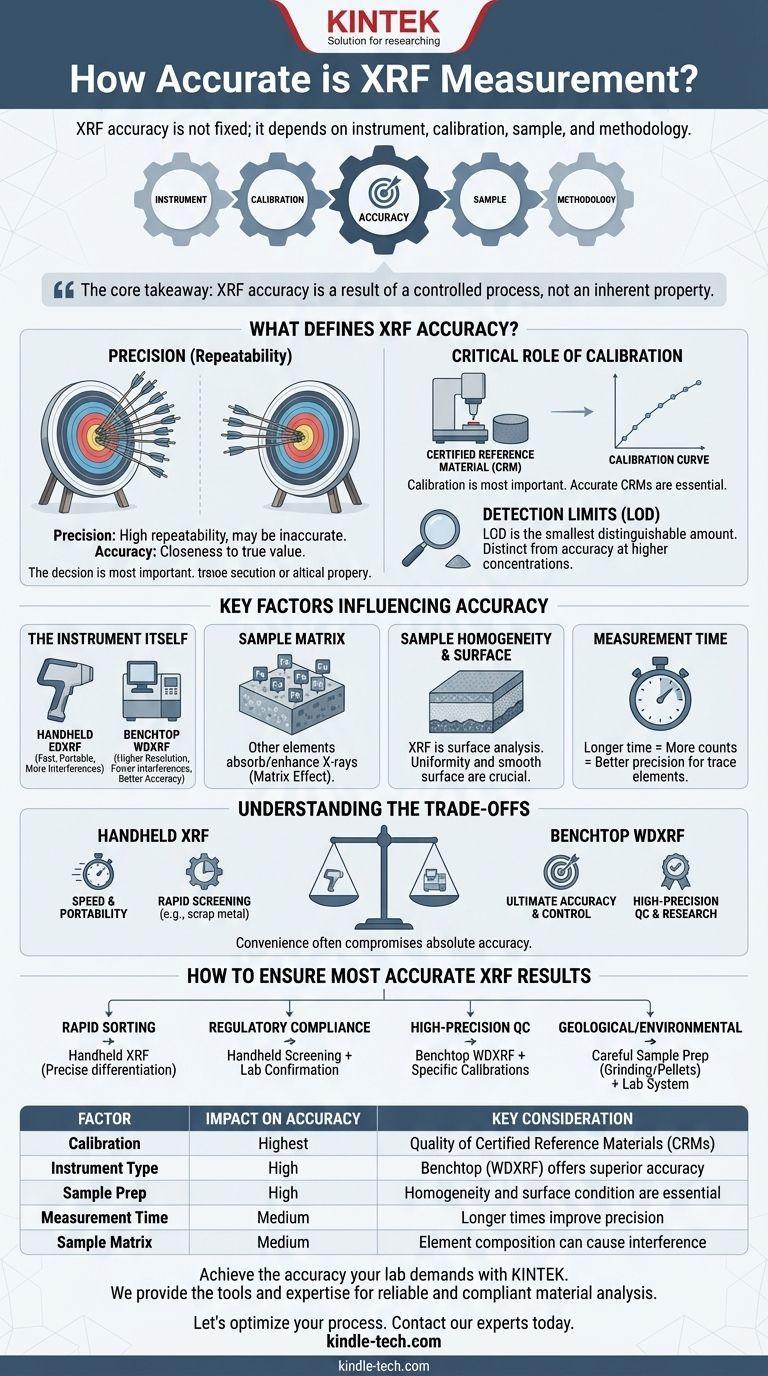

The accuracy of an X-ray fluorescence (XRF) measurement is not a single, fixed value. While it can be exceptionally accurate for certain applications—often achieving precision in the parts-per-million (ppm) range—its true accuracy is highly dependent on the instrument type, the calibration standard, the sample being analyzed, and the methodology used.

The core takeaway is that XRF accuracy is not an inherent property of the technology itself. It is a result of a controlled process where the instrument, calibration, and sample preparation are all optimized for a specific analytical goal.

What Defines "Accuracy" in XRF?

To understand the accuracy of XRF, we must first clarify the terminology. In analytical science, "accuracy" is often discussed alongside "precision" and "detection limits."

Precision vs. Accuracy

Precision refers to the repeatability of a measurement. If you measure the same sample ten times and get nearly identical results, your measurement is highly precise.

Accuracy, however, refers to how close a measurement is to the true, accepted value. An XRF analyzer can be very precise but consistently inaccurate if it is not calibrated correctly.

The Critical Role of Calibration

Calibration is the single most important factor determining XRF accuracy. The process involves measuring samples with known elemental concentrations, called certified reference materials (CRMs), to create a calibration curve.

An instrument is only as accurate as the reference materials it was calibrated with. Using the wrong calibration or low-quality standards will produce inaccurate results, even on the most advanced machine.

Detection Limits (LOD)

The Limit of Detection (LOD) is the smallest amount of an element that the analyzer can reliably distinguish from a blank sample. This is not the same as accuracy.

An instrument might have a low LOD for lead (e.g., 1 ppm) but still be inaccurate at higher concentrations (e.g., reading 450 ppm when the true value is 500 ppm) if its calibration is poor.

Key Factors That Influence XRF Accuracy

Several variables can significantly impact the quality of an XRF measurement. Understanding them is crucial for interpreting your results.

The Instrument Itself

There are two main types of XRF: Energy Dispersive (EDXRF) and Wavelength Dispersive (WDXRF).

EDXRF is common in portable, handheld units. It is fast and convenient but can suffer from spectral peak overlaps, where signals from different elements interfere with each other, reducing accuracy for certain combinations.

WDXRF is found in larger, lab-based benchtop systems. It offers superior spectral resolution, leading to fewer interferences, lower detection limits, and generally higher accuracy.

The Sample Matrix

The "matrix" refers to all the other elements in the sample besides the element of interest. These other elements can absorb or enhance the fluorescent X-rays, skewing the results. This is known as a matrix effect.

For example, accurately measuring a light element in a heavy metal alloy is much more challenging than measuring it in a plastic polymer. Proper calibration must account for these effects.

Sample Homogeneity and Surface

XRF is a surface analysis technique. The X-rays only penetrate a few micrometers to millimeters into the sample.

If the sample is not homogeneous (uniform in composition), the surface measurement will not represent the bulk material. Likewise, a rough, uneven, or contaminated surface will scatter X-rays and produce poor, unreliable data.

Measurement Time

A longer measurement time allows the detector to collect more X-ray counts, which improves the signal-to-noise ratio. This directly leads to better statistical precision and can improve the accuracy of trace element analysis.

Understanding the Trade-offs: Handheld vs. Benchtop

The choice between a portable and a lab-based instrument is a fundamental trade-off between convenience and control.

Speed and Portability

Handheld XRF excels at rapid screening and identification. It is invaluable for applications like scrap metal sorting, Positive Material Identification (PMI) in plants, and environmental field screening. Its accuracy is more than sufficient for these sorting and go/no-go tasks.

Ultimate Accuracy and Control

Benchtop WDXRF provides the highest level of accuracy and reliability. The controlled lab environment allows for ideal sample preparation (like grinding and pressing pellets), the use of vacuum or helium atmospheres to measure light elements, and more powerful components for lower detection limits.

The Cost of Compromise

The convenience of handheld XRF comes at the cost of some analytical control. Environmental factors, variable sample surfaces, and the limitations of EDXRF technology mean it will rarely match the absolute accuracy of a high-end benchtop system.

How to Ensure the Most Accurate XRF Results

To get the most out of the technology, align your methodology with your analytical goal.

- If your primary focus is rapid material sorting (e.g., scrap metal alloys): A handheld XRF is highly effective; absolute accuracy is less critical than precise differentiation between known grades.

- If your primary focus is regulatory compliance (e.g., RoHS, CPSIA): Handheld XRF is an excellent screening tool, but failures often require confirmation with more accurate lab-based methods.

- If your primary focus is high-precision quality control (e.g., aerospace): A benchtop WDXRF system with specific calibrations using certified reference materials is the required standard for maximum accuracy.

- If your primary focus is geological or environmental analysis: Careful sample preparation, such as grinding and pressing samples into uniform pellets, is non-negotiable for achieving accurate quantitative results.

Ultimately, treating XRF not as a simple point-and-shoot device but as a scientific instrument whose variables you can control is the key to unlocking its true analytical power.

Summary Table:

| Factor | Impact on Accuracy | Key Consideration |

|---|---|---|

| Calibration | Highest | Quality of Certified Reference Materials (CRMs) is critical |

| Instrument Type | High | Benchtop (WDXRF) offers superior accuracy to handheld (EDXRF) |

| Sample Preparation | High | Homogeneity and surface condition are essential |

| Measurement Time | Medium | Longer times improve precision for trace elements |

| Sample Matrix | Medium | Composition of other elements can cause interference |

Achieve the accuracy your lab demands with KINTEK.

XRF accuracy is not a given—it's the result of using the right equipment and methodology. Whether you need the rapid screening capability of a handheld analyzer or the high-precision data from a benchtop WDXRF system, KINTEK has the solution. We specialize in lab equipment and consumables, providing the tools and expertise to ensure your material analysis is reliable and compliant.

Let's optimize your process. Contact our experts today for a personalized consultation.

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Benchtop Laboratory Vacuum Freeze Dryer

- Benchtop Laboratory Freeze Dryer for Lab Use

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

People Also Ask

- What are the advantages of a power press? High-Speed, High-Volume Manufacturing Solution

- How much does it cost to build a hydraulic press? A DIY Guide to Budgeting for Power and Safety

- What is the maximum force of a hydraulic press? Discover How Force is Generated and Scaled

- What is the hydraulic forging process? Master the Art of High-Strength Metal Forming

- What would happen to a diamond in a hydraulic press? It Shatters Due to Brittleness, Not Lack of Hardness

- What are the advantages and disadvantages of transfer moulding? Achieve Precision for Complex Thermoset Parts

- What is the factor of safety for a hydraulic press? It's a System, Not a Single Number

- What is the use of a hydraulic pellet press? Transform Powders into Precise Samples for Analysis