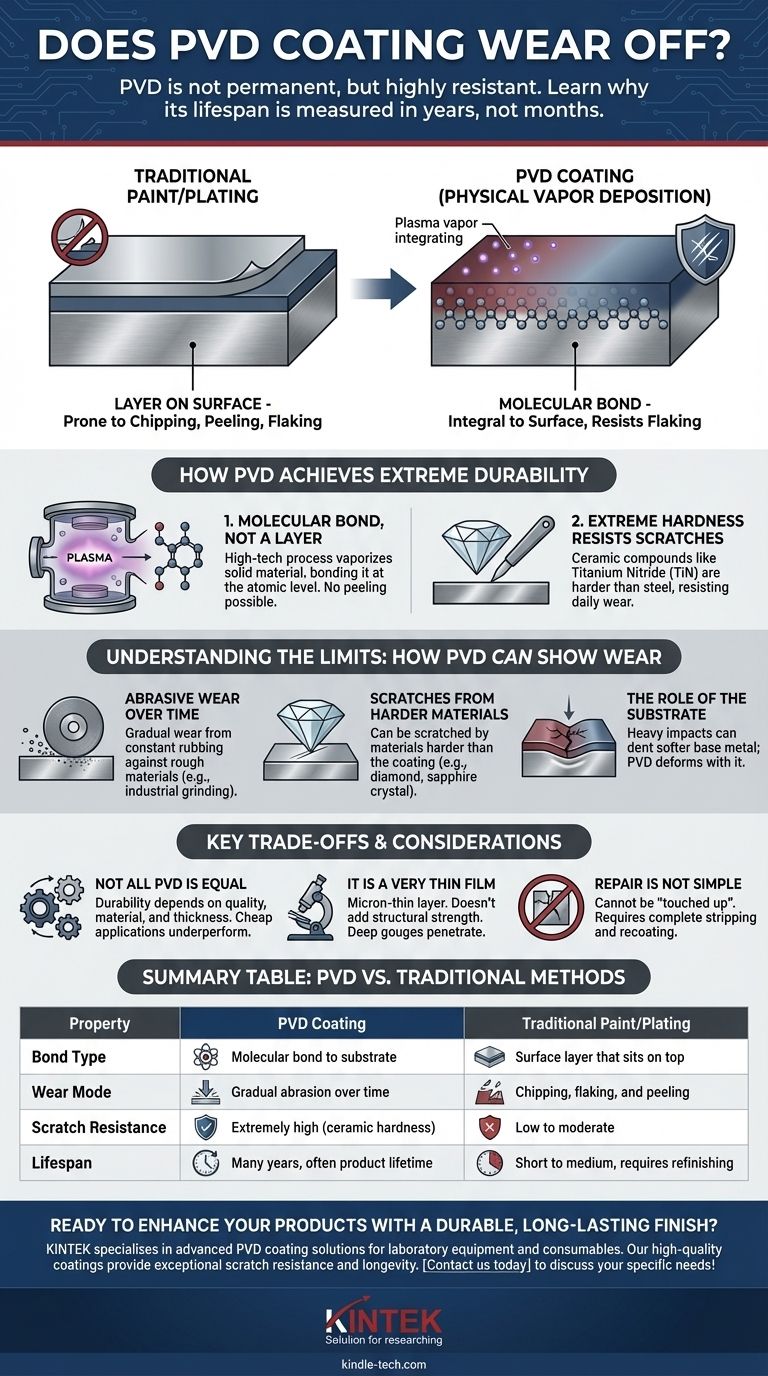

While no coating is truly permanent, a high-quality PVD finish does not wear off under normal conditions in the way that paint or traditional plating does. The Physical Vapor Deposition (PVD) process creates a molecular bond that is exceptionally hard and durable, meaning it resists scratches and does not flake, peel, or tarnish. Its lifespan is typically measured in many years, often for the entire life of the product.

The core issue is not if PVD wears off, but how it withstands damage. Unlike paint or plating that fails by chipping and flaking, PVD's failure mode is gradual abrasion from extended contact with harder materials, a process that takes a significant amount of force and time.

How PVD Achieves Extreme Durability

To understand the longevity of a PVD coating, you must first understand that it is fundamentally different from traditional coating methods.

It's a Molecular Bond, Not a Layer of Paint

PVD is not a liquid coating that dries on a surface. It is a high-tech vacuum deposition process where a solid material (like titanium or zirconium nitride) is vaporized into plasma and then molecularly bonded to the surface of the base material, or substrate.

This atomic-level bond is the key. The coating becomes an integral part of the surface itself, which is why it cannot flake or peel off.

Extreme Hardness Resists Scratches

The materials used for PVD coatings are ceramic compounds that are incredibly hard—often significantly harder than the steel they are applied to. For example, Titanium Nitride (TiN), a common PVD material, is known for its exceptional hardness.

This hardness is what provides superior resistance to the daily scuffs, scrapes, and scratches that would quickly degrade a traditional painted, powder-coated, or electroplated finish.

Understanding the Limits: How PVD Can Show Wear

While exceptionally durable, a PVD coating is not indestructible. Understanding its limitations gives you a realistic expectation of its performance.

Abrasive Wear Over Time

The most common way for PVD to show wear is through slow, gradual abrasion. If the coated surface is constantly rubbed against a rough, abrasive material (like sandpaper, concrete, or industrial grinding media), it will eventually wear down.

However, for most consumer products like watches, faucets, or hardware, this level of abrasion is highly unlikely.

Scratches from Harder Materials

A fundamental principle of materials science is that a harder material will scratch a softer one. While PVD coatings are extremely hard, they can be scratched by materials that are even harder, such as a diamond, sapphire crystal, or silicon carbide (a component of some sandpapers).

This results in a fine scratch on the surface, not a chip or a flake.

The Role of the Substrate

The material underneath the PVD coating matters. If you apply a very hard PVD coating to a soft base metal like aluminum, a hard impact can dent the aluminum. The PVD coating is strong enough to deform with the dent rather than crack, but the damage to the underlying product will still be visible.

Key Trade-offs and Considerations

Choosing PVD involves weighing its benefits against a few practical realities.

Not All PVD is Created Equal

The term "PVD" describes a process, not a single standard. The durability of the coating depends heavily on the quality of the application, the specific coating material used, and its thickness. A cheap PVD application will not perform as well as a high-end, industrial-grade one.

It Is a Very Thin Film

PVD coatings are remarkably thin, often measured in microns. While this film is incredibly hard, it does not add structural integrity to the part. A deep gouge from a sharp, hard object can penetrate the thin coating and expose the base metal underneath.

Repair Is Not Simple

You cannot "touch up" a damaged PVD coating. Repairing a scratch or worn area requires the entire object to be chemically stripped of the old coating and then completely recoated, a process that can be costly and is often impractical for consumer goods.

Making the Right Choice for Your Goal

PVD is an outstanding choice for surface durability, but its suitability depends on your specific application and expectations.

- If your primary focus is aesthetics and daily wear resistance (e.g., a watch, faucet, or high-end hardware): PVD is an elite choice that will maintain its original color and finish for many years, far outlasting traditional alternatives.

- If your primary focus is extreme industrial use (e.g., cutting tools or high-friction components): PVD dramatically extends the usable life of the tool but is considered a sacrificial layer that will eventually wear and require re-coating as part of a planned maintenance cycle.

- If you are concerned about heavy impacts and deep gouges: Remember that PVD protects the surface finish but will not prevent dents or damage to the underlying material if it is impacted with sufficient force.

By understanding that PVD offers exceptional resistance to wear rather than total invulnerability, you can confidently choose it for its superior, long-lasting finish.

Summary Table:

| Property | PVD Coating | Traditional Paint/Plating |

|---|---|---|

| Bond Type | Molecular bond to substrate | Surface layer that sits on top |

| Wear Mode | Gradual abrasion over time | Chipping, flaking, and peeling |

| Scratch Resistance | Extremely high (ceramic hardness) | Low to moderate |

| Lifespan | Many years, often product lifetime | Short to medium, requires refinishing |

Ready to enhance your products with a durable, long-lasting finish?

At KINTEK, we specialize in advanced PVD coating solutions for laboratory equipment and consumables. Our high-quality coatings provide exceptional scratch resistance and longevity, ensuring your lab tools and components maintain their performance and appearance for years.

Whether you need to protect sensitive instruments, improve wear resistance on consumables, or upgrade your lab's hardware, our expertise in PVD technology delivers superior results.

Contact us today to discuss how KINTEK's PVD coatings can meet your specific laboratory needs!

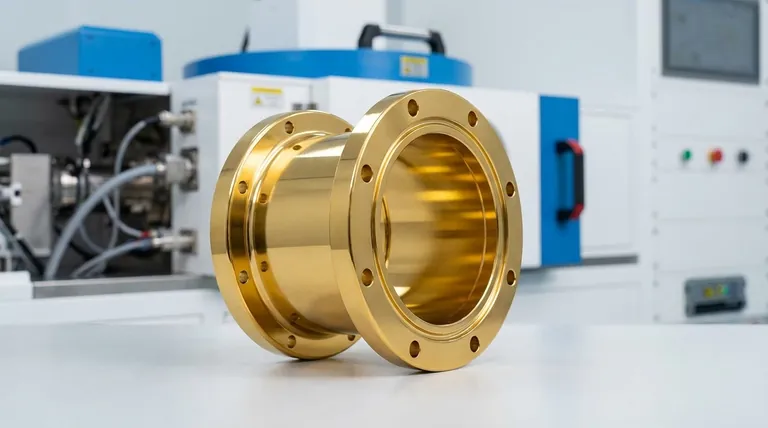

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition