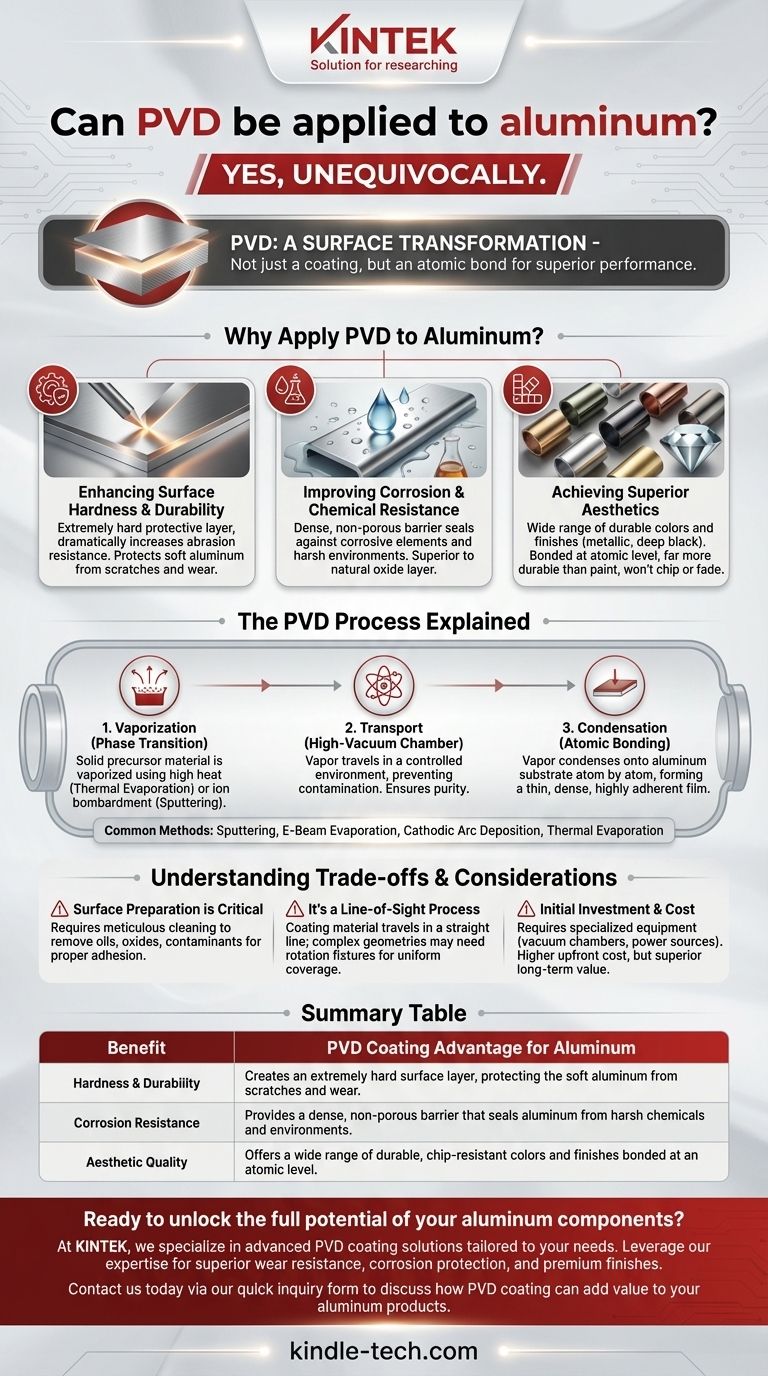

Yes, unequivocally. Physical Vapor Deposition (PVD) is not only compatible with aluminum but is a widely used industrial process to enhance its properties. PVD allows a lightweight and cost-effective material like aluminum to gain superior surface characteristics, including enhanced durability, corrosion resistance, and a premium aesthetic finish.

The core takeaway is that PVD is not simply a coating on aluminum; it's a surface transformation. The process allows you to imbue aluminum with the high-performance characteristics of another material, overcoming aluminum's inherent limitations without sacrificing its low weight.

Why Apply PVD to Aluminum?

Applying a PVD coating to an aluminum substrate is a strategic decision to upgrade the material's performance. It allows designers and engineers to use aluminum in applications where it would otherwise fail.

Enhancing Surface Hardness and Durability

Aluminum is a relatively soft metal, making it prone to scratches and wear. PVD coatings are extremely hard, creating a protective layer that dramatically increases the abrasion resistance of the final product.

Improving Corrosion and Chemical Resistance

While aluminum naturally forms a protective oxide layer, it is still vulnerable to certain chemicals and environmental conditions. A PVD coating provides a dense, non-porous barrier, effectively sealing the aluminum from corrosive elements.

Achieving Superior Aesthetics

PVD can deposit a wide range of materials, offering a variety of colors and finishes—from metallic sheens to deep blacks. These finishes are far more durable than paint or other traditional coloring methods, as the coating is bonded at an atomic level.

The PVD Process Explained

At its core, PVD describes a family of processes that occur within a high-vacuum chamber. This controlled environment is critical for the purity and quality of the final coating.

The Core Principle: Phase Transition

The process involves three fundamental steps. First, a solid precursor material (the coating) is vaporized using a physical method, such as high heat (Thermal Evaporation) or ion bombardment (Sputtering).

Second, this vapor travels through the vacuum chamber. The vacuum ensures the vaporized atoms do not collide with air or other contaminants on their way to the target.

Finally, the vapor condenses onto the aluminum substrate, forming a thin, dense, and highly-adherent film. This happens atom by atom, creating a powerful bond.

Common Deposition Methods

While the principle is the same, several methods exist to vaporize the source material. Common techniques include Sputtering, Electron Beam (E-Beam) Evaporation, Cathodic Arc Deposition, and Thermal Evaporation. The chosen method depends on the coating material and desired film properties.

Understanding the Trade-offs and Considerations

While powerful, PVD is a technical process with specific requirements that must be understood to ensure success.

Surface Preparation is Critical

The quality of a PVD coating is entirely dependent on the cleanliness of the aluminum substrate. The surface must be meticulously cleaned to remove any oils, oxides, or contaminants, as these will prevent proper adhesion.

It's a Line-of-Sight Process

In most PVD methods, the coating material travels in a straight line from the source to the substrate. This means that complex geometries with deep recesses or hidden surfaces can be challenging to coat uniformly without sophisticated part rotation fixtures.

Initial Investment and Cost

PVD requires specialized equipment, including vacuum chambers and high-power energy sources. This makes it a more complex and often more costly process upfront compared to traditional methods like painting or anodizing, though it often provides superior long-term value.

How to Apply This to Your Project

Your decision to use PVD should be driven by the specific performance goal you need to achieve for your aluminum part.

- If your primary focus is aesthetics: PVD provides a premium, highly durable finish in various colors that will not chip, fade, or peel like paint.

- If your primary focus is durability: PVD is the ideal choice for adding a hard, wear-resistant surface to protect aluminum from scratches and abrasion in high-contact applications.

- If your primary focus is corrosion resistance: PVD creates an inert barrier that is essential for protecting aluminum components used in harsh chemical or environmental conditions.

Ultimately, applying PVD to aluminum allows you to engineer a final product that leverages the best of both materials—the lightweight, workable nature of the substrate and the high-performance properties of the coating.

Summary Table:

| Benefit | PVD Coating Advantage for Aluminum |

|---|---|

| Hardness & Durability | Creates an extremely hard surface layer, protecting the soft aluminum from scratches and wear. |

| Corrosion Resistance | Provides a dense, non-porous barrier that seals aluminum from harsh chemicals and environments. |

| Aesthetic Quality | Offers a wide range of durable, chip-resistant colors and finishes bonded at an atomic level. |

Ready to unlock the full potential of your aluminum components?

At KINTEK, we specialize in advanced PVD coating solutions tailored to your specific needs. Whether your project demands superior wear resistance, enhanced corrosion protection, or a premium, long-lasting finish, our expertise in lab equipment and consumables ensures a high-quality result.

Contact us today via our quick inquiry form to discuss how PVD coating can add value to your aluminum products and elevate your project's performance.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition