Yes, you can absolutely use a hydraulic press for blacksmithing. In fact, for certain tasks, it is vastly superior to a traditional hammer or even a power hammer. It's not a universal replacement for striking tools, but rather a powerful and precise complement that excels at moving large amounts of metal with immense, controlled force.

The core difference is simple: a hammer works by impact, while a press works by pressure. Understanding this distinction is the key to knowing when a press is the right tool for the job, offering silent, deep-penetrating force where a hammer offers speed and surface refinement.

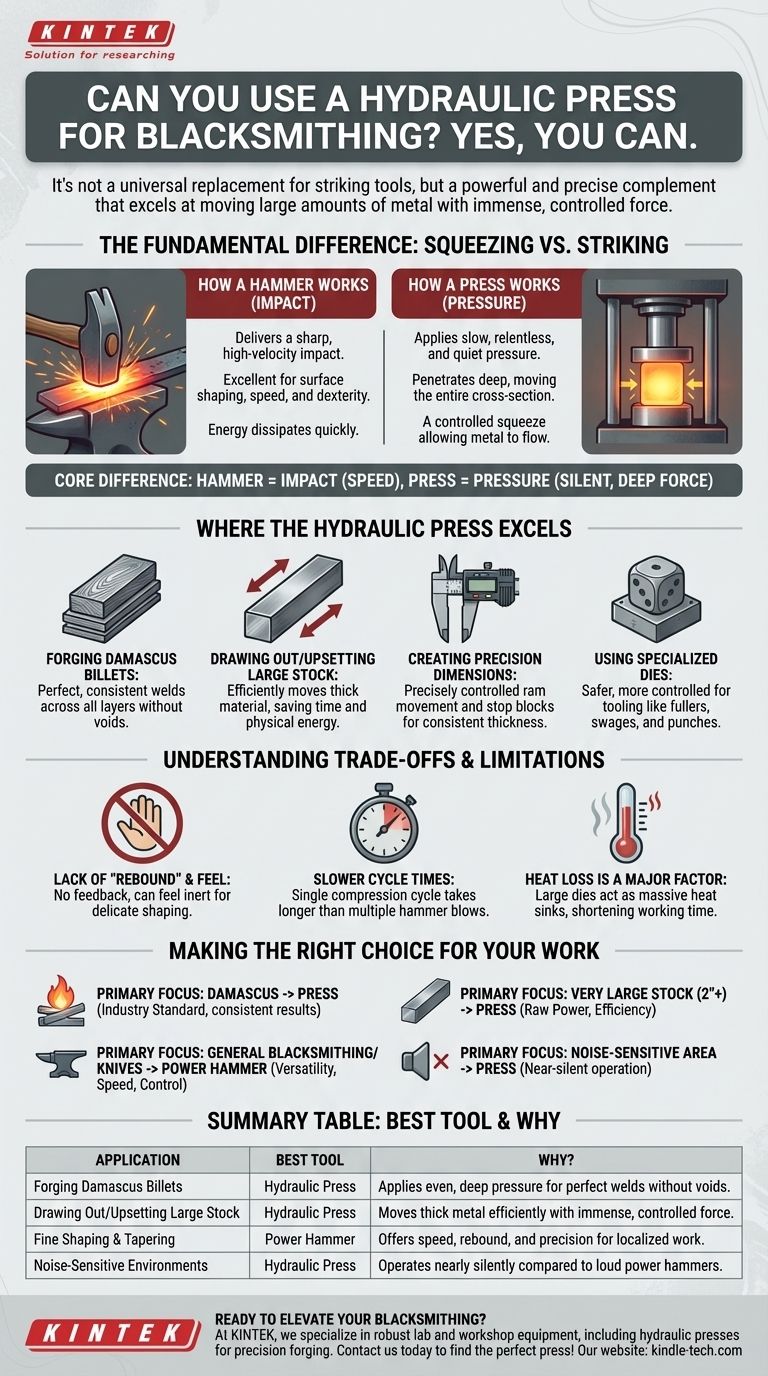

The Fundamental Difference: Squeezing vs. Striking

To understand the role of a press, you must first appreciate that it applies force in a fundamentally different way than a hammer.

How a Hammer Works (Impact)

A hammer, whether swung by hand or driven by a machine, delivers a sharp, high-velocity impact. This percussive force is excellent for shaping the surface of the metal and for tasks that require speed and dexterity.

The energy from a hammer blow dissipates quickly, primarily affecting the metal closest to the point of impact.

How a Press Works (Pressure)

A hydraulic press applies slow, relentless, and quiet pressure. This force penetrates deep into the core of the workpiece, moving the entire cross-section of the metal at once.

Instead of a rapid strike, it's a controlled squeeze that gives the metal time to flow and re-form.

The Impact on Metal Structure

This "squeezing" action is exceptionally effective for forge welding, such as in the creation of damascus steel. It sets welds perfectly across entire surfaces without the bouncing or potential shearing that can occur with off-center hammer blows.

Where the Hydraulic Press Excels

A press is not a general-purpose tool; it's a specialist. It shines in applications where raw power and control are paramount.

Forging Damascus Billets

This is the quintessential task for a forging press. The slow, even pressure ensures all layers of a billet achieve a perfect weld simultaneously, resulting in clean, consistent patterns without voids.

Drawing Out and Upsetting Large Stock

Moving a 2-inch square bar with a hammer is a slow, exhausting process. A press can squeeze that same bar down with staggering efficiency, saving both time and physical energy. The same is true for upsetting (making metal shorter and thicker).

Creating Precision Dimensions

Because the movement of the ram can be precisely controlled, a press is ideal for creating stock of a consistent thickness. Using "stop blocks" allows you to press a workpiece down to an exact dimension every single time.

Using Specialized Dies

A press is significantly safer and more controlled for using tooling like fullers, swages, and punches. The slow speed eliminates the risk of a die flying out from a misplaced hammer blow and allows for precise, repeatable shaping.

Understanding the Trade-offs and Limitations

A press is a powerful tool, but it is not the solution for every forging problem. Its greatest strengths also create its primary weaknesses.

Lack of "Rebound" and Feel

Experienced smiths use the rebound of the hammer to work quickly and "feel" the metal moving. A press offers no such feedback, making it feel clumsy and inert for delicate or intuitive shaping.

Slower Cycle Times

A power hammer can deliver dozens of blows in the time it takes a press to complete a single compression and retraction cycle. For tasks requiring many rapid adjustments, the hammer is far faster.

Heat Loss is a Major Factor

The large, flat dies of a press act as massive heat sinks. They pull heat from the workpiece much faster than the small face of a hammer. This means you have a shorter working time before you must return the metal to the forge.

Not Ideal for Fine Shaping or Isolation

Trying to draw a fine taper on a blade or isolate a small section of a piece is difficult with a press. The broad force application is a disadvantage when you need to work on a specific, localized area. A hammer is the far superior tool for this kind of work.

Making the Right Choice for Your Work

Ultimately, the decision to use a press depends entirely on the type of work you intend to do. It is not a question of which tool is "better," but which one is right for the task.

- If your primary focus is making damascus or pattern-welded steel: A hydraulic press is the industry standard and will provide the most consistent and high-quality results.

- If your primary focus is general blacksmithing, knives, or sculptural work: A power hammer offers greater versatility, speed, and the control needed for complex shaping and tapering.

- If your primary focus is working with very large stock (2"+): A press provides the raw power to move thick material with an efficiency that a hammer simply cannot match.

- If your primary focus is operating in a noise-sensitive area: The near-silent operation of a press is a decisive advantage over the deafening report of a power hammer.

Choosing your tools is about matching the application of force to your specific goal.

Summary Table:

| Application | Best Tool | Why? |

|---|---|---|

| Forging Damascus Billets | Hydraulic Press | Applies even, deep pressure for perfect welds without voids. |

| Drawing Out/Upsetting Large Stock | Hydraulic Press | Moves thick metal efficiently with immense, controlled force. |

| Fine Shaping & Tapering | Power Hammer | Offers speed, rebound, and precision for localized work. |

| Noise-Sensitive Environments | Hydraulic Press | Operates nearly silently compared to loud power hammers. |

Ready to elevate your blacksmithing with the right equipment? At KINTEK, we specialize in robust lab and workshop equipment, including hydraulic presses designed for precision forging, damascus steel creation, and efficient metalworking. Whether you're a professional bladesmith or a serious hobbyist, our tools deliver the controlled force and reliability you need. Contact us today to find the perfect press for your workshop and experience the KINTEK difference in quality and performance!

Visual Guide

Related Products

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What products can be made on a hydraulic press? From Metal Parts to Lab Samples

- What are press machines used for? Shaping, Bonding, and Compressing Materials with Precision

- What is the purpose of a laboratory hydraulic press for LATP electrolyte pellets? Achieve Optimal Density & Conductivity

- Why is hydraulic oil bad for the environment? The Hidden Dangers of Petroleum-Based Fluids

- How does a laboratory hydraulic press ensure product quality in NFPC preparation? Achieve Superior Composite Strength

- Why is a laboratory hydraulic press necessary for Ti2AlN ceramics? Ensure Structural Integrity & High Density

- What function does a laboratory hydraulic press serve in photocatalytic pigments? | Enhance Sample Standardization

- What role do hydraulic presses play in graphene transfer? Achieve Precise Bonding and Defect-Free Membranes