Yes, activated carbon can be restored, but not in the way most people think. The process, known as thermal reactivation, is a highly specialized industrial procedure that uses extreme heat to burn off trapped contaminants, making the carbon reusable. It is not a process that can be done at home.

While it is technically possible to restore activated carbon, the method requires industrial-grade equipment and temperatures exceeding 800°C (1500°F). For nearly all home, aquarium, or small-scale commercial uses, replacement is the only practical and safe option.

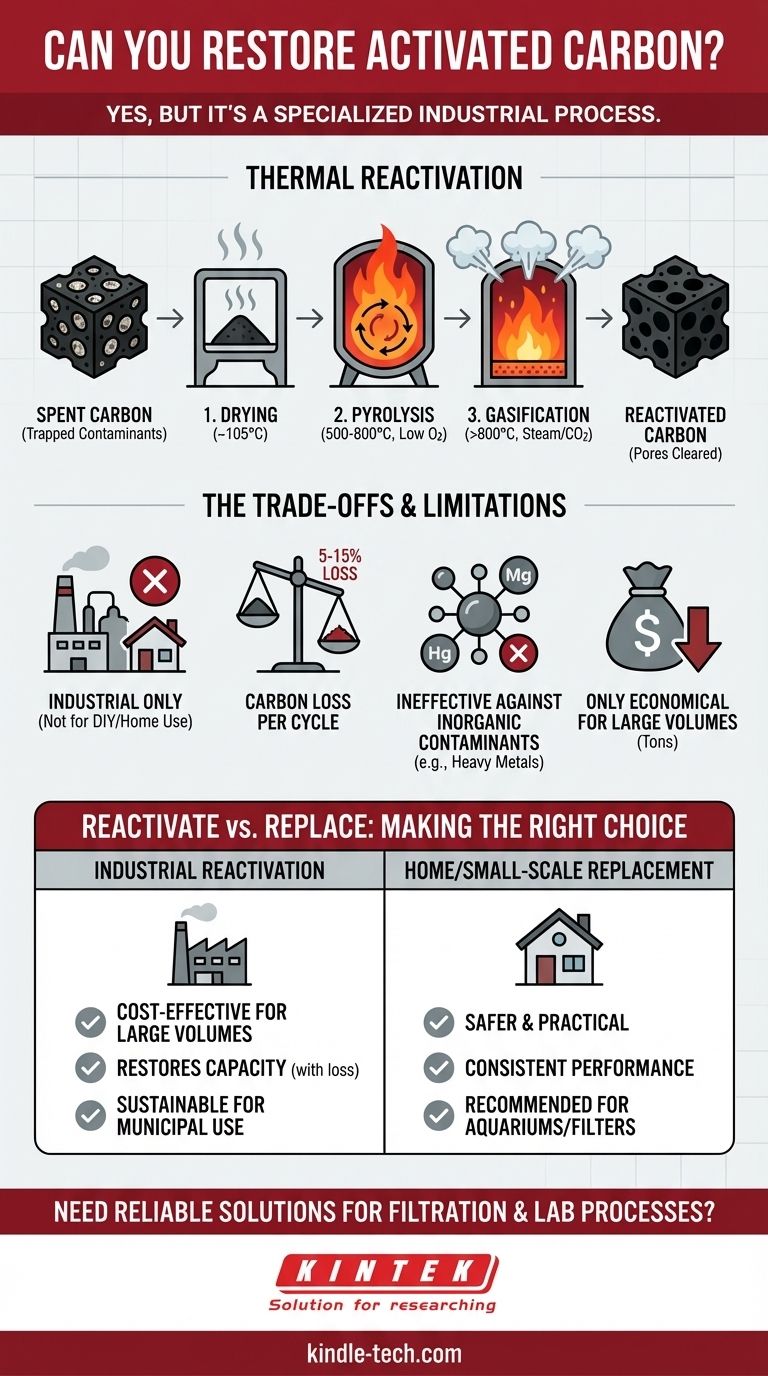

How Activated Carbon is Restored: Thermal Reactivation

The ability of activated carbon to work depends entirely on its vast internal surface area and porous structure, where it traps contaminants via a process called adsorption. Reactivation is designed to clear these pores, effectively resetting the carbon for another cycle.

The Core Principle: Incinerating Contaminants

At its heart, reactivation involves heating the spent carbon in a highly controlled, multi-stage process. The intense heat is designed to break down and vaporize the organic contaminants that have been adsorbed onto the carbon's surface.

A Multi-Stage Industrial Process

This isn't a simple baking process. It takes place in large, rotating kilns or vertical furnaces and involves several precise steps:

- Drying: The carbon is first heated to around 105°C (220°F) to remove all water.

- Pyrolysis (Desorption): The temperature is then raised to 500-800°C (930-1500°F) in a low-oxygen environment. This "bakes off" the volatile organic compounds without burning the carbon itself.

- Gasification: Finally, the temperature is increased above 800°C (1500°F) as steam or carbon dioxide is injected. This final, crucial step burns away any remaining char and re-exposes the carbon's original porous structure, "reactivating" it.

Why This Process Works

The high-temperature gasification step is what truly restores the carbon. It selectively removes the residual contaminant molecules and char, clearing the microscopic pores and restoring the immense surface area needed for effective adsorption.

Understanding the Trade-offs and Limitations

While effective, thermal reactivation is a process of diminishing returns and is only suitable for specific scenarios. Understanding its limitations is key to making a sound decision.

It's an Industrial Process, Not a DIY Task

The primary limitation is the equipment. The process requires precise temperature control, a controlled atmosphere to prevent the carbon from simply turning to ash, and safety measures to handle the off-gassing of vaporized contaminants. This cannot be replicated in a home oven or with a blowtorch.

Inevitable Carbon Loss

Each reactivation cycle is abrasive and burns off a small amount of the carbon itself. Typically, there is a 5-15% loss of carbon material with every cycle. This means the carbon cannot be restored indefinitely.

Contaminant-Specific Challenges

Reactivation works best for carbon that has adsorbed organic compounds. It is ineffective against inorganic contaminants like heavy metals, which do not vaporize and will remain in the carbon's structure, permanently reducing its effectiveness.

Economic Viability

The significant energy and capital costs of running a reactivation facility mean it is only economical for very large quantities of activated carbon, typically measured in tons. For smaller amounts, the cost of reactivation would far exceed the price of new carbon.

Making the Right Choice: Reactivate or Replace?

The decision is not about which method is better, but which is appropriate for your specific application and scale.

- For large-scale industrial or municipal operations: Reactivation is often the most cost-effective and sustainable solution for managing large volumes of spent carbon.

- For home use (e.g., aquariums, water filters, air purifiers): Always opt for replacement. Attempting to restore carbon at home is impractical, ineffective, and potentially hazardous.

- For small-to-medium business use: Replacement remains the standard procedure unless you are generating multiple tons of spent carbon on a consistent basis.

Ultimately, knowing the difference between industrial reactivation and practical replacement is key to using activated carbon effectively and safely.

Summary Table:

| Aspect | Industrial Reactivation | Home/DIY Attempts |

|---|---|---|

| Process | Multi-stage thermal treatment (>800°C) | Baking, boiling, or torching |

| Effectiveness | Restores adsorption capacity | Ineffective; can damage carbon |

| Safety | Controlled environment, handles off-gassing | Hazardous; risk of fire and toxic fumes |

| Cost-Effectiveness | Economical for large volumes (tons) | Not economical; cost exceeds new carbon |

| Best For | Large-scale industrial/municipal use | Not recommended; replacement is advised |

Need reliable activated carbon or lab equipment for your filtration processes?

At KINTEK, we specialize in providing high-quality laboratory equipment and consumables to ensure your operations run efficiently and safely. Whether you're managing an industrial-scale reactivation facility or need consistent, high-performance activated carbon for your applications, our expertise and products are tailored to meet your needs.

Let us help you optimize your process. Contact our experts today for a personalized solution!

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

People Also Ask

- What is a carbon regeneration kiln? Reuse Spent Carbon to Cut Costs & Waste

- What is a calciner kiln? The High-Temperature Reactor for Material Transformation

- What are the main parts of a rotary kiln? A Guide to Its Core Components and System

- Can reactors be used for the pyrolysis of plastic waste? The Core Technology Explained

- What are the requirements for activated carbon? Matching Properties to Your Application for Success

- How long does it take to produce biochar? From Seconds to Hours, Based on Your Goal

- How does carbon regeneration work? Restore Your Activated Carbon's Performance

- What is the regeneration of carbon? Restore Your Spent Activated Carbon for Reuse