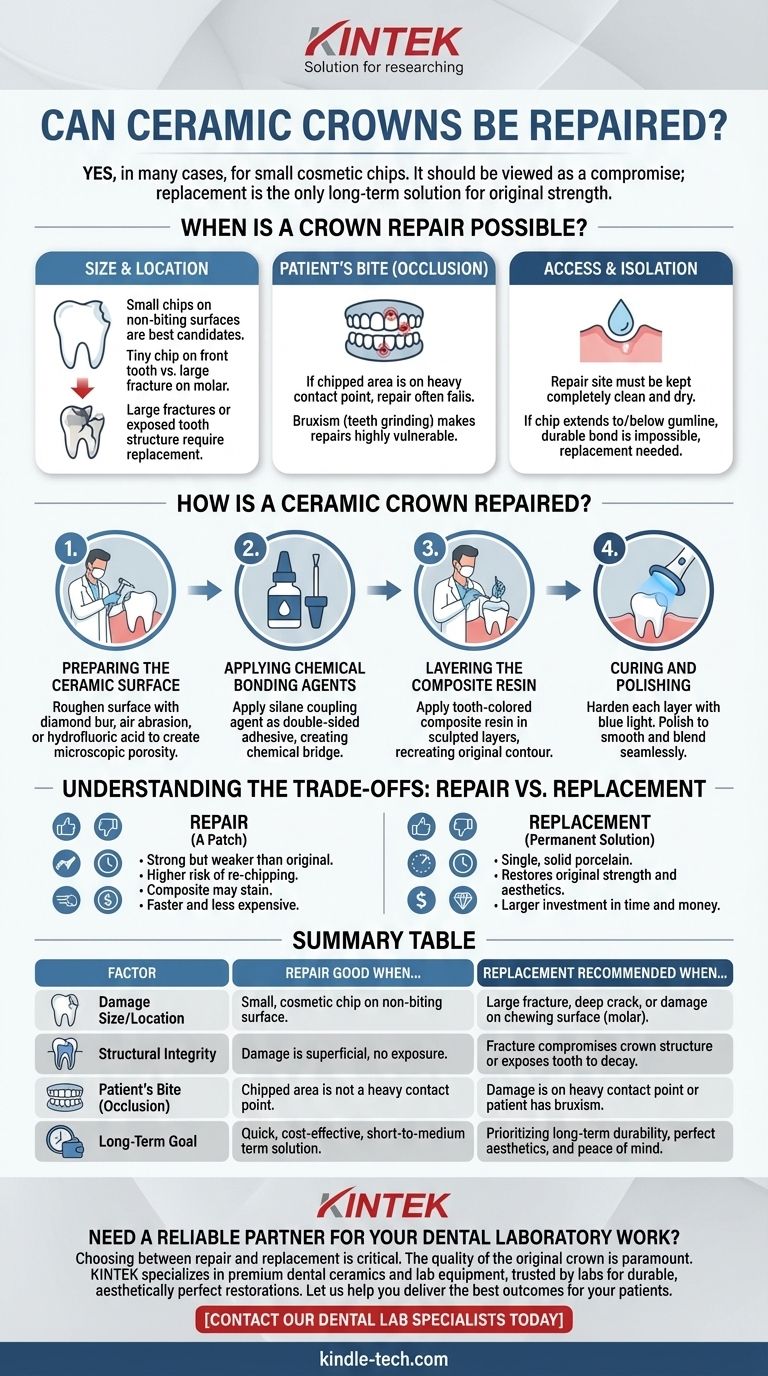

When is a Crown Repair Possible?

The decision to repair or replace a crown is a clinical judgment made by your dentist. It hinges on a few key factors that determine the potential for a successful, lasting repair.

The Size and Location of the Damage

Small chips, particularly on non-biting surfaces, are the best candidates for repair. A tiny chip on the side of a front tooth is much easier to fix than a large fracture on a molar that bears the full force of chewing.

If the fracture is large, deep, or exposes the underlying tooth structure, replacement is almost always necessary to prevent further damage or decay.

The Patient's Bite (Occlusion)

Your dentist will carefully examine how your teeth come together. If the chipped area is on a point of heavy contact when you bite or chew, a repair is much more likely to fail.

Patients who grind their teeth (a condition called bruxism) place extreme stress on all their dental work, making a repaired crown highly vulnerable to breaking again.

Access and Isolation

To create a strong bond, the repair site must be kept completely clean and dry. If the chip extends down to or below the gumline, it is very difficult to prevent contamination from saliva or moisture.

In these cases, a durable bond is nearly impossible to achieve, and a replacement is the only reliable option.

How is a Ceramic Crown Repaired?

The repair process is a meticulous, multi-step procedure that leverages modern dental bonding technology. It is very similar to getting a tooth-colored filling.

1. Preparing the Ceramic Surface

First, the dentist roughens the chipped porcelain surface. This is often done with a fine diamond bur, air abrasion (a "sandblaster" using fine particles), or the application of a special acid, typically hydrofluoric acid. This creates microscopic porosity, giving the bonding material something to grip.

2. Applying Chemical Bonding Agents

This is the most critical step. A silane coupling agent is applied to the etched ceramic. This chemical acts as a double-sided adhesive, creating a strong chemical bridge between the inorganic ceramic and the organic composite resin that will be used for the repair.

3. Layering the Composite Resin

The dentist then applies a tooth-colored composite resin—the same material used for modern fillings—in small, carefully sculpted layers. They will match the shade to your crown and build the material up to recreate the original contour of the tooth.

4. Curing and Polishing

Each layer of composite is hardened, or "cured," using a high-intensity blue light. Once the final shape is achieved, the dentist uses a series of fine polishing discs and pastes to smooth the repair until it blends seamlessly with the crown and feels imperceptible to your tongue.

Understanding the Trade-offs: Repair vs. Replacement

Choosing between repair and replacement involves weighing short-term convenience against long-term reliability.

Durability and Longevity

A repair is fundamentally a patch. The bond between the composite and the ceramic is strong, but it is not as strong as a single, solid piece of porcelain. A repaired crown will always have a higher risk of chipping or breaking again compared to a new crown.

Aesthetics and Staining

While a fresh repair can look excellent, the composite resin material may stain at a different rate than the ceramic crown over the years. Over time, a faint line or a slight color mismatch can develop at the margin of the repair.

Cost and Time

A repair is significantly faster and less expensive than a replacement. It is a single-visit procedure that avoids the need for impressions, a temporary crown, and laboratory fabrication costs. A full replacement is a larger investment in both time and money.

Making the Right Choice for Your Situation

Your dentist will provide a recommendation based on their clinical assessment. However, understanding these principles can help you have a more informed discussion about your priorities.

- If your primary focus is a quick, low-cost fix for a minor cosmetic chip: A repair is an excellent and practical option to restore aesthetics and function in the short term.

- If your primary focus is long-term durability and peace of mind: Replacing the crown is the definitive solution, especially if the damage is significant, affects your bite, or is on a molar.

- If your primary focus is perfect aesthetics on a highly visible front tooth: While a repair can look good initially, replacement is the only way to guarantee a seamless, stable color match for years to come.

Ultimately, a detailed examination by your dental professional is the crucial first step toward choosing the best path forward for a healthy and confident smile.

Summary Table:

| Factor | Repair is a Good Option When... | Replacement is Recommended When... |

|---|---|---|

| Damage Size/Location | Small, cosmetic chip on a non-biting surface. | Large fracture, deep crack, or damage on a chewing surface (molar). |

| Structural Integrity | Damage is superficial and does not expose the underlying tooth. | Fracture compromises the crown's structure or exposes the tooth to decay. |

| Patient's Bite (Occlusion) | The chipped area is not a point of heavy contact. | The damage is on a point of heavy contact or the patient has bruxism (teeth grinding). |

| Long-Term Goal | Seeking a quick, cost-effective, short-to-medium term solution. | Prioritizing long-term durability, perfect aesthetics, and peace of mind. |

Need a Reliable Partner for Your Dental Laboratory Work?

Choosing between repair and replacement is a critical decision for patient care. The quality and precision of the original crown are paramount for long-term success.

KINTEK specializes in premium dental ceramics and lab equipment, trusted by dental laboratories to create durable, aesthetically perfect restorations. Whether you're fabricating a new crown or need consistent, high-quality materials for repairs, we provide the tools and support for excellence.

Let us help you deliver the best outcomes for your patients.

Contact our dental lab specialists today to discuss how our solutions can enhance your practice's capabilities.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Dental Porcelain Sintering Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- What is the sintering temperature of zirconium? A Guide to the 1400°C-1600°C Range for Dental Labs

- What is one of the newest applications for dental ceramics? Monolithic Zirconia for Full-Arch Bridges

- What is the price of zirconia sintering furnace? Invest in Precision, Not Just a Price Tag

- What is a dental oven? The Precision Furnace for Creating Strong, Aesthetic Dental Restorations

- What is the effect of zirconia sintering temperature? Master the Key to Strength and Stability