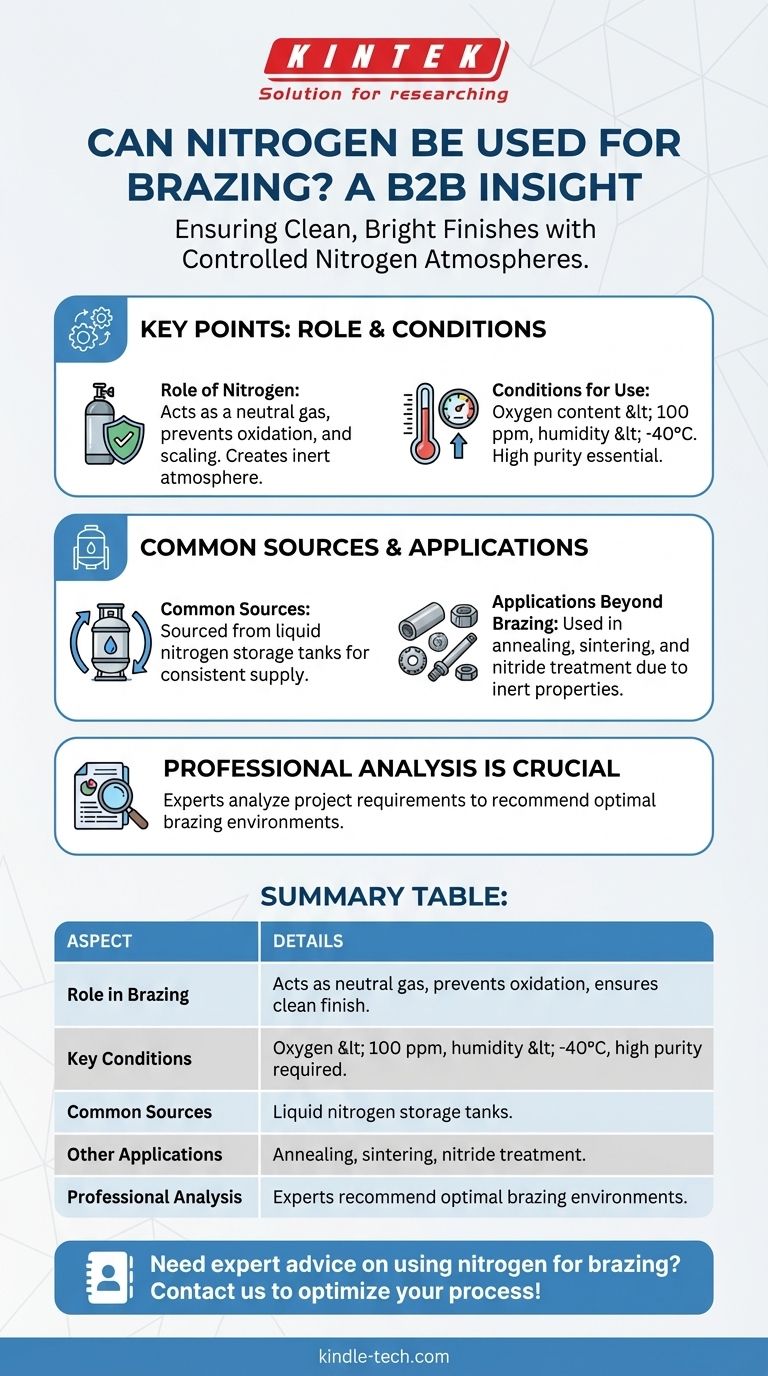

Nitrogen can indeed be used for brazing, but its suitability depends on specific conditions and requirements. Brazing requires an atmosphere devoid of oxidants, oxygen, and water, and nitrogen, when pure and properly controlled, can serve as a neutral gas for this purpose. It must meet strict criteria, such as oxygen content below 100 ppm and humidity below -40°C, to prevent oxidation and ensure a clean, bright finish. Nitrogen is commonly sourced from liquid nitrogen storage tanks and is widely used in various heat treatment processes, including brazing, due to its inert properties.

Key Points Explained:

-

Role of Nitrogen in Brazing:

- Nitrogen acts as a neutral gas in brazing, preventing oxidation and scaling by creating an inert atmosphere.

- It is particularly effective when the oxygen content is kept below 100 ppm and humidity is controlled to below -40°C.

-

Conditions for Using Nitrogen:

- The brazing environment must be free of oxidants, oxygen, and water to ensure a clean and bright finish.

- Nitrogen must be of high purity to meet the stringent requirements of brazing processes.

-

Common Sources of Nitrogen:

- Nitrogen is often sourced from liquid nitrogen storage tanks, which provide a reliable and consistent supply for brazing furnaces.

-

Applications Beyond Brazing:

- Nitrogen is widely used in other metal heat treatment processes, such as annealing, sintering, and nitride treatment, due to its inert properties.

-

Importance of Professional Analysis:

- Experienced brazing providers analyze project requirements to recommend the appropriate brazing environment, ensuring optimal results.

By understanding these key points, equipment and consumable purchasers can make informed decisions about using nitrogen for brazing and other heat treatment processes.

Summary Table:

| Aspect | Details |

|---|---|

| Role in Brazing | Acts as a neutral gas, prevents oxidation, and ensures a clean finish. |

| Key Conditions | Oxygen content < 100 ppm, humidity < -40°C, and high purity required. |

| Common Sources | Sourced from liquid nitrogen storage tanks for consistent supply. |

| Other Applications | Used in annealing, sintering, and nitride treatment due to inert properties. |

| Professional Analysis | Experts analyze project needs to recommend optimal brazing environments. |

Need expert advice on using nitrogen for brazing? Contact us today to optimize your heat treatment process!

Visual Guide

Related Products

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Controlled Nitrogen Inert Hydrogen Atmosphere Furnace

- Vertical Laboratory Tube Furnace

People Also Ask

- Why nitrogen is used in annealing furnace? To prevent oxidation and decarburization for superior metal quality

- What is the purpose of inert atmosphere? A Guide to Protecting Your Materials and Processes

- What is nitrogen atmosphere for annealing? Achieve Oxidation-Free Heat Treatment

- Why nitrogen is used in furnace? A Cost-Effective Shield for High-Temperature Processes

- Can nitrogen gas be heated? Leverage Inert Heat for Precision and Safety