Yes, you absolutely can. An induction furnace is a highly effective tool for melting aluminum and its alloys. The process relies on creating a powerful magnetic field to generate heat directly within the metal itself, allowing for rapid, clean, and controlled melting.

While an induction furnace is one of the best methods for melting aluminum, success depends entirely on using the right type of furnace. Aluminum's high electrical conductivity means a standard iron-melting furnace will be inefficient; a unit operating at a higher frequency is required for optimal performance.

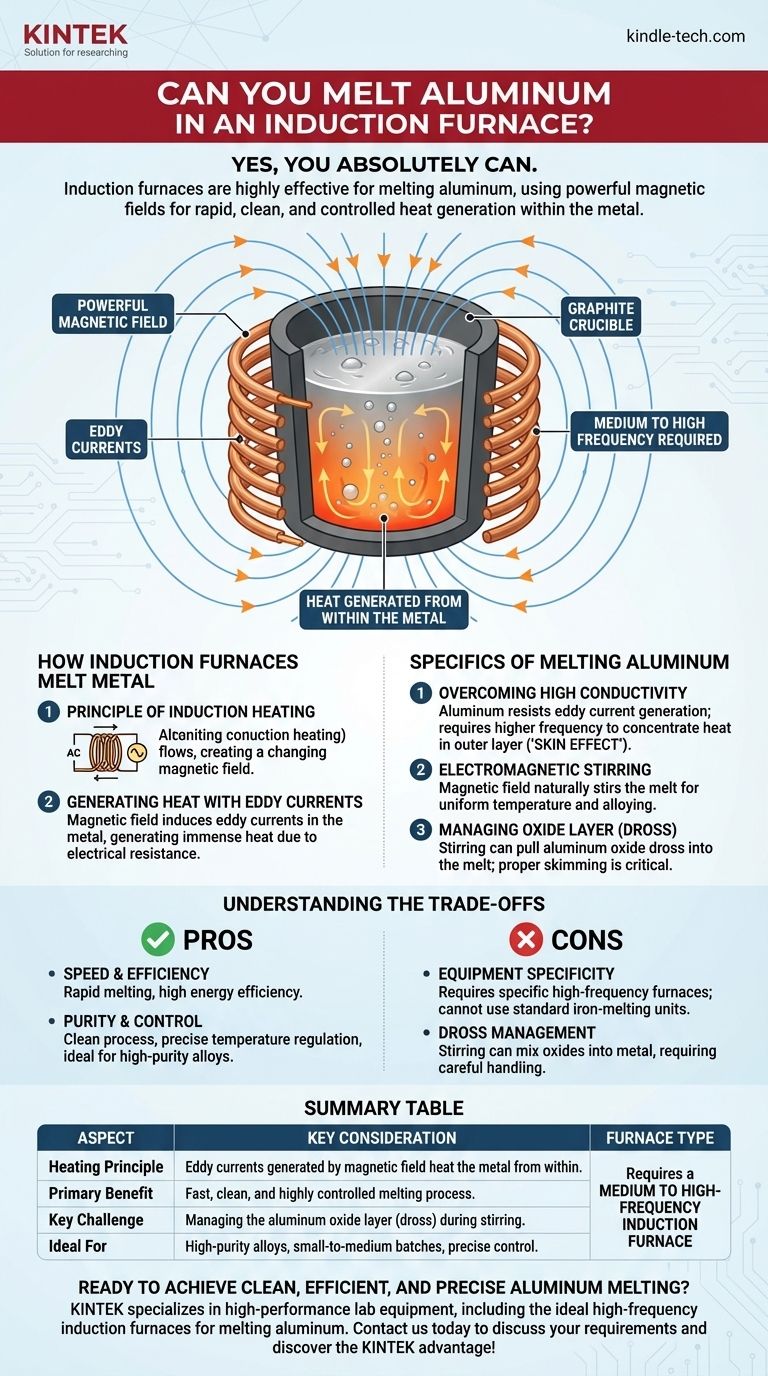

How Induction Furnaces Melt Metal

The Principle of Induction Heating

An induction furnace uses a coil of conductive material, typically copper, through which a powerful alternating electrical current is passed. This current generates a rapidly changing magnetic field around and within the crucible holding the metal charge.

Generating Heat with Eddy Currents

This magnetic field induces powerful electrical currents within the metal itself, known as eddy currents. Due to the metal's natural electrical resistance, these eddy currents generate immense heat, causing the metal to melt from the inside out.

The Specifics of Melting Aluminum

Overcoming High Conductivity

Aluminum is an excellent electrical conductor, much more so than steel or iron. This property means it resists the generation of eddy currents. To overcome this, induction furnaces for aluminum must operate at a medium to high frequency.

A higher frequency concentrates the heating effect in a thinner outer layer of the metal (a phenomenon known as the skin effect), transferring energy more efficiently and enabling a rapid melt. A low-frequency furnace designed for iron would struggle to heat aluminum effectively.

The Benefit of Electromagnetic Stirring

The magnetic field that heats the metal also creates a natural stirring action within the molten bath. This is highly beneficial for mixing in alloys and ensuring a uniform temperature and chemical composition throughout the melt.

Managing the Oxide Layer (Dross)

Aluminum rapidly forms a tough, thin layer of aluminum oxide on its surface when exposed to air. The stirring action of an induction furnace can pull this oxide, or dross, into the melt. Proper operational procedure, including skimming the surface before pouring, is critical to prevent these inclusions and ensure a high-quality casting.

Understanding the Trade-offs

Pro: Speed and Efficiency

As referenced, a properly sized induction furnace can melt a batch of aluminum very quickly, sometimes in minutes. Because the heat is generated within the metal, very little energy is wasted heating the furnace chamber, making the process highly energy-efficient compared to traditional fuel-fired methods.

Pro: Purity and Control

Induction melting is an exceptionally clean process. There are no products of combustion to contaminate the metal. This, combined with precise digital temperature control, makes it the ideal choice for producing high-purity, specification-critical aluminum alloys.

Con: Equipment Specificity

The primary drawback is the need for the right equipment. You cannot efficiently melt aluminum in a low-frequency furnace designed for large-scale iron melting. The initial capital investment for a high-frequency furnace can be significant.

Con: Dross Management is Critical

While the stirring is a benefit for alloying, it makes dross management a constant concern. If not managed properly, the stirring can lead to a lower-quality final product by mixing oxides into the metal.

Making the Right Choice for Your Application

Choosing the right melting method depends entirely on your specific goals.

- If your primary focus is high-purity alloys and precise control: An induction furnace is the superior choice due to its cleanliness, speed, and unmatched temperature regulation.

- If your primary focus is melting small-to-medium batches with rapid turnaround: The speed of induction melting is a significant operational advantage.

- If you are melting various metals in one facility: A modern, variable-frequency induction furnace offers the flexibility to efficiently melt everything from iron to copper to aluminum.

By matching the furnace's frequency to aluminum's unique properties, you can leverage induction technology for exceptionally clean and controlled melts.

Summary Table:

| Aspect | Key Consideration for Melting Aluminum |

|---|---|

| Furnace Type | Requires a medium to high-frequency induction furnace |

| Heating Principle | Eddy currents generated by a magnetic field heat the metal from within |

| Primary Benefit | Fast, clean, and highly controlled melting process |

| Key Challenge | Managing the aluminum oxide layer (dross) during the stirring process |

| Ideal For | High-purity alloys, small-to-medium batches, and precise temperature control |

Ready to achieve clean, efficient, and precise aluminum melting?

KINTEK specializes in high-performance lab equipment, including the ideal induction furnaces for melting aluminum and its alloys. Our experts will help you select the right high-frequency unit to ensure rapid melt times, superior purity, and exact temperature control for your specific laboratory needs.

Contact us today to discuss your aluminum melting requirements and discover the KINTEK advantage!

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the principle of vacuum induction melting? Achieve Ultra-High Purity Metals

- What principle is used to generate heat in a vacuum induction melting furnace? Achieve Clean, Efficient Metal Melting

- What is the vacuum induction method? Master High-Purity Metal Melting for Advanced Alloys

- What types of metals are typically processed in a vacuum induction melting furnace? High-Purity Alloys for Critical Applications

- What is VIM in metallurgy? A Guide to Vacuum Induction Melting for High-Performance Alloys