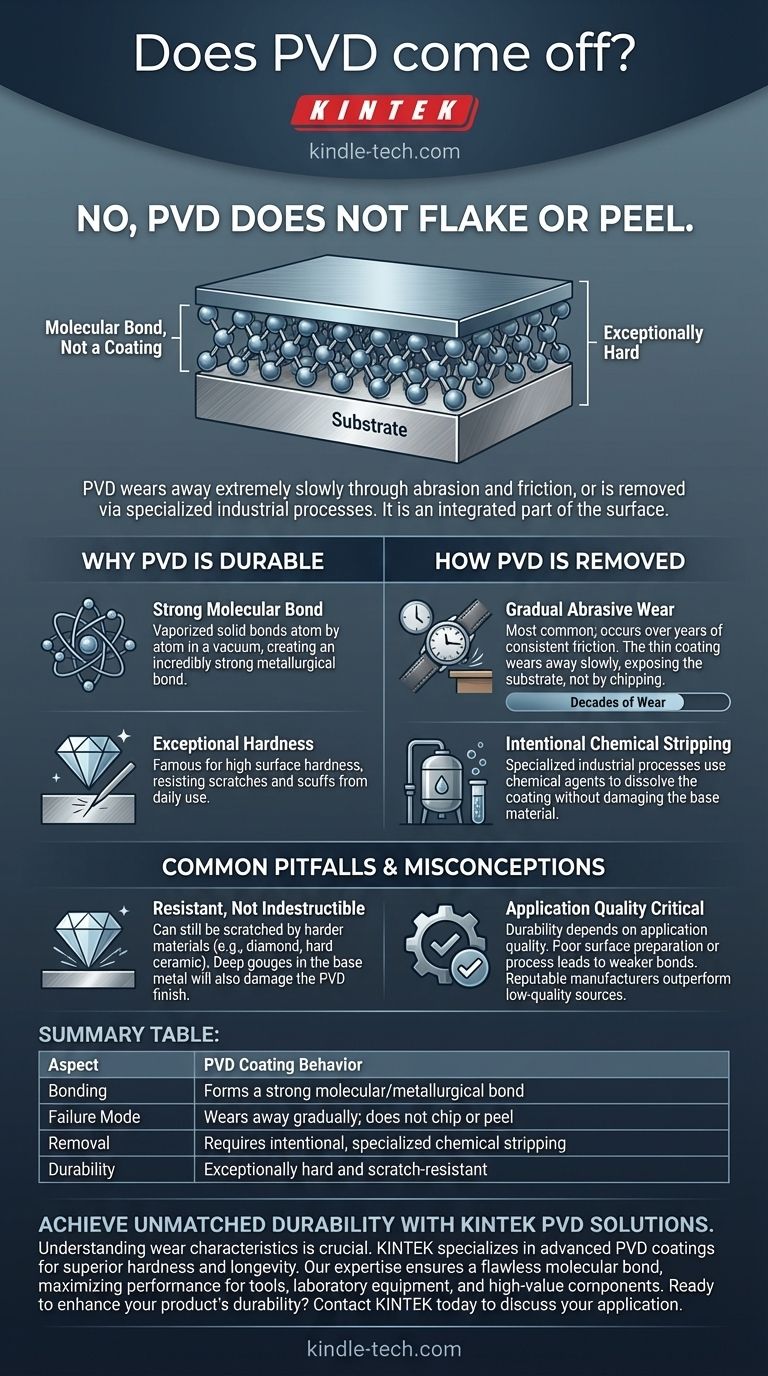

No, a PVD coating does not simply "come off" by flaking or peeling. Under normal circumstances, Physical Vapor Deposition (PVD) coatings are exceptionally durable because they form a molecular bond with the underlying material. However, they are not indestructible and can be removed through gradual wear over a very long time or through intentional chemical processes.

The core issue is not whether PVD comes off, but how it does. Unlike paint or traditional plating that can chip and flake, a PVD coating wears away extremely slowly through abrasion and friction, or it can be removed with specialized industrial processes.

What Makes PVD So Durable?

To understand why PVD finishes are so robust, we need to look at how they are applied. This isn't a layer of paint sitting on top of a surface; it's an integrated part of it.

A Molecular Bond, Not a Coating

The PVD process takes place in a vacuum chamber where a solid material (like titanium or zirconium) is vaporized into plasma. This vapor is then bonded to the object's surface atom by atom.

This creates a metallurgical bond that is incredibly strong, ensuring the coating won't delaminate, peel, or flake off on its own.

Exceptional Hardness

PVD coatings are famous for their high surface hardness, often compared to that of a diamond. This characteristic makes them highly resistant to scratches and scuffs from daily use.

This is why PVD is a preferred finish for high-contact items like watch cases, faucets, and industrial tools.

How a PVD Coating Can Be Removed

While PVD is highly resistant to failure, it is not a permanent, invincible shield. There are two primary ways a PVD coating is removed.

Gradual Abrasive Wear

This is the most common way a PVD finish shows age. Over many years of consistent friction, the coating can slowly wear thin and expose the substrate beneath.

Think of the clasp on a watch bracelet rubbing against a desk for a decade. The wear is a slow, gradual process, not a sudden chipping or failure. The coating is so thin—often only a micron—that it wears away rather than breaking off.

Intentional Chemical Stripping

Specialized industrial processes exist to remove PVD coatings without damaging the base material.

These "de-coating" methods use specific chemical agents to dissolve the coating layers. This is typically done to refinish or re-coat a high-value item, not something that happens accidentally.

Common Pitfalls and Misconceptions

Understanding the limitations of PVD is just as important as knowing its strengths. This helps set realistic expectations for the longevity of your product.

It Is Resistant, Not Indestructible

A PVD finish can still be scratched by a material that is harder than it is. While it easily resists car keys or a door frame, a diamond or hard ceramic could damage the surface.

Furthermore, PVD does not make the underlying material stronger. A deep gouge that deforms the base metal will damage the PVD finish along with it.

Application Quality Is Critical

The durability of a PVD coating is highly dependent on the quality of its application. A poorly prepared surface or an improperly executed process can lead to a much weaker bond.

This is why a PVD finish from a reputable manufacturer will almost always outperform one from a low-cost, low-quality source.

Making the Right Choice for Your Goal

Ultimately, choosing a PVD-coated product is about understanding its unique properties.

- If your primary focus is everyday durability for items like watches or faucets: PVD is an outstanding choice that will resist scratches and tarnish for years without flaking or peeling.

- If your primary focus is extreme performance for tools or industrial parts: PVD drastically extends the lifespan but should be viewed as a high-performance, wearable surface that will eventually require re-coating in high-friction zones.

- If you are concerned about refinishing a product in the future: Be aware that removing a PVD coating requires specialized professional services and is not a simple DIY task.

By understanding that PVD wears rather than flakes, you can correctly assess its superior durability for almost any application.

Summary Table:

| Aspect | PVD Coating Behavior |

|---|---|

| Bonding | Forms a strong molecular/metallurgical bond with the substrate. |

| Failure Mode | Wears away gradually through abrasion; does not chip or peel. |

| Removal | Requires intentional, specialized chemical stripping processes. |

| Durability | Exceptionally hard and scratch-resistant, but not indestructible. |

Achieve Unmatched Durability with KINTEK PVD Solutions

Understanding the wear characteristics of PVD is crucial for selecting the right coating for your laboratory equipment, tools, or high-value components. KINTEK specializes in advanced PVD coatings that deliver superior hardness and longevity, ensuring your products withstand demanding conditions.

Our expertise ensures a flawless molecular bond to your substrates, maximizing performance and lifespan. Whether you're developing medical instruments, precision tools, or durable consumer goods, our solutions are tailored to meet your specific needs.

Ready to enhance your product's durability with a coating that wears correctly?

Contact KINTEK today to discuss how our PVD expertise can benefit your application.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Custom CVD Diamond Coating for Lab Applications

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Cold Trap Direct Cold Trap Chiller

- Isostatic Molding Pressing Molds for Lab

People Also Ask

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition