In short, no. PVD-coated stainless steel does not fade in the way that paint or dyed fabrics do. The color is created by a durable, ceramic-like material that is molecularly bonded to the steel's surface, so it cannot lose its hue over time. Any color loss is the result of the coating itself being physically worn away through extreme abrasion, not from chemical change or UV exposure.

The durability of PVD stainless steel is not a question of fading but of abrasion resistance. The color is an integral part of an exceptionally hard coating, and it remains vibrant unless the coating itself is physically worn through by friction or impact.

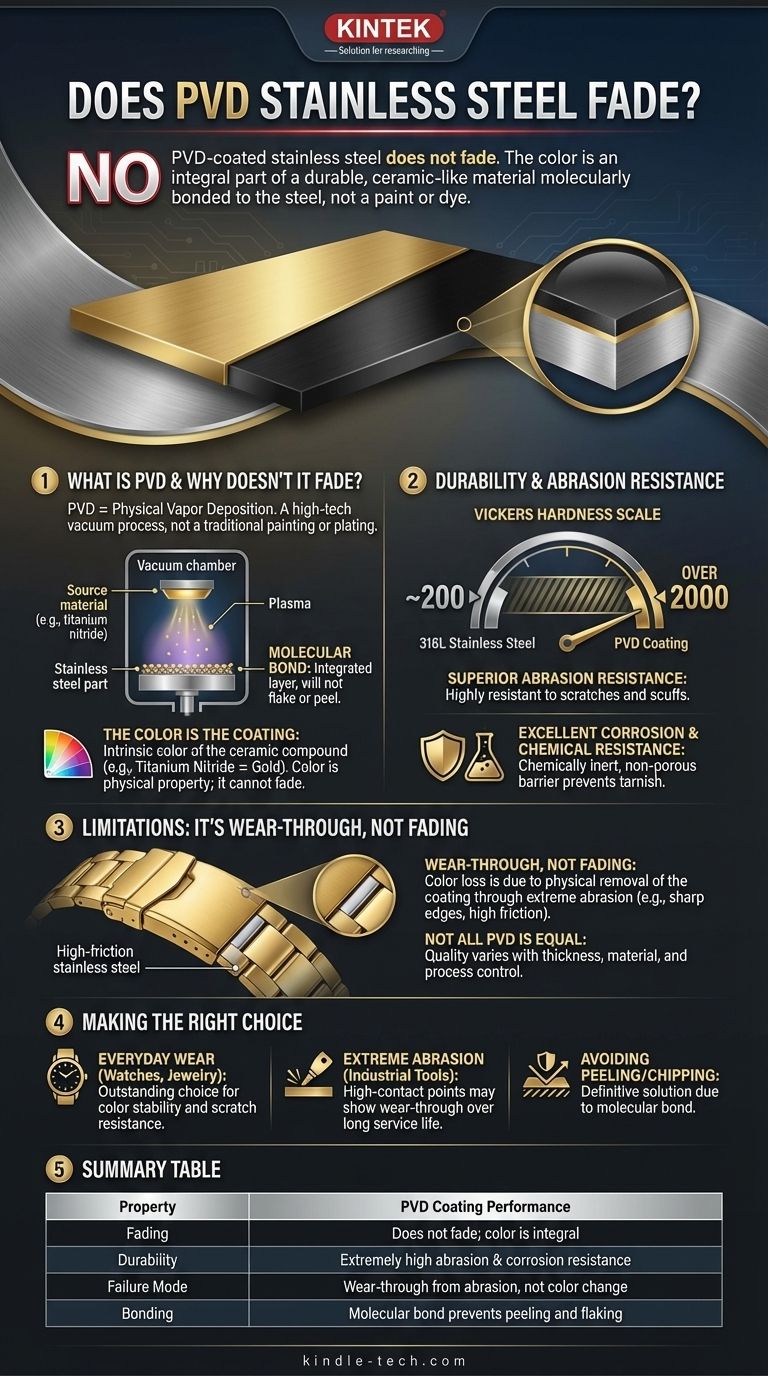

What is PVD and Why Doesn't It "Fade"?

To understand the durability of PVD, you must first understand that it is not a paint or a traditional plating process. It is a high-tech vacuum deposition process that fundamentally changes the surface of the steel.

A Molecular Bond, Not a Layer of Paint

PVD stands for Physical Vapor Deposition. In this process, the stainless steel part is placed in a vacuum chamber, and a solid material (often a ceramic like titanium nitride) is vaporized into a plasma. This vapor then deposits onto the steel, forming a new, extremely hard surface that is molecularly bonded to the substrate.

This is not a separate layer sitting on top of the steel. It is an integrated layer that becomes part of the steel's surface, which is why it will not flake or peel off.

The Color is the Coating

The colors in PVD—from black and gold to bronze and blue—are the intrinsic color of the ceramic compound being applied. For example, Titanium Nitride produces a gold color, while Titanium Carbonitride can create black or gray finishes.

Because the color is the physical property of the coating material itself, it cannot "fade." A gold PVD coating is gold all the way through the coating layer. The only way to remove the color is to physically remove the coating itself.

The Real Question: How Durable Is It?

Since PVD doesn't fade, the practical question becomes one of wear and tear. The answer is that PVD coatings are exceptionally durable and designed to withstand significant stress.

Superior Abrasion Resistance

The ceramic compounds used in PVD are extremely hard, often measuring over 2000 on the Vickers hardness scale. For comparison, 316L stainless steel is typically around 200. This makes the PVD surface highly resistant to the scratches and scuffs of daily use.

Excellent Corrosion and Chemical Resistance

The PVD layer is chemically inert and non-porous. This creates a protective barrier that shields the underlying stainless steel from sweat, saltwater, acids, and other corrosive elements, preventing tarnish and discoloration.

Understanding the Trade-offs and Limitations

While incredibly tough, PVD coating is not indestructible. It is crucial to understand its limits to have realistic expectations for your product's longevity.

It's Wear-Through, Not Fading

When a PVD-coated item loses its color, it is almost always on sharp edges, corners, or high-friction areas like a watch clasp. This happens when the object is repeatedly rubbed against a harder or equally hard abrasive surface (like concrete, sand, or other metal tools).

This process physically grinds the thin coating away, eventually exposing the silver-colored stainless steel underneath. The color of the remaining coating does not change; a portion of the coating is simply gone.

Not All PVD Is Created Equal

The quality of a PVD finish can vary significantly. Factors like the thickness of the coating, the specific material used, and the quality control of the application process all impact its final durability. A cheaply applied, thin PVD coating will not perform as well as a thicker, high-quality coating from a reputable manufacturer.

Making the Right Choice for Your Goal

PVD is a superior coating technology for color, but its suitability depends on the product's intended use.

- If your primary focus is everyday wear (watches, jewelry, faucets): PVD is an outstanding choice, providing years of color stability and scratch resistance that far surpasses traditional plating methods.

- If your item will face extreme abrasion (industrial tools, military gear): While PVD offers excellent protection, expect that high-contact points may eventually show wear-through to the steel underneath over a long service life.

- If your main concern is avoiding peeling or chipping: PVD is the definitive solution, as its molecular bond prevents the flaking and chipping commonly seen in electroplating.

Understanding that PVD wears rather than fades empowers you to accurately judge the long-term value and appearance of your stainless steel products.

Summary Table:

| Property | PVD Coating Performance |

|---|---|

| Fading | Does not fade; color is integral to the coating |

| Durability | Extremely high abrasion and corrosion resistance |

| Failure Mode | Wear-through from abrasion, not color change |

| Bonding | Molecular bond prevents peeling and flaking |

Ready to integrate ultra-durable PVD coatings into your product line? KINTEK specializes in advanced lab equipment and consumables for surface treatment and testing. Our expertise ensures your PVD-coated stainless steel components meet the highest standards of durability and performance. Contact our experts today to discuss how we can support your laboratory and manufacturing needs.

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Stainless Steel Quick Release Vacuum Chain Three-Section Clamp

People Also Ask

- What is diamond coating film? A Thin Layer of Diamond for Extreme Performance

- Is diamond coating permanent? The Truth About Its Long-Lasting Durability

- What are the three types of coating? A Guide to Architectural, Industrial, and Special Purpose

- How are tools coated with diamond? Achieve Superior Hardness and Low Friction for Your Tools

- How thick is CVD diamond coating? Balancing Durability and Stress for Optimal Performance