Yes, absolutely. An induction furnace is not only capable of melting copper but is a common and efficient method for doing so. This technology is widely used for a variety of non-ferrous metals, including copper and its alloys like brass and bronze, as well as ferrous metals such as iron and steel.

The question is not if an induction furnace can melt copper, but rather which type and size of furnace is appropriate for your specific needs. The technology's core principle is highly effective for copper, offering precise control and high temperatures.

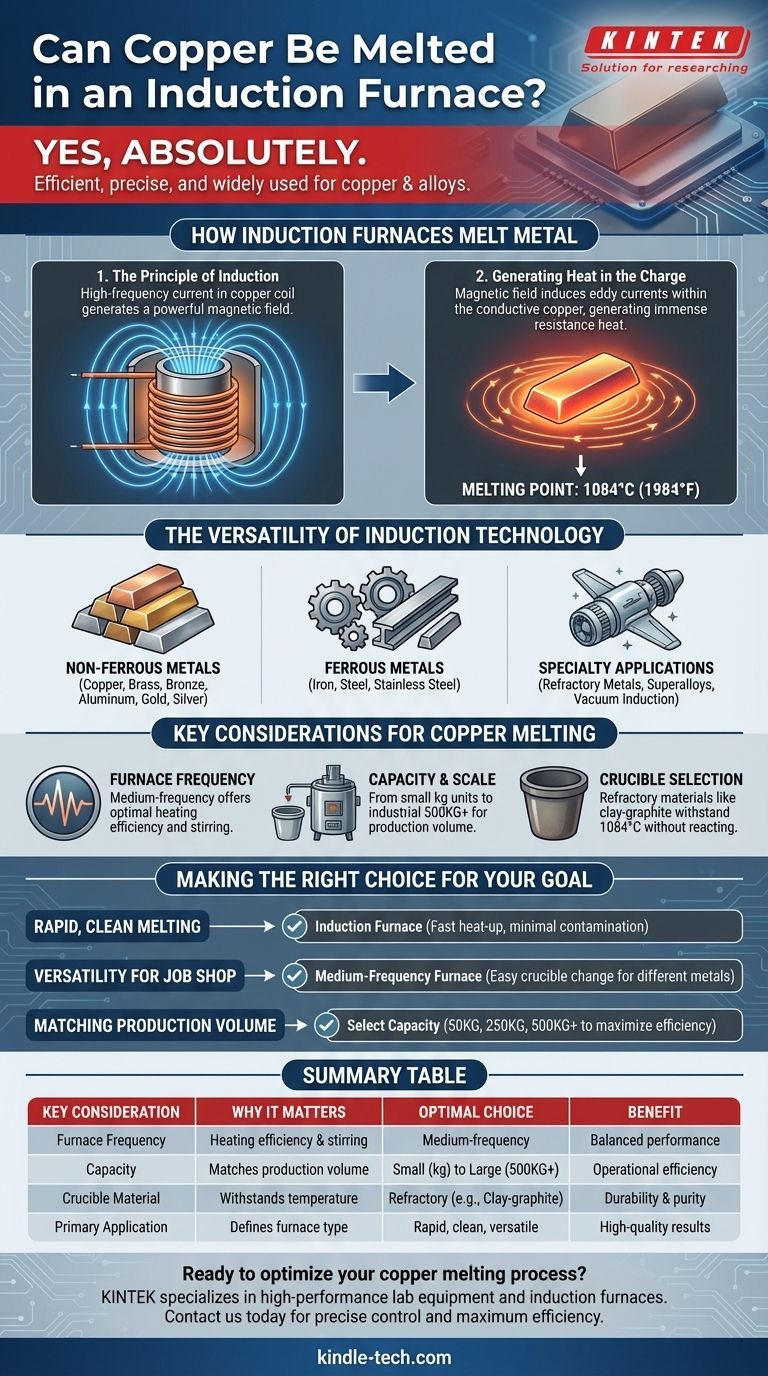

How Induction Furnaces Melt Metal

The Principle of Induction

An induction furnace operates without direct flame or contact heating elements. It uses a principle called electromagnetic induction.

A high-frequency electrical current is passed through a copper coil, which generates a powerful and rapidly changing magnetic field around the furnace's crucible.

Generating Heat in the Charge

When conductive material, such as copper scrap or ingots, is placed inside the crucible, this magnetic field induces strong electrical currents (known as eddy currents) within the metal itself.

The metal's natural electrical resistance causes these eddy currents to generate immense heat, rapidly raising the material's temperature to its melting point and beyond.

The Versatility of Induction Furnaces

One of the primary advantages of induction technology is its ability to melt a wide spectrum of materials efficiently.

Non-Ferrous Metals

Induction furnaces are a standard choice for melting non-ferrous metals. This includes pure copper, copper-based alloys like brass and bronze, as well as aluminum, gold, and silver.

Ferrous Metals and Alloys

The same furnaces, often with different parameters or crucible types, are used extensively for melting iron, carbon steel, stainless steel, and various complex alloys.

High-Temperature and Specialty Applications

The technology can achieve extremely high temperatures, making it suitable for melting refractory metals with very high melting points. Specialized vacuum induction furnaces are also used to produce high-purity superalloys for aerospace and other critical applications.

Understanding the Key Considerations for Copper

While the process is straightforward, certain factors are critical for an efficient and successful copper melting operation.

Furnace Frequency

Induction furnaces are often categorized by their operating frequency. For copper, medium-frequency induction furnaces are a common and effective choice, offering a good balance of heating efficiency and molten metal stirring action.

Capacity and Scale

The physical size of the furnace must match the intended workload. Furnaces for melting copper can range from small tabletop units with a capacity of just a few kilograms to large industrial models capable of melting up to 500KG or more per batch.

Crucible Selection

The molten copper is contained within a crucible. This component must be made from a refractory material, like clay-graphite or silicon carbide, that can withstand copper's melting temperature (1084°C or 1984°F) without cracking or reacting with the molten metal.

Making the Right Choice for Your Goal

To select the correct setup, you must first define your primary objective.

- If your primary focus is rapid, clean melting with precise control: An induction furnace is an excellent choice for copper, as it provides fast heat-up times and minimizes contamination compared to fuel-fired methods.

- If your primary focus is versatility for a job shop: A medium-frequency furnace is ideal, as it can efficiently melt copper-based alloys one day and switch to melting steel or aluminum the next with a simple change of crucible.

- If your primary focus is matching a specific production volume: Ensure you select a furnace with a melting capacity (e.g., 50KG, 250KG, 500KG) that aligns with your throughput requirements to maximize operational efficiency.

Ultimately, an induction furnace is a powerful and reliable tool for melting copper for nearly any application.

Summary Table:

| Key Consideration | Why It Matters for Copper Melting |

|---|---|

| Furnace Frequency | Medium-frequency furnaces offer optimal heating efficiency and metal stirring. |

| Capacity | Choose from small (kg) to industrial (500KG+) units to match your production volume. |

| Crucible Material | Requires refractory materials (e.g., clay-graphite) to withstand 1084°C+ temperatures. |

| Primary Application | Ideal for rapid, clean melting, versatility across metals, and high-purity results. |

Ready to optimize your copper melting process? KINTEK specializes in high-performance lab equipment and consumables, providing reliable induction furnaces tailored for laboratory and small-scale production needs. Whether you're melting copper, brass, bronze, or other metals, our solutions ensure precise temperature control, minimal contamination, and maximum efficiency. Contact us today to discuss your specific requirements and discover how our expertise can enhance your operations!

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vertical Laboratory Tube Furnace

People Also Ask

- What is the process of melting in an induction furnace? Harnessing Electromagnetic Power for Efficient Metal Melting

- What is the primary function of a high-frequency induction melting furnace for CuNi alloys? Achieve Atomic Homogeneity

- What are the disadvantages of direct core type induction furnace? High Standby Costs and Inflexibility

- Does induction heating work on gold? The Ultimate Guide to Fast, Efficient Gold Melting

- What are the basics of induction melting? A Guide to Fast, Clean Metal Processing

- What are the disadvantages of a coreless induction furnace? Key Limitations in Efficiency and Refining

- How do high-temperature melting furnaces ensure the bioactivity of materials? Achieve Precise Bioactive Glass Coatings

- What are the common applications of a vacuum induction melting furnace? Produce High-Purity Metals for Demanding Industries