While technically possible in some limited scenarios, the professional standard and strong recommendation is to never use the same crucible for different types of metals. Doing so introduces an unacceptable risk of cross-contamination, which can ruin the integrity of your melts, lead to failed castings, and create unpredictable results. A dedicated crucible for each metal type is a fundamental principle of sound foundry practice.

The core issue isn't cleanliness, but chemistry. Molten metals are absorbed into the microscopic pores of the crucible wall, and this residue will leach out and contaminate subsequent, different melts, permanently altering their properties.

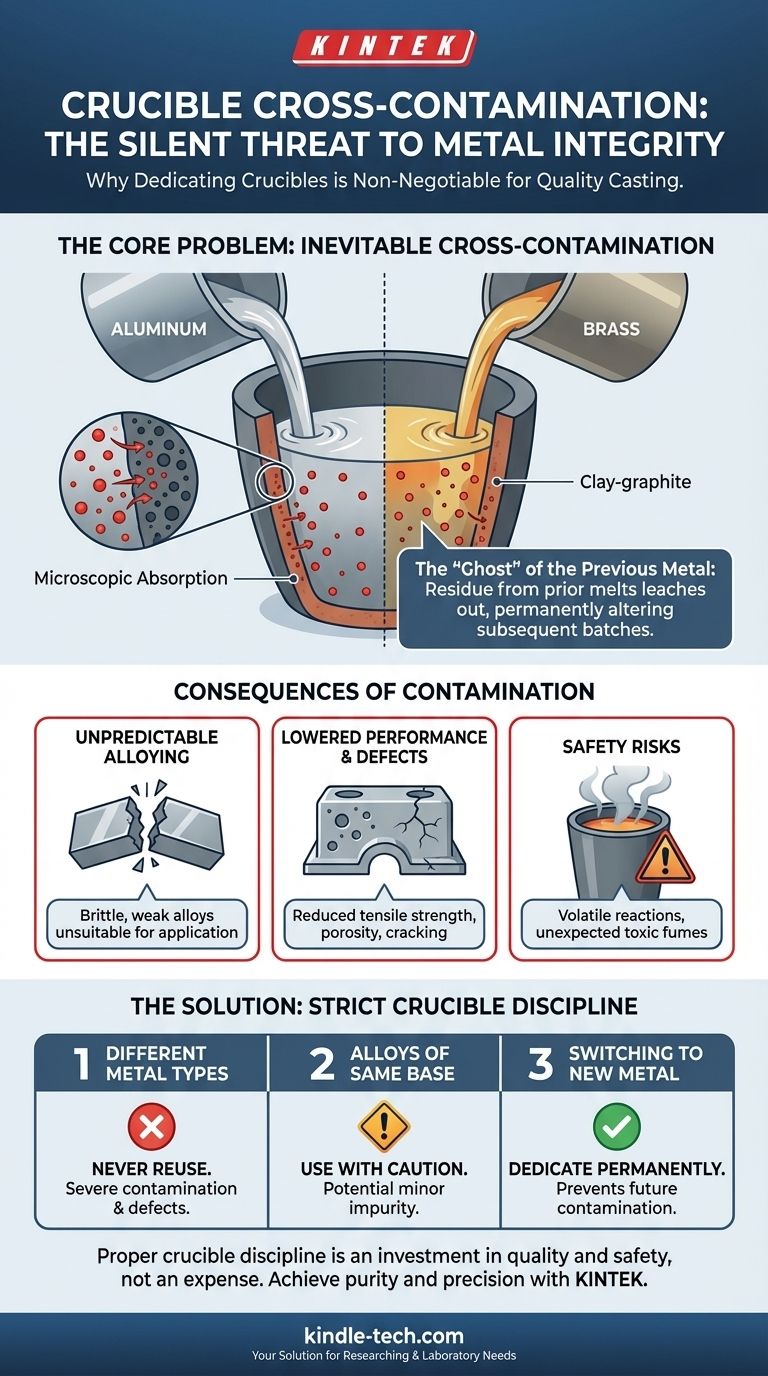

The Core Problem: Inevitable Cross-Contamination

When you melt metal, the crucible doesn't just act as a simple container. It becomes an active part of the high-temperature environment, leading to a situation where residue is impossible to fully remove.

Microscopic Absorption

Crucibles, particularly common clay-graphite models, are porous materials. At extreme temperatures, a small amount of the molten metal will seep into the pores of the crucible's interior wall.

The "Ghost" of the Previous Metal

No amount of scraping, cleaning, or re-firing can completely remove this absorbed metal. When you introduce a new, different metal, the residue from the previous melt—the "ghost"—will leach out and mix with your new batch.

How Contamination Compromises Your Metal

Even a tiny amount of a foreign metal can have a dramatic and detrimental effect on the chemical and physical properties of your intended alloy. This is not a minor issue; it is the primary reason for dedicating crucibles.

Unpredictable Alloying

The most significant danger is creating an unintended and weak alloy. For example, a small amount of zinc left over from melting brass can contaminate a subsequent aluminum melt. This makes the aluminum brittle and completely unsuitable for most applications.

Lowered Performance and Casting Defects

Contamination can lower the melting point, reduce tensile strength, and inhibit proper crystallization. This often manifests as casting defects like porosity, poor surface finish, or a higher likelihood of the final piece cracking under stress.

Safety Risks

In extreme cases, mixing incompatible metals can create volatile reactions or release toxic fumes beyond what is normally expected for a given metal.

Understanding the Trade-offs and Common Pitfalls

The motivation to reuse a crucible for different metals almost always comes down to saving money or space. However, this is a classic example of a false economy.

The True Cost of a Failed Casting

A single crucible might cost $30 to $100. The cost of your time, fuel, and the metal used in a single melt that fails due to contamination will almost always exceed the price of a new, dedicated crucible.

The Myth of "Cleaning It Out"

A common mistake for beginners is believing they can simply melt out the residue or scrape the crucible clean. As explained, the problem is absorption, not just surface residue. You cannot scrape out the metal that has soaked into the crucible wall itself.

Contamination is a One-Way Street

Once a crucible has been used for a "dirty" metal like zinc or lead, it should be considered permanently contaminated. You can never safely return to melting a high-purity metal like aluminum or silver in that same crucible.

Making the Right Choice for Your Goal

Adopting a strict crucible management policy is the foundation for achieving consistent, high-quality results in metal casting. Label your crucibles clearly with a high-temperature marker or paint.

- If your primary focus is high-quality, predictable results: Absolutely dedicate one crucible for each distinct metal type you work with (e.g., one for aluminum, one for bronze, one for silver).

- If you work with different alloys of the same base metal: You can often use the same crucible for similar alloys (e.g., switching between 6061 and 356 aluminum), but best practice is still to keep them separate if alloy purity is critical.

- If you absolutely must switch to a new metal type: Consider the existing crucible permanently dedicated to that new metal from that point forward, and never go back to the original.

Proper crucible discipline is not an expense; it is an investment in the quality and safety of your work.

Summary Table:

| Scenario | Recommendation | Key Risk |

|---|---|---|

| Different Metal Types (e.g., Aluminum to Brass) | Never Reuse | Severe contamination, brittle alloys, casting defects |

| Alloys of Same Base Metal (e.g., 6061 to 356 Aluminum) | Use with Caution | Potential for minor alloy impurity |

| Switching to a New Metal Type | Dedicate Crucible Permanently | Prevents future contamination |

Achieve Purity and Precision in Every Melt with KINTEK

Don't let cross-contamination compromise your lab results or production quality. KINTEK specializes in high-performance lab equipment and consumables, including a full range of dedicated crucibles designed for specific metals and alloys.

By using the right crucible for each application, you ensure:

- Metal Integrity: Guarantee the chemical composition and properties of your melts.

- Consistent Results: Eliminate variables for reliable, repeatable outcomes.

- Enhanced Safety: Avoid unpredictable reactions and toxic fume risks.

Our experts can help you select the perfect crucible for your specific metals and processes. Contact KINTEK today to discuss your laboratory needs and protect your investments.

Visual Guide

Related Products

- Custom Machined and Molded PTFE Teflon Parts Manufacturer with PTFE Crucible and Lid

- Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

- Arc-Shaped Alumina Ceramic Crucible High Temperature Resistant for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Ceramics Alumina Crucibles (Al2O3) for Thermal Analysis TGA DTA

- Engineering Advanced Fine Alumina Al2O3 Ceramic Crucible for Laboratory Muffle Furnace

People Also Ask

- What is a crucible material for a furnace? A Guide to Choosing the Right High-Temperature Container

- Why is a PTFE crucible preferred for plasma etching? Ensure Chemical Integrity and Targeted Action

- What is the best type of crucible? The Answer Depends on Your Application's Needs

- What are crucibles used for in lab? Ensuring Accurate, High-Temperature Sample Analysis

- What is the most durable crucible? Match the Right Crucible to Your Melting Application