In short, yes. Certain types of vacuum tubes can be professionally rebuilt and reconditioned. This is a highly specialized service primarily for large, expensive, and often irreplaceable tubes used in high-power applications like broadcast transmitters and industrial machinery.

The ability to rebuild a vacuum tube is not a question of technical possibility, but of economic viability. The process is reserved for high-value industrial tubes where replacement is either impossible or prohibitively expensive, making it an irrelevant option for common consumer electronics.

What "Rebuilding" a Vacuum Tube Involves

Rebuilding a vacuum tube is a meticulous and complex industrial process, far removed from a simple repair. It involves completely reconstructing the tube to meet or exceed its original factory specifications.

The Core Process

The process requires a specialized facility. Technicians carefully disassemble the tube, which may involve cutting open the glass or ceramic envelope.

All internal components—such as the anode, grids, and filament structures—are chemically cleaned and inspected for wear and tear.

Component Replacement and Reassembly

The most critical step is often the replacement of worn-out components. The cathode or filament, which is the electron-emitting element and has a finite lifespan, is almost always replaced.

Once the internal structure is restored, it is sealed in a new envelope. The tube is then connected to a high-power vacuum pump system and baked at high temperatures to force out any trapped gasses from the metal components.

Achieving a Hard Vacuum

The final, and most crucial, stage is creating an extremely hard vacuum inside the tube. Any residual gas molecules would interfere with the flow of electrons, causing poor performance and rapid failure. After evacuation, the tube is sealed and rigorously tested.

Why Rebuild Instead of Replace?

The decision to rebuild a tube is almost always driven by pragmatism. For certain applications, it is the only logical path forward.

Economic Viability

A new, high-power transmitting triode or tetrode can cost tens of thousands of dollars. A professional rebuild can restore the tube to as-new condition for a fraction of that cost, making it a sound financial decision.

Scarcity and Availability

Many specialized vacuum tubes are no longer in production. For legacy industrial, medical, or broadcast equipment, finding a new replacement may be impossible. In these cases, rebuilding is the only option to keep critical systems operational.

Original Performance Specifications

A rebuilt tube is restored to its original design parameters. This can be superior to using a modern "equivalent" that may have slightly different electrical characteristics, ensuring the equipment performs exactly as it was originally designed to.

Understanding the Limitations

While rebuilding is a powerful solution, it's essential to understand its specific application and scope. This is not a universal service for all types of tubes.

Not for Consumer Tubes

This process is not applicable to the small, common glass tubes found in guitar amplifiers or home audio equipment (e.g., 12AX7, EL34). The cost of rebuilding would vastly exceed the price of a brand-new replacement tube, which is readily available.

The Need for Specialists

Rebuilding vacuum tubes is not a DIY project. It requires a clean-room environment, expensive vacuum pumps, specialized welding equipment, and deep institutional knowledge. As the reference material notes, this is the domain of experienced technicians in state-of-the-art facilities.

Quality is Paramount

The reliability of a rebuilt tube is entirely dependent on the skill of the rebuilder and the quality of their process. Choosing a reputable firm with a long track record is critical to ensuring the final product is safe and performs to specification.

Making the Right Choice for Your Goal

Your decision to seek a rebuild or a replacement depends entirely on the type of equipment you are maintaining.

- If your primary focus is high-power equipment (broadcast, industrial, medical): Rebuilding is often your most cost-effective and practical solution for expensive, hard-to-find tubes like large triodes and tetrodes.

- If your primary focus is consumer audio or hobbyist electronics: Rebuilding is not a viable option. Your best course is to find New Old Stock (NOS) or modern production replacement tubes.

Understanding the distinction between industrial rebuilding and consumer replacement empowers you to make the most efficient decision for your equipment.

Summary Table:

| Aspect | Rebuildable Tubes | Non-Rebuildable Tubes |

|---|---|---|

| Typical Use | Broadcast transmitters, industrial machinery | Consumer audio, guitar amps |

| Cost Factor | High-value (often $10,000+) | Low-cost, readily available |

| Availability | Often out of production, scarce | New Old Stock (NOS) or modern production |

| Primary Benefit | Cost-effective restoration, maintains original specs | Simple, direct replacement |

Keep your critical high-power systems running at peak performance.

If you rely on expensive or hard-to-find industrial vacuum tubes for your broadcast, medical, or industrial equipment, a professional rebuild from KINTEK can restore your tube to its original specifications for a fraction of the cost of a new one.

KINTEK specializes in the precise lab equipment and technical expertise required for this meticulous process. Our state-of-the-art facilities ensure your rebuilt tube meets the highest standards of performance and reliability.

Contact KINTEK today for a consultation on your specific vacuum tube needs and discover how we can help you maintain your vital equipment efficiently.

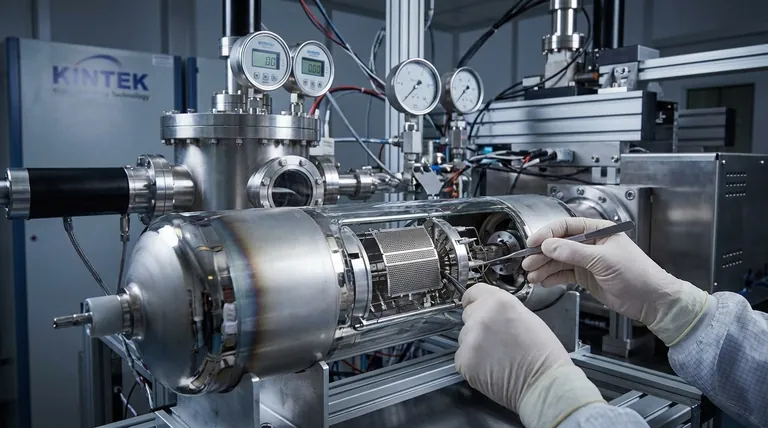

Visual Guide

Related Products

- KF/ISO/CF Ultra-High Vacuum Stainless Steel Flange Pipe/Straight Pipe/Tee/Cross

- Laboratory High Pressure Vacuum Tube Furnace

- 304 316 Stainless Steel Vacuum Ball Valve Stop Valve for High Vacuum Systems

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What does retort mean in furnace? Unlock Precise Atmosphere Control for Metallurgical Processes

- What equipment is used in annealing? Selecting the Right Furnace for Your Process

- What is the technical value of using a high-vacuum heat treatment furnace for 800 °C annealing? Maximize Bond Strength

- What is the difference between ion and gas nitriding? Choose the Best Surface Hardening Method

- What is the primary role of a high-temperature vacuum furnace in chromium powder granulation? Key Sintering Insights

- What temperature do you anneal steel at? Achieve Perfect Softness and Ductility

- What are the benefits of heat treatment? Enhance Material Strength, Durability, and Performance

- Can I vacuum the inside of my furnace? A Guide to Safe DIY Cleaning vs. Professional Service