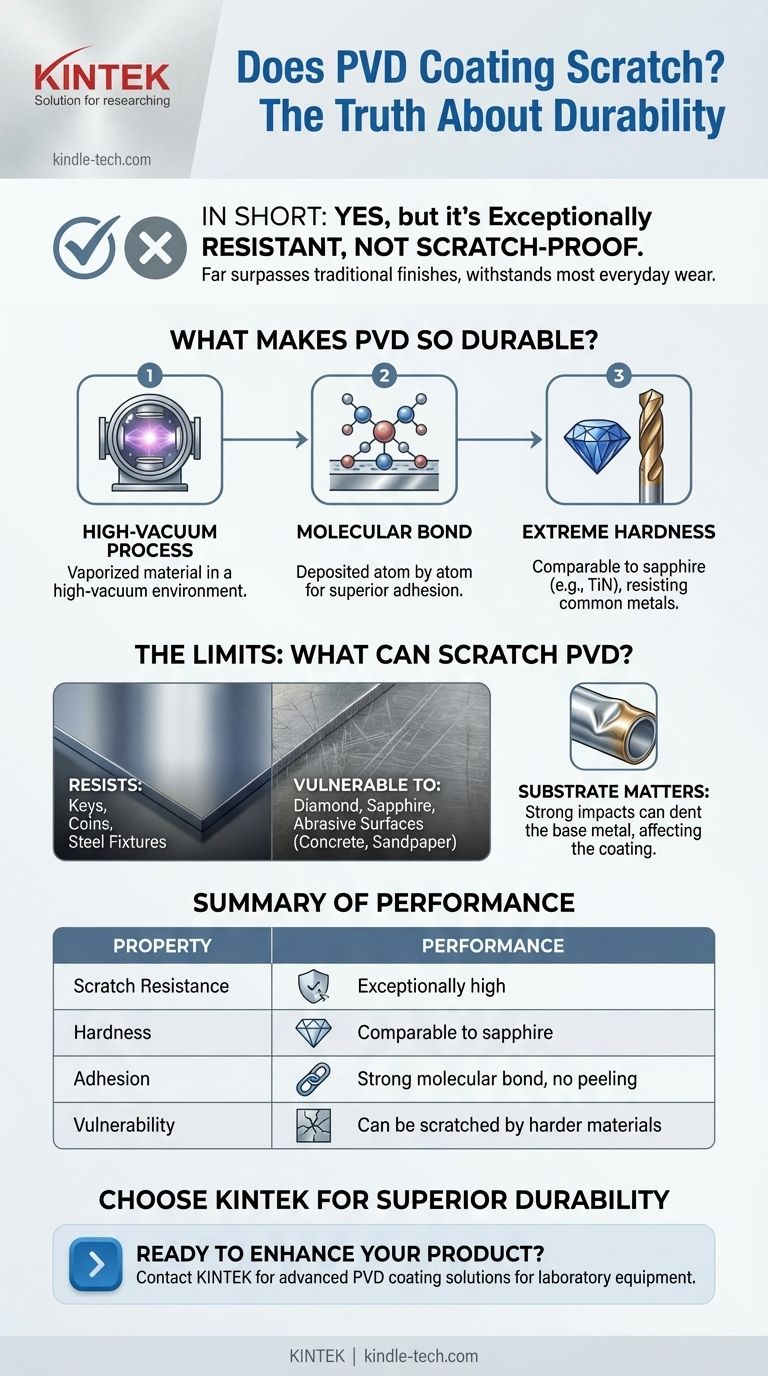

In short, yes, PVD coatings can be scratched. While PVD (Physical Vapor Deposition) is not scratch-proof, it is exceptionally scratch-resistant. Its durability and hardness far surpass traditional coating methods, but it is still vulnerable to damage from materials that are harder than it or from significant abrasive force.

The critical distinction is that PVD is not invincible, but rather highly resilient. Its value comes from its ability to withstand the vast majority of everyday wear and tear that would easily damage conventional finishes like paint or electroplating.

What Makes PVD So Durable?

To understand why PVD coatings are so tough, you have to look at the process itself and the materials used. It's fundamentally different from a simple layer of paint.

The "Physical Vapor Deposition" Process

PVD is a process conducted in a high-vacuum environment. A solid, high-purity coating material (like titanium or chromium) is vaporized into a plasma of atoms and ions. This vapor is then deposited onto the surface of the object, creating a thin film that is bonded at a molecular level.

Extreme Hardness

This process creates a surface that is incredibly hard. For example, a Titanium Nitride (TiN) PVD coating has a hardness comparable to sapphire. This means it can resist being scratched by most common metals you would encounter, such as keys, steel fixtures, or door handles.

Superior Adhesion

Because the coating is bonded atom by atom, it adheres to the base material with exceptional strength. This molecular bond makes PVD coatings highly resistant to the chipping, flaking, and peeling that are common failure points for traditional finishes.

Understanding the Trade-offs: The Limits of PVD

Building trust requires understanding not just the strengths, but also the limitations. No coating is indestructible, and PVD is no exception.

Scratch-Resistant vs. Scratch-Proof

A PVD finish will easily shrug off accidental scuffs from daily life. However, it is not proof against any and all damage. Materials with a higher hardness value can and will scratch it.

What Can Scratch PVD?

A PVD coating can be damaged by materials like diamond, sapphire, or extremely abrasive surfaces like rough concrete or coarse sandpaper. A concentrated, high-pressure scrape against a sharp, hard edge could also compromise the finish.

The Substrate Still Matters

The durability of the final product also depends on the material underneath the PVD coating. A strong impact can dent the softer base metal (like stainless steel). While the PVD coating itself might not have been scratched through, the underlying dent will cause the coating to deform, resulting in visible damage.

Making the Right Choice for Your Application

Your decision to choose a PVD-coated product should be based on a realistic expectation of its performance in your specific environment.

- If your primary focus is everyday wear (watches, jewelry, faucets): PVD offers outstanding protection against the common scuffs and minor abrasions that quickly degrade traditional finishes.

- If your primary focus is high-impact or extreme use (tools, industrial parts): While PVD is a top-tier choice for surface hardness and wear resistance, understand that direct, forceful impacts can still cause damage to the underlying material.

Ultimately, choosing PVD means investing in one of the most resilient and long-lasting finishes available, providing superior durability for most real-world scenarios.

Summary Table:

| Property | PVD Coating Performance |

|---|---|

| Scratch Resistance | Exceptionally high, far superior to traditional finishes |

| Hardness | Comparable to sapphire (e.g., TiN coatings) |

| Adhesion | Strong molecular bond, resists chipping and peeling |

| Vulnerability | Can be scratched by harder materials (diamond, sapphire, abrasive surfaces) |

Ready to enhance your product's durability with a superior finish? KINTEK specializes in advanced PVD coating solutions for laboratory equipment and consumables. Our coatings provide exceptional scratch and wear resistance, ensuring your products last longer and perform better. Contact our experts today to discuss how we can meet your specific laboratory needs!

Visual Guide

Related Products

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Custom PTFE Teflon Parts Manufacturer for PTFE Tweezers

People Also Ask

- What is the purpose of vacuum heat treatment? Achieve Superior Metallurgical Purity and Performance

- What safety precautions would you have to consider during quench? Ensure Safe Vacuum Oil Quenching with Nitrogen Control

- Is heat Cannot travel in a vacuum True or false? Discover How Heat Crosses the Void of Space

- What happens to heat generated in a vacuum? Mastering Thermal Control for Superior Materials

- What are the advantages of vacuum firing? Achieve Ultimate Material Purity and Performance