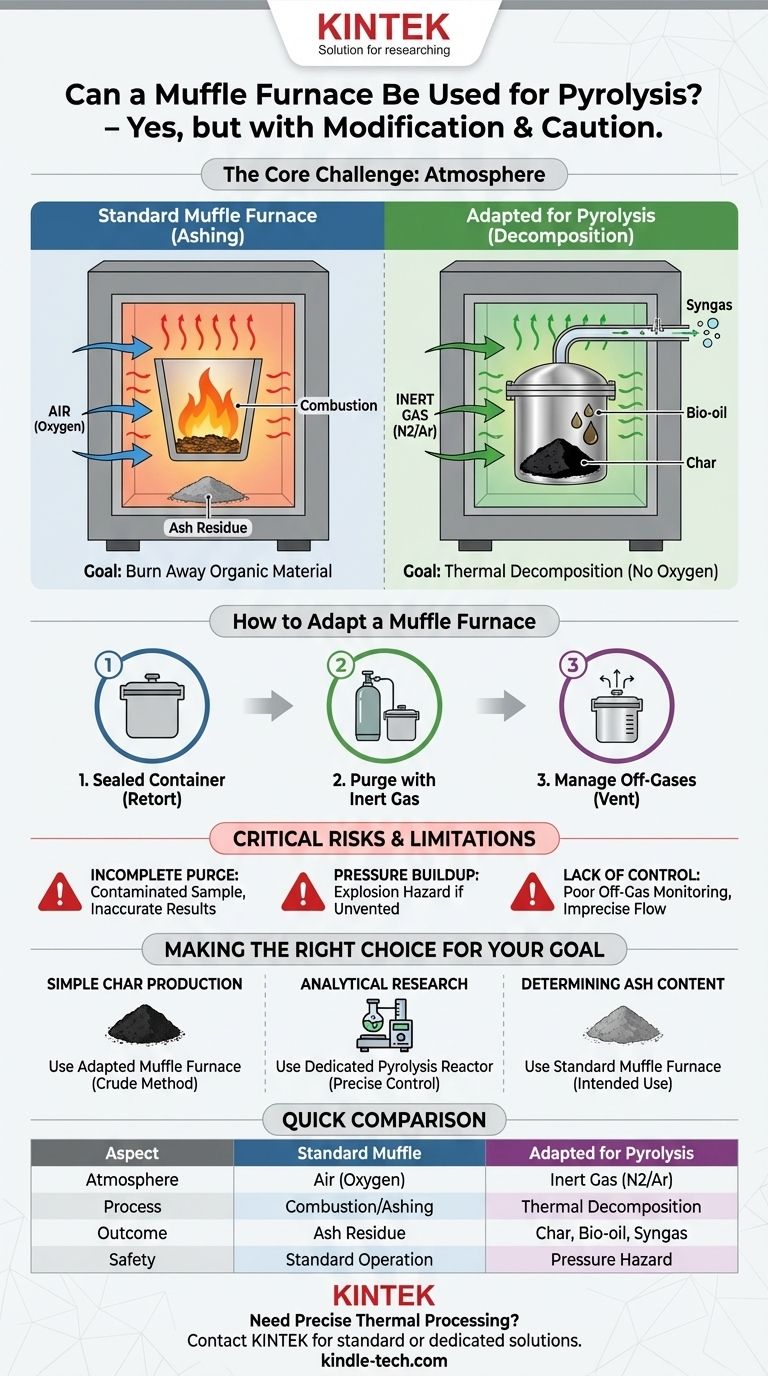

While a standard muffle furnace is not directly designed for pyrolysis, it can be adapted for this purpose by creating a controlled, oxygen-free environment within its heating chamber. A typical muffle furnace heats samples in the presence of air, leading to combustion or ashing. To achieve pyrolysis, you must isolate the sample from oxygen, typically by using a sealed retort that has been purged with an inert gas.

The core issue is the atmosphere inside the furnace. Standard muffle furnace operation uses air (with oxygen) to achieve ashing, while true pyrolysis requires an inert atmosphere (without oxygen) for thermal decomposition. Without this modification, you will be performing combustion, not pyrolysis.

Understanding the Fundamental Difference: Pyrolysis vs. Ashing

The terms pyrolysis, ashing, and combustion are often used in the context of high-temperature heating, but they describe fundamentally different chemical processes distinguished by the presence or absence of oxygen.

What is Pyrolysis?

Pyrolysis is the thermal decomposition of materials at elevated temperatures in an anoxic (oxygen-free) atmosphere.

Instead of burning, the material breaks down into other products. For organic materials, these products are typically a solid residue (char), a liquid (bio-oil), and various gases (syngas).

How a Standard Muffle Furnace Works

A muffle furnace is an oven designed for high-temperature applications, often reaching 1200°C or more. Its core function is to heat a sample uniformly to a set temperature.

Crucially, a standard muffle furnace's chamber is filled with ambient air. When organic material is heated in the presence of oxygen, it combusts, or burns. This is the process used for ashing, where the goal is to burn away all organic material to measure the non-combustible inorganic residue.

The Critical Role of the Atmosphere

The atmosphere determines the outcome of heating organic matter.

- Heating in Air (Oxygen): Leads to combustion and ashing.

- Heating in an Inert Gas (Nitrogen, Argon): Leads to pyrolysis.

Therefore, using a standard muffle furnace without modification will result in your sample burning away, which is the opposite of the goal of pyrolysis.

How to Adapt a Muffle Furnace for Pyrolysis

To perform pyrolysis in a muffle furnace, you must create a secondary, oxygen-free environment inside the main heating chamber.

The Sealed Container Method

The most common method is to place your sample inside a sealed container or retort made of a material that can withstand the target temperature, such as stainless steel or a ceramic crucible with a tight-fitting lid.

This container isolates the sample from the air inside the furnace chamber.

Purging with an Inert Gas

Simply sealing the container is often not enough, as it will still trap air inside with the sample.

For true pyrolysis, this container must be purged with an inert gas, such as nitrogen or argon, before being sealed and heated. This involves flowing the gas through the container to displace all the oxygen. In more advanced setups, a slow, continuous flow of inert gas is maintained throughout the process.

Managing Off-Gases

As pyrolysis occurs, it generates significant amounts of gas and vapor, which increases the pressure inside the sealed container.

The container must have a vent or pressure relief mechanism to allow these gases to escape safely. Otherwise, the pressure buildup could cause the container to rupture or explode, posing a serious safety hazard.

Understanding the Trade-offs and Risks

While adapting a muffle furnace is possible, it comes with significant limitations and risks compared to using a dedicated pyrolysis reactor.

Risk of Incomplete Purging

If oxygen is not completely removed from your sealed container, you will get a mixture of pyrolysis and combustion. This will contaminate your char sample and produce inaccurate results.

Pressure Buildup and Safety

Heating a fully sealed, unvented container is extremely dangerous. The pressure from the off-gases can cause a catastrophic failure. Any DIY retort must be designed to handle both the temperature and the pressure.

Lack of Process Control

This makeshift approach offers poor control. You cannot easily monitor the composition of the off-gases or precisely control the flow rate of the purge gas, which are critical parameters in analytical pyrolysis. A dedicated tube furnace or pyrolysis reactor is designed for this level of control.

Making the Right Choice for Your Goal

To decide on the correct approach, you must be clear about your objective.

- If your primary focus is simple char production: Using a properly vented, sealed container inside a muffle furnace can be a viable, if crude, method for creating a solid char residue.

- If your primary focus is analytical research: A dedicated tube furnace or pyrolysis reactor is essential for the atmospheric control, temperature precision, and off-gas analysis required for reliable data.

- If your primary focus is determining ash content: A standard muffle furnace operating in air is the correct and intended tool for the job.

Understanding the critical role of the atmosphere is the key to using your thermal equipment correctly and safely.

Summary Table:

| Aspect | Standard Muffle Furnace | Adapted for Pyrolysis |

|---|---|---|

| Atmosphere | Air (with oxygen) | Inert gas (nitrogen/argon) |

| Process | Combustion/Ashing | Thermal decomposition |

| Sample Outcome | Ash residue | Char, bio-oil, syngas |

| Safety Consideration | Standard operation | Pressure buildup risk |

| Best For | Ash content determination | Simple char production |

Need precise thermal processing for your lab? KINTEK specializes in lab equipment and consumables, offering both standard muffle furnaces for ashing and dedicated pyrolysis systems for advanced research. Our experts can help you choose the right solution to ensure safety, accuracy, and efficiency in your thermal decomposition experiments. Contact us today to discuss your specific laboratory requirements!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What are the environmental impacts of metal processing? A Guide to Sustainability and Solutions

- What are the stages of melting metal? Mastering the 3-Step Process from Solid to Liquid

- What is a muffle furnace used for? Achieve Pure, High-Temperature Processing

- What are the precautions for heat in the laboratory? Essential Safety Rules to Prevent Burns and Fires

- What are the safety precautions for heat experiment? Essential Steps to Prevent Lab Burns and Accidents