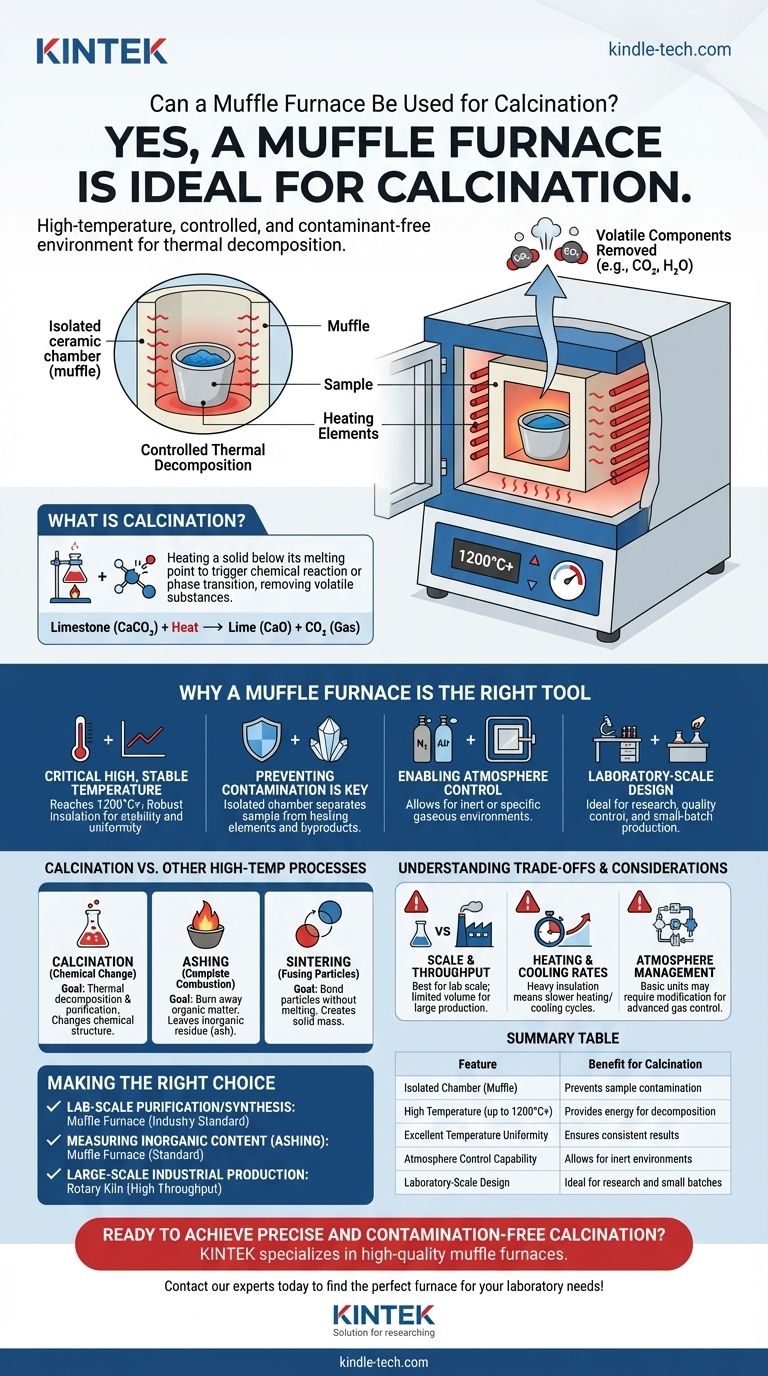

Yes, a muffle furnace is an ideal and commonly used piece of equipment for calcination. This type of furnace excels at providing the high-temperature, controlled, and contaminant-free environment required to thermally decompose materials, drive off volatile components, and induce chemical or physical changes in a sample.

The core reason a muffle furnace is perfect for calcination is its "muffle," or isolated chamber, which separates the material being heated from the heating elements. This design ensures precise temperature control and prevents contamination, which is critical for the purification and decomposition reactions central to the calcination process.

What is Calcination and Why is a Muffle Furnace the Right Tool?

Understanding the calcination process itself clarifies why the features of a muffle furnace are so well-suited for the task. It's not just about heating; it's about controlled thermal decomposition.

Defining the Process: More Than Just Heating

Calcination is the process of heating a solid material to a high temperature, below its melting point, in the absence or limited supply of air. The primary goal is to trigger a chemical reaction or phase transition, most often to remove volatile substances like bound water or carbon dioxide.

A classic example is converting limestone (calcium carbonate, CaCO₃) into lime (calcium oxide, CaO) by heating it to drive off carbon dioxide (CO₂).

The Critical Role of High, Stable Temperature

Calcination reactions require specific, often very high, temperatures to proceed efficiently. Muffle furnaces are designed to reach and maintain temperatures up to 1200°C or higher, providing the thermal energy needed for these transformations.

Their robust insulation ensures excellent temperature stability and uniformity throughout the chamber, leading to consistent and predictable results.

Preventing Contamination is Key

The defining feature of a muffle furnace is that the sample is physically isolated from the heating elements and any products of combustion.

This is crucial for calcination, where the purity of the final product is often the primary goal. The muffle design ensures that byproducts from the heating source do not react with or contaminate the sample.

Enabling Atmosphere Control

Because the chamber is sealed and isolated, it allows for control over the gaseous environment. While many calcination processes are done in ambient air, the setup makes it possible to introduce specific gases (like nitrogen) to create an inert atmosphere for sensitive materials.

Calcination vs. Other High-Temperature Processes

Muffle furnaces are used for several high-temperature applications that sound similar but have distinct goals. Understanding the difference highlights the specific function of calcination.

Calcination: Driving Chemical Change

The purpose of calcination is thermal decomposition and purification. The goal is to change the chemical structure of the material itself by removing specific volatile components.

Ashing: Complete Combustion

The purpose of ashing is to burn away all organic matter to determine the amount of non-combustible, inorganic residue (ash) left behind. It is a process of complete removal, often for analytical purposes.

Sintering: Fusing Particles Together

The purpose of sintering is to bond particles into a solid mass without melting them. Heat and pressure cause the atoms in the powder to diffuse across boundaries, creating a single solid piece, as is done in the manufacturing of ceramics.

Understanding the Trade-offs and Considerations

While ideal for the task, there are practical considerations to keep in mind when using a muffle furnace for calcination.

Scale and Throughput

Muffle furnaces are best suited for laboratory-scale research, quality control, and small-batch production. Their size inherently limits the volume of material that can be processed at one time. For large-scale industrial production, a rotary kiln is the more common equipment.

Heating and Cooling Rates

The heavy ceramic insulation that makes muffle furnaces so stable and efficient also means they heat up and cool down relatively slowly. This must be factored into the total processing time.

Atmosphere Management

While the design enables atmosphere control, a basic muffle furnace may not come equipped with the ports and flow controllers needed for sophisticated gas management. This capability often requires a more specialized or modified unit.

Making the Right Choice for Your Goal

To determine if a muffle furnace is the correct tool, consider your final objective.

- If your primary focus is laboratory-scale material purification or synthesis: A muffle furnace is the industry-standard tool, providing the precise heat and contaminant-free environment required for calcining small batches.

- If your primary focus is to measure the inorganic content of a sample: You are likely performing ashing, a related process for which muffle furnaces are also the standard equipment.

- If your primary focus is large-scale industrial production: A muffle furnace is excellent for developing the process parameters, but a rotary kiln or similar industrial furnace will be needed to achieve high throughput.

Ultimately, the muffle furnace's ability to deliver precise and isolated high-temperature treatment makes it a cornerstone of thermal processing, with calcination being one of its most fundamental applications.

Summary Table:

| Feature | Benefit for Calcination |

|---|---|

| Isolated Chamber (Muffle) | Prevents sample contamination from heating elements |

| High Temperature (up to 1200°C+) | Provides energy for thermal decomposition reactions |

| Excellent Temperature Uniformity | Ensures consistent and predictable results |

| Atmosphere Control Capability | Allows for inert environments if needed |

| Laboratory-Scale Design | Ideal for research, quality control, and small batches |

Ready to achieve precise and contamination-free calcination in your lab? KINTEK specializes in high-quality muffle furnaces designed for reliable thermal processing like calcination and ashing. Our equipment ensures the temperature control and purity your research demands. Contact our experts today to find the perfect furnace for your laboratory needs!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What causes increase in ash content? Uncover the hidden culprits that harm your equipment.

- What precautions should be taken while heating and cooling the crucible? Prevent Thermal Shock and Ensure Safety

- What is the body structure of a furnace? Unlocking the Dual-Layer Design for Superior Thermal Control

- What is the optimal temperature for ashing in a muffle furnace? Achieve Precise and Efficient Results

- What are the disadvantages of wet ashing? Key Safety & Contamination Risks