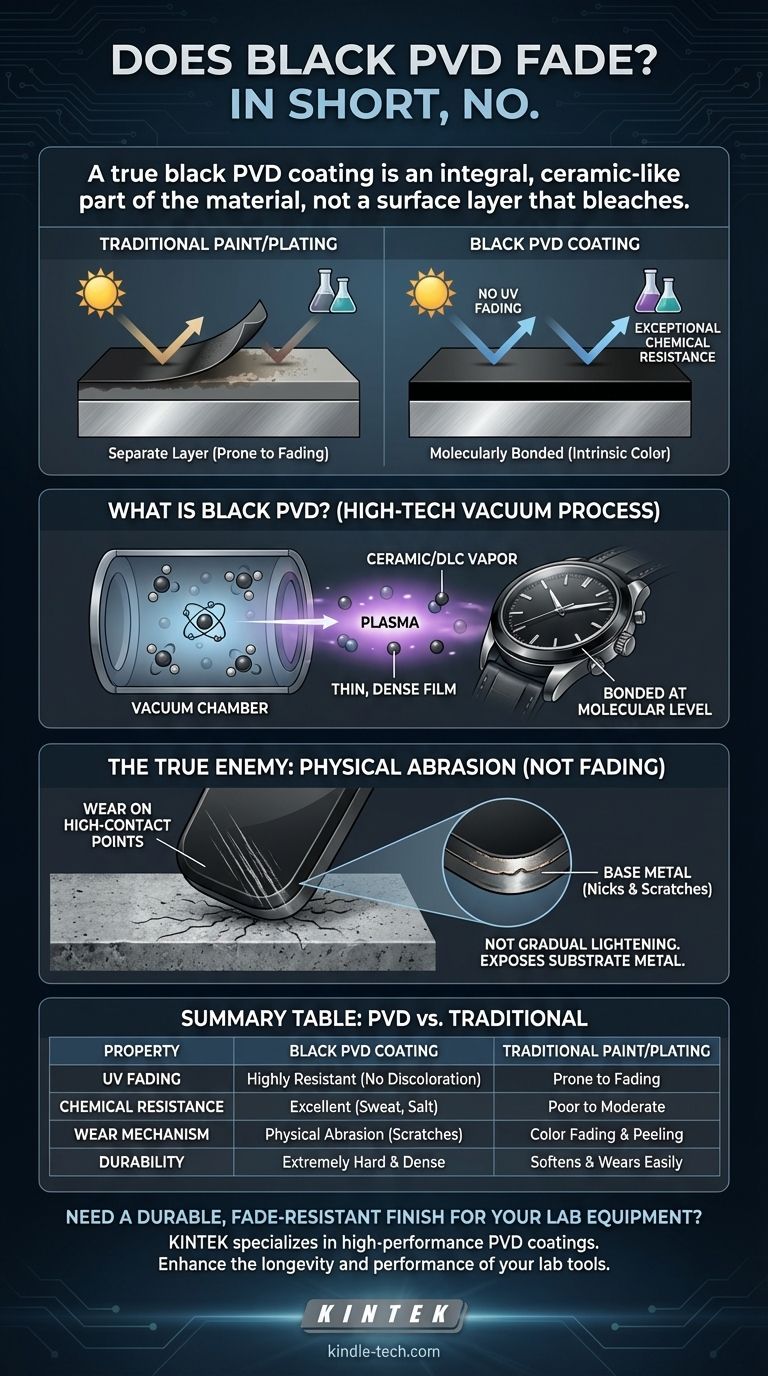

In short, no. A true black PVD coating does not "fade" in the way paint or a dye would. The color is not a separate layer that can be bleached by the sun; it is an integral part of a hard, ceramic-like material bonded to the base metal. However, it is not indestructible and can wear away over time through physical abrasion, revealing the metal underneath.

PVD's exceptional durability means its primary vulnerability is not color fading from UV light or chemicals, but rather long-term physical wear and scratching that can expose the substrate metal on high-contact points.

What Exactly is Black PVD?

To understand why PVD (Physical Vapor Deposition) doesn't fade, you must first understand that it isn't a paint, powder coat, or traditional plating. It is a fundamentally different and far more advanced process.

A High-Tech Vacuum Process

PVD is a process conducted in a high-vacuum chamber where a solid material—often a ceramic like Titanium Nitride or Diamond-Like Carbon (DLC)—is vaporized into a plasma of atoms.

These atoms are then deposited onto the target object (like a watch case or faucet), bonding to it on a molecular level.

A Thin Film, Not a Wet Coating

This process creates an extremely thin yet incredibly hard and dense film over the substrate metal. The black color is an intrinsic property of the deposited material itself, not a pigment that can break down.

Why PVD Excels in Color Stability

The molecular structure of a PVD coating makes it inherently resistant to the environmental factors that cause other finishes to fail.

Immunity to UV Fading

Because the color is part of a stable, ceramic-like atomic structure, it is not susceptible to being broken down by ultraviolet (UV) radiation from the sun. It will not discolor or lose its vibrancy over time.

Exceptional Chemical Resistance

PVD coatings are highly inert. They can easily withstand exposure to sweat, salt water, and common household chemicals that would tarnish or discolor lesser finishes.

Understanding the Real-World Wear and Tear

While PVD is incredibly tough, it is not invincible. The perception of "fading" almost always comes from a misunderstanding of how it wears.

The True Enemy: Abrasion

The primary threat to a PVD coating is physical abrasion. This means scraping it against hard, rough surfaces like concrete, brick, sand, or even other hardened metals.

Over many years, this type of contact will gradually wear the coating away, particularly on sharp edges and high-contact points like a watch clasp or bracelet links.

How Wear Actually Appears

You will not see a gradual lightening of the black color. Instead, you will eventually see small nicks, scratches, or worn patches where the thin PVD layer has been completely removed, revealing the silver-colored stainless steel or titanium base metal underneath.

Durability Is Not Invincibility

Think of PVD as armor for your product. It provides a massive upgrade in scratch resistance compared to bare steel, but a hard enough impact or a significant scrape will eventually get through any armor.

The Proof Is in Its Removal

The extreme durability of PVD is underscored by the difficulty of removing it. Stripping a PVD coating requires specialized industrial processes, a testament to how strongly it is bonded and how resistant it is to everyday wear.

Making the Right Choice for Your Goal

Understanding how PVD performs allows you to set realistic expectations for your product's long-term appearance.

- If your primary focus is daily wear and color stability: PVD is an outstanding choice. It will not fade from sun or sweat and offers superior scratch resistance for everyday situations.

- If your primary focus is a pristine, flawless look forever: Recognize that no finish is permanent. A black PVD-coated item that is used heavily will eventually show signs of its history through scratches and wear on the edges.

- If you are choosing between PVD and cheaper "blackened" metals: PVD offers vastly superior longevity and durability, making it a far better investment for any item you intend to keep for years.

By understanding that PVD's challenge is physical wear rather than color fading, you can better predict its long-term performance and value.

Summary Table:

| Property | Black PVD Coating | Traditional Paint/Plating |

|---|---|---|

| UV Fading | Highly Resistant | Prone to Fading |

| Chemical Resistance | Excellent (sweat, salt water) | Poor to Moderate |

| Wear Mechanism | Physical Abrasion (scratches) | Color Fading & Peeling |

| Durability | Extremely Hard & Dense | Softens and Wears Easily |

Need a Durable, Fade-Resistant Finish for Your Laboratory Equipment?

KINTEK specializes in high-performance PVD coatings for lab equipment and consumables. Our advanced coating technology ensures your products withstand harsh environments, chemicals, and daily wear without losing their aesthetic appeal. Enhance the longevity and performance of your lab tools – contact our experts today to discuss your specific needs!

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Dental Porcelain Sintering Furnace

- Multi-zone Laboratory Tube Furnace

People Also Ask

- Is diamond coating permanent? The Truth About Its Long-Lasting Durability

- How are tools coated with diamond? Achieve Superior Hardness and Low Friction for Your Tools

- What are the three types of coating? A Guide to Architectural, Industrial, and Special Purpose

- What is the process of CVD diamond coating? Grow a Superior, Chemically-Bonded Diamond Layer

- How long does diamond coating last? Maximize Lifespan with the Right Coating for Your Application